A kind of drilling and grinding equipment for electronic products

A technology of electronic products and equipment, which is applied in the field of drilling and grinding equipment, can solve the problems of low work efficiency, damage and inconvenience of small processed parts, and achieve the effects of reduced scrap rate, space saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

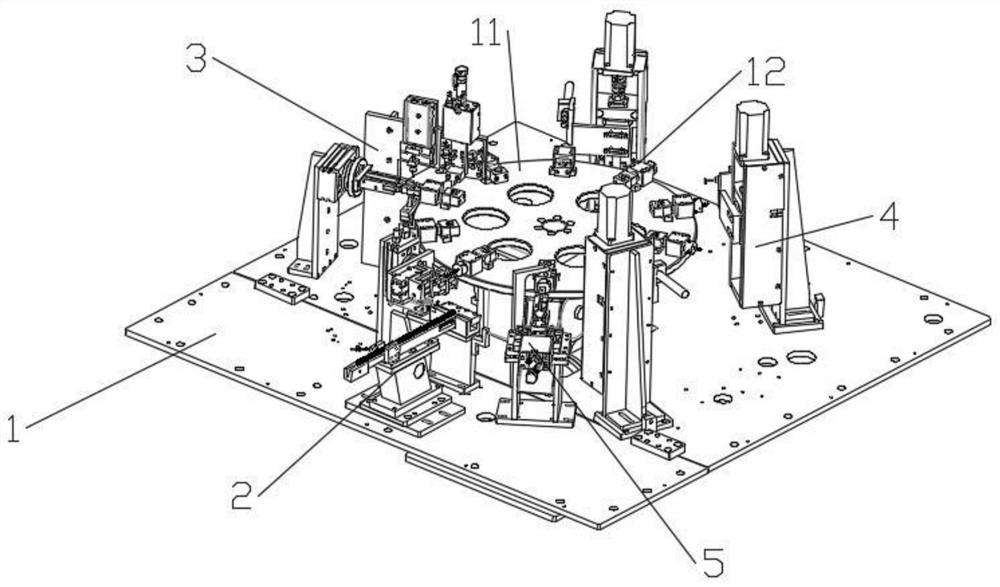

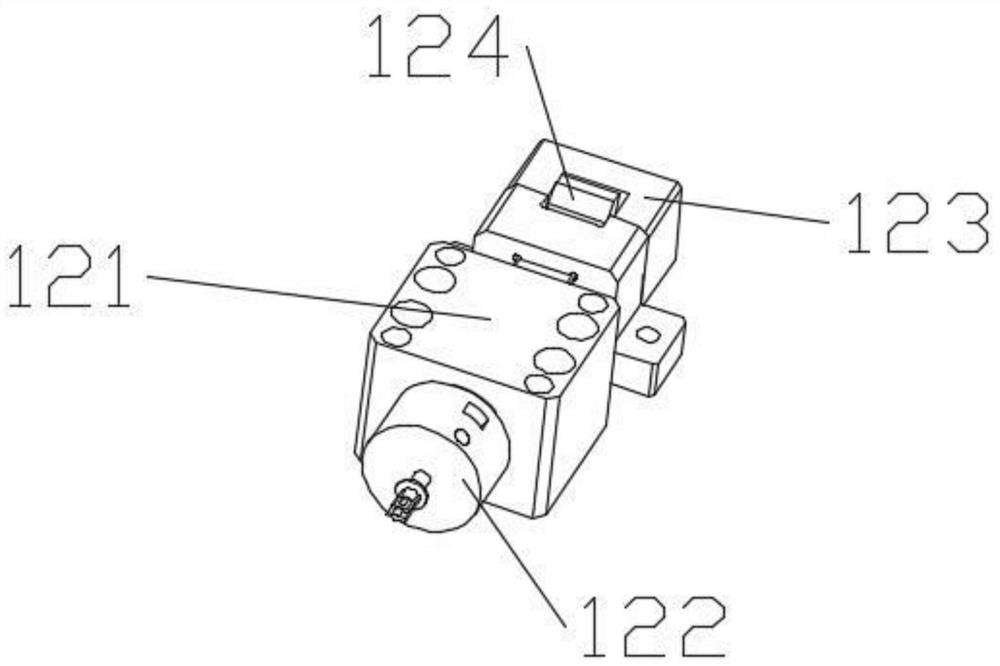

[0043] Such as figure 1 As shown, a kind of punching and grinding equipment for electronic products proposed by the present invention includes a frame 1, on which a turntable 11 is rotated, and a plurality of toolings 12 are uniformly arranged on the outer edge of the turntable 11, The outer periphery of the turntable 11 is sequentially provided with a feeding mechanism 2, a punching mechanism 3, a grinding mechanism 4 and a blanking mechanism 5;

[0044] It is conceivable that the turntable 11 is also connected with a divider for the rotation of the turntable 11, which is a well-known technology for those skilled in the art, and will not be described in detail again.

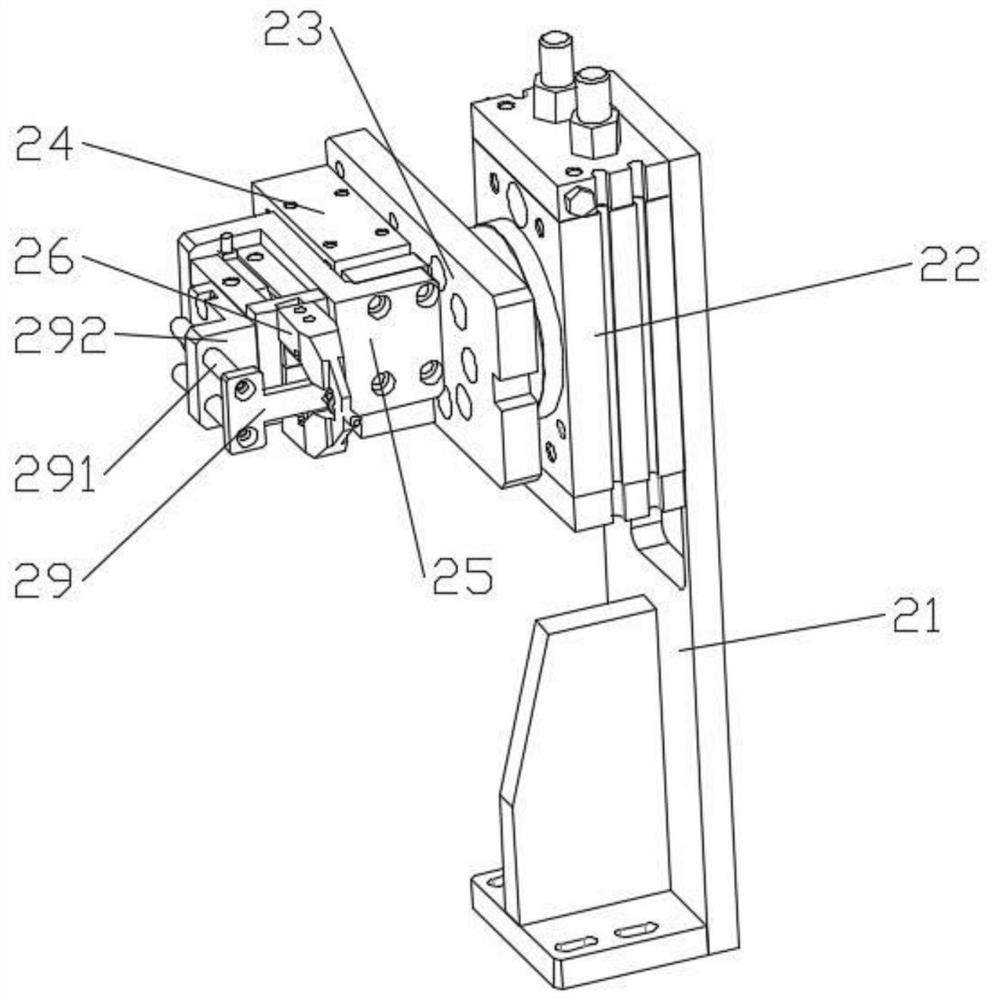

[0045] The feeding mechanism 2 includes a feeding fixed se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com