Production of special sectional flate steel for air-conditioner vane

A production method and technology for air conditioners, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low precision, complex production process, and production equipment that is not as good as them, achieving less processing volume, good dimensional stability, Carbide fine and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

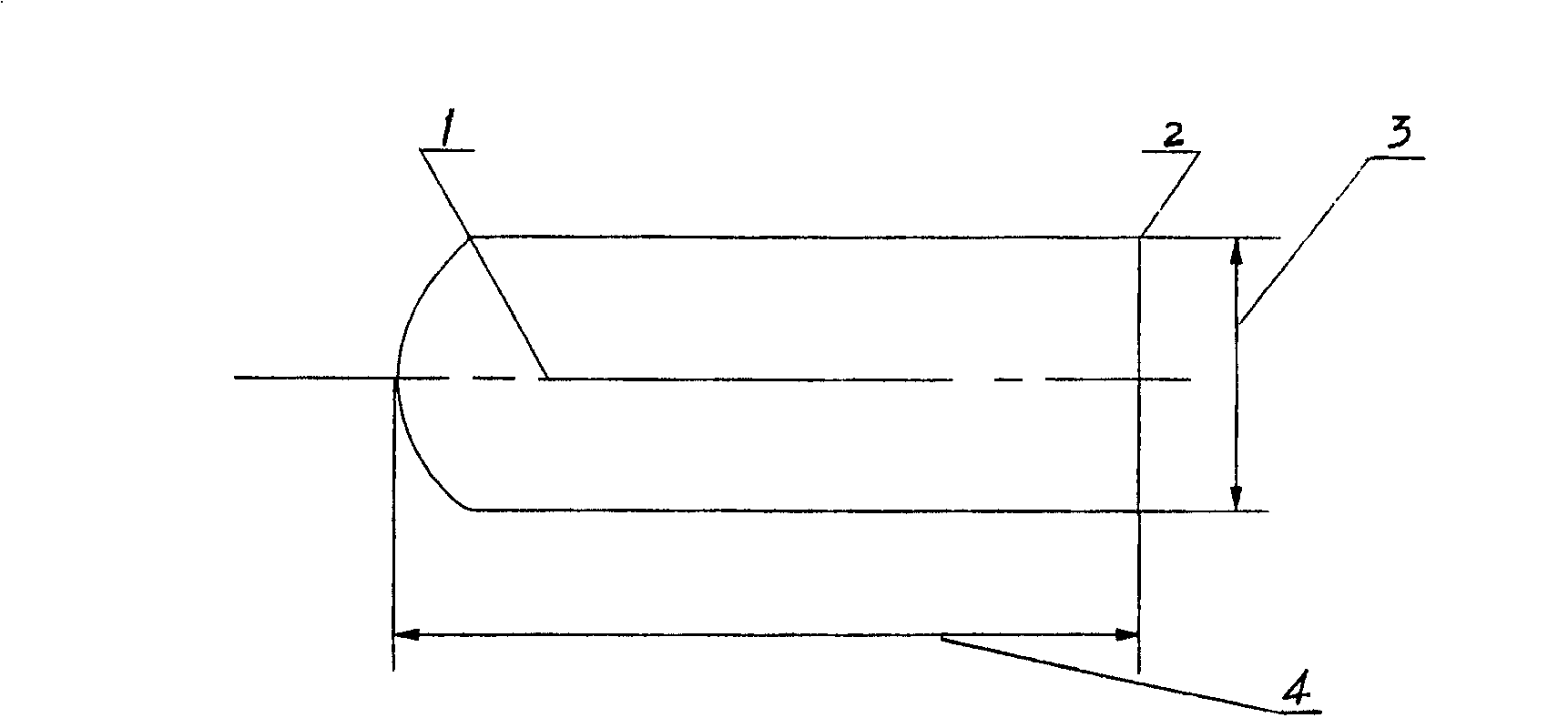

[0014] When using this method to produce special-shaped flat steel for air conditioner blades, the following production process is adopted:

[0015] Treated billet → rolled into slab on 250×5 tandem mill and annealed → cold rolled and annealed on 200 mm two-roll cold rolling mill, then first time on 10 ton straight drawer Drawing and annealing → second drawing to finished size on a 10-ton straight bar drawing machine → removing surface contamination → plane and side straightening on a 9-roll cantilever straightening machine, and one by one according to the set length Cutting → check the appearance and dimensions of the finished product → anti-rust, packaging, and storage. Corresponding to the above process, do the following 6 control methods:

[0016] 1. Control of the size of the hot-rolled slab, the unit of size is mm:

[0017] (Thickness T+1~1.5) -0.30 +0.10 ×(width W+1~1.5) -0.40 +0.20 ×r 0.80~1.00

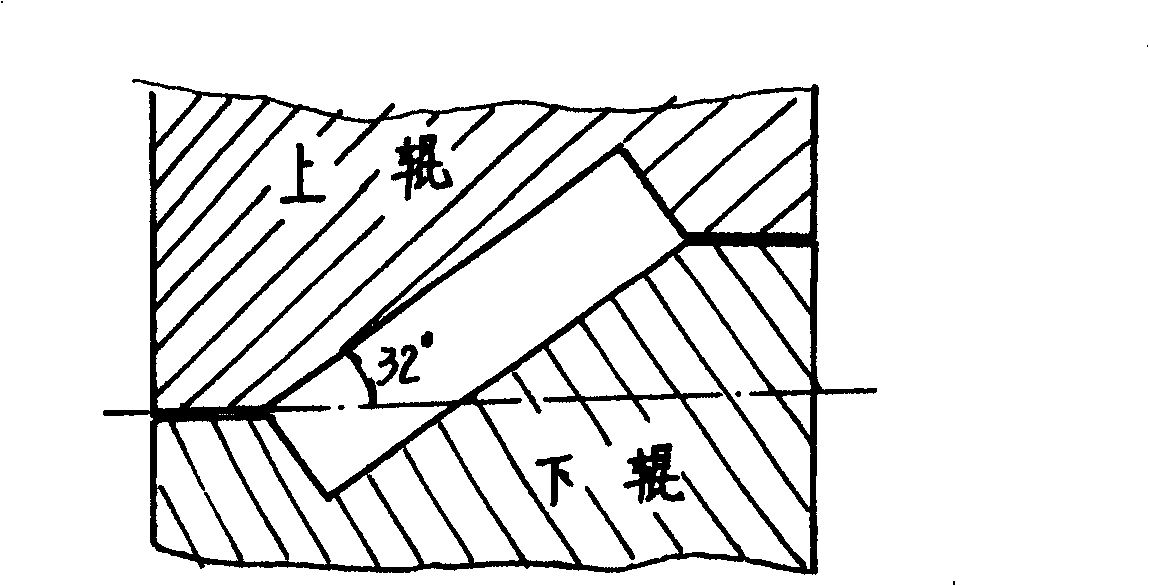

[0018] 2. The control of the drawing amount before the finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com