Double-pump parallel hydraulic flow conversion device and roller drive system of rubber mixing machine

A technology of variable flow device and rubber mixing machine, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc. It can solve problems such as difficulty in adapting to rubber mixing process requirements, lack of speed regulation technology, etc., and achieve responsiveness The effect of fast speed and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

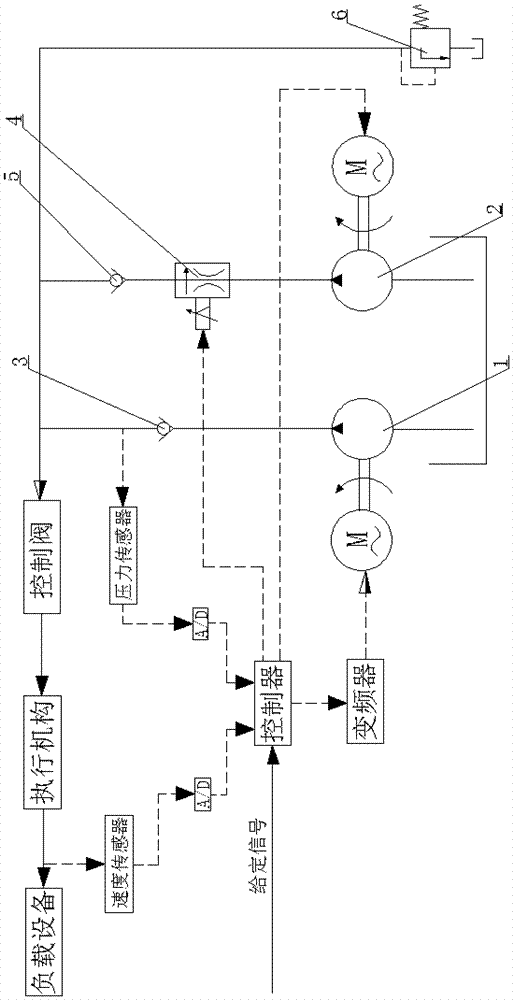

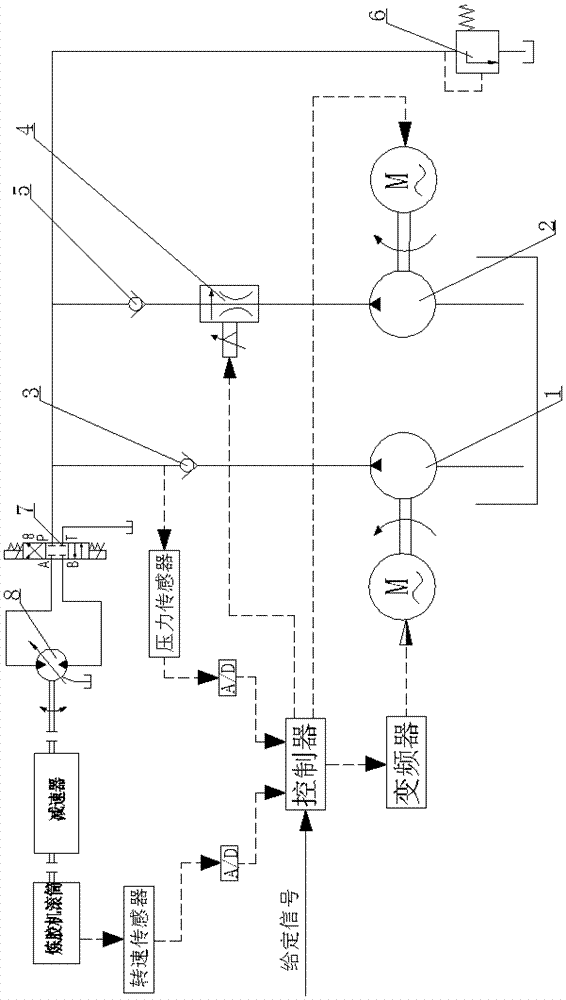

[0032] The embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

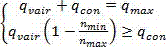

[0033] like figure 1 The shown dual-pump parallel hydraulic converter device includes a first hydraulic pump 1; a second hydraulic pump 2 connected in parallel with the first hydraulic pump 1; an oil inlet connected to the oil outlet of the first hydraulic pump 1 through an oil pipe The first check valve 3; the proportional speed regulating valve 4 connected with the oil outlet of the second hydraulic pump 2 through the oil pipe; the second check valve 5 whose oil inlet is connected with the oil outlet of the proportional speed regulating valve 4 through the oil pipe ;The control valve whose pressure oil port is connected with the oil outlet of the first check valve 3 and the second check valve 5 through the oil pipe; the actuator connected with the working oil port of the control valve through the oil pipe; the load device connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com