Multifunctional sludge pump room

A sludge pump house, multi-functional technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of inconvenient operation and management, high project investment, large floor area, etc., to achieve simplified operation management mode, operation management Convenience and low engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

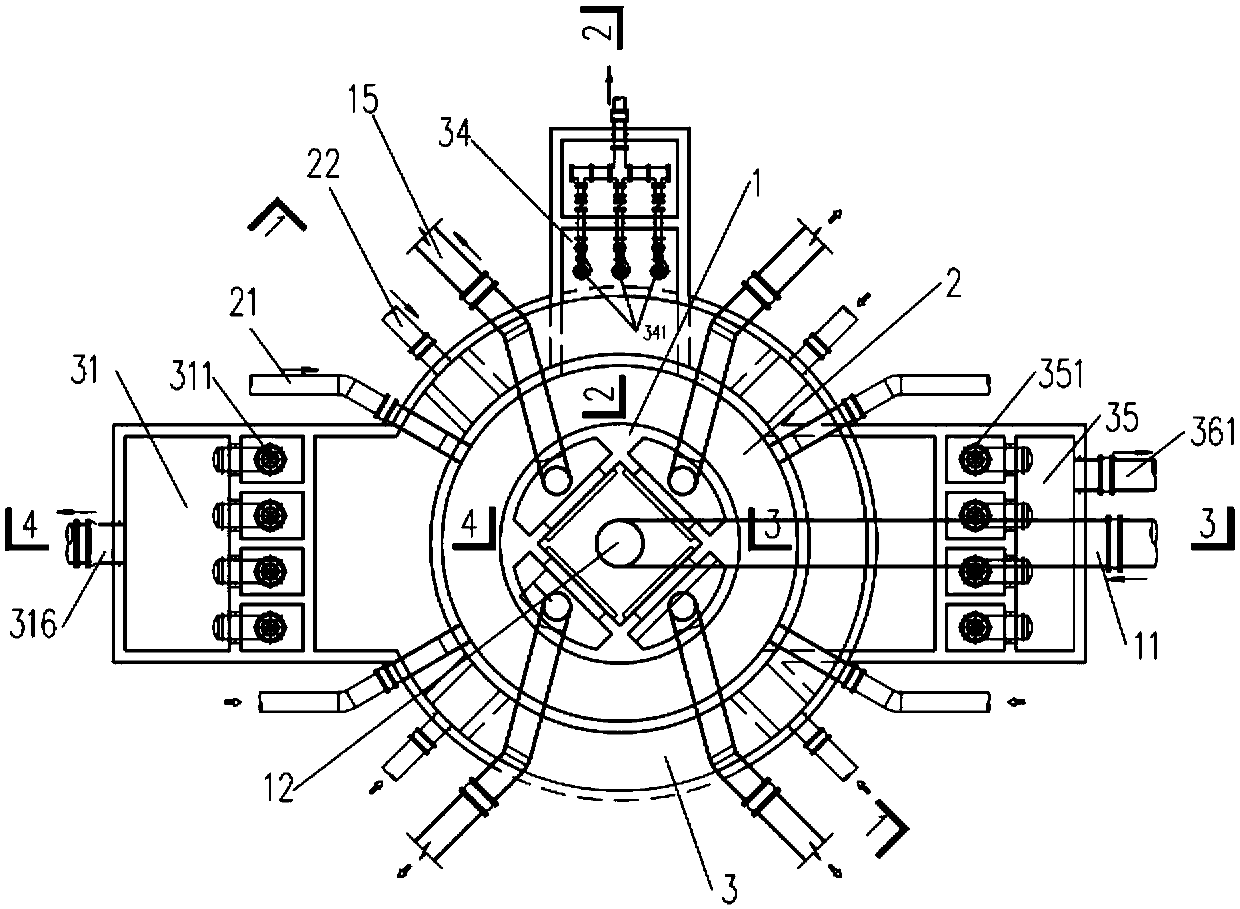

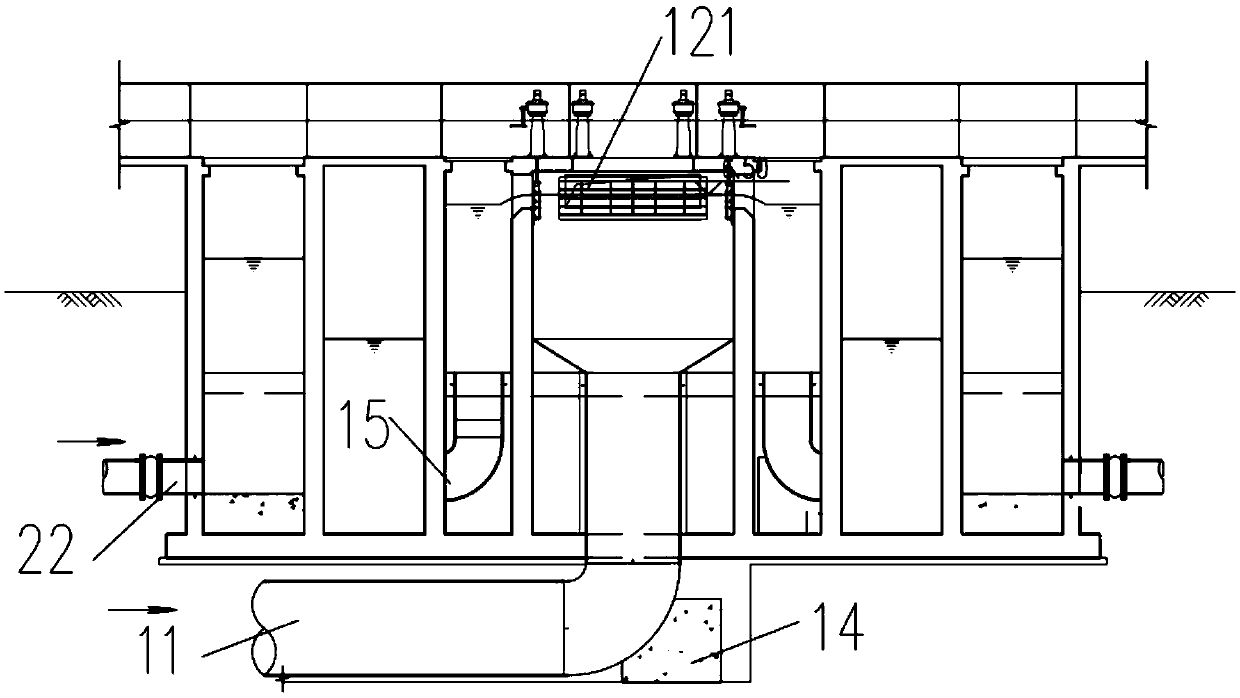

[0025] like Figure 1 to Figure 5 As shown, the present embodiment proposes a multifunctional sludge pump room, which includes an intermediate lifting pump room 31, a return sludge pump room 35, a surplus sludge pump room 34, and a water distribution well 12, wherein , the middle lifting pump room 31, the return sludge pump room 35, the remaining sludge pump room 34 and the water distribution well 12 are integrated and concentrated in a concentric circle manner.

[0026] Specifically, as figure 1 As shown, the concentric circles include three circles, which are the central circle 1, the middle circle 2 and the outer circle 3 from the inside to the outside. Among them, the middle lifting pump room 31 , the return sludge pump room 35 and the remaining sludge pump room 34 are respectively arranged in the outer ring 3 . Wherein, the middle ring 2 is connected with the return sludge pipe 21 of the secondary settling tank, and the outer ring 3 is connected with the outlet pipe 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com