Arch rib face internal multi-point restrained and distributed tied-arch bridge

A multi-point constraint, tied arch bridge technology, applied in arch bridges, bridges, bridge maintenance and other directions, can solve the problems of increasing foundation construction costs, not easy to build old bridges, and using more materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

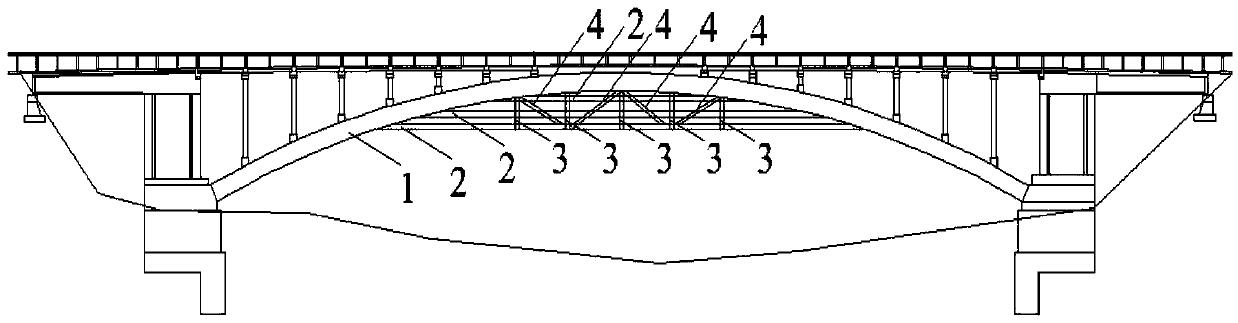

[0020] The arch bridge in Example 1 is an overhead arch bridge with a span of 100.00m, a reinforced concrete box-shaped arch rib, a net rise height of 11.10m, and a rise-span ratio of 1 / 9. The foundation, the abutment on both sides is the embedded abutment of mortar rubble, the enlarged foundation of open cut, and the longitudinal beam (2), the column (3) and the diagonal rod (4) are added under the arch rib (1), and the arch rib (1 ) bending stiffness and compressive stiffness are 7.23×1011kN·m2 and 1.24×108kN·m respectively; horizontal steel truss longitudinal beams (2) with lengths of 20m, 35m and 50m are erected respectively, and their bending stiffness and compressive stiffness are both They are 3.62×1011kN m2 and 1.24×108kN m2 respectively, and the longitudinal beam (2) and the arch rib are fixed; five vertical steel bars with a compressive stiffness of 3.10×107kN m are installed under the arch rib (1). The truss column (3), the top of the column (3) is hinged to the arc...

Embodiment 2

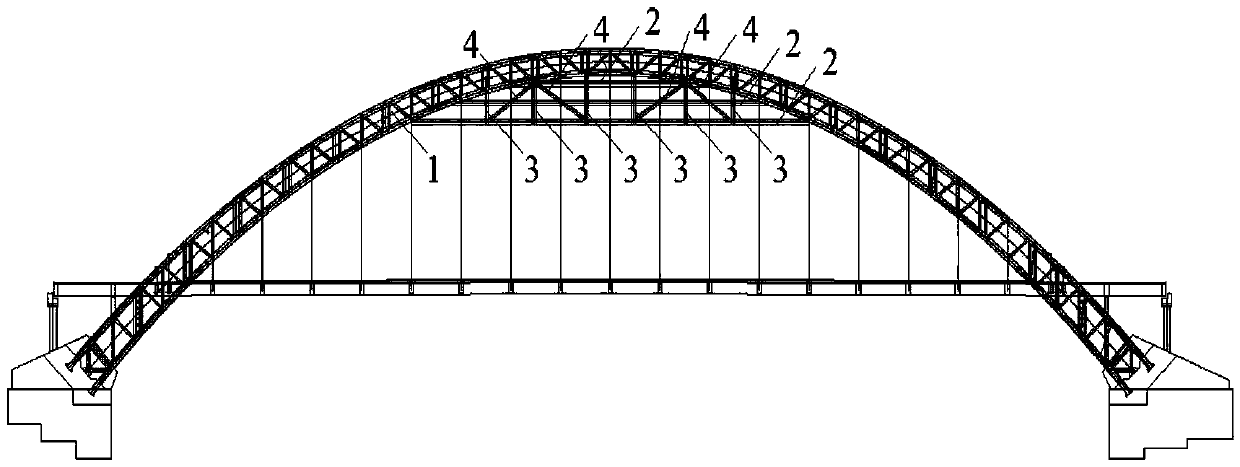

[0022] The arch bridge in Example 2 is an under-supported arch bridge with a span of 100.00m reinforced concrete box-shaped arch ribs, a net rise height of 11.10m, and a rise-span ratio of 1 / 9. A longitudinal beam (2) is added below the arch rib (1) , columns (3) and diagonal rods (4), arch ribs (1) have bending stiffness and compressive stiffness of 7.23×1011kN m2 and 1.24×108kN m2 respectively; Steel truss longitudinal beam (2), its flexural rigidity and compressive rigidity are 5.10×1011kN m2, 1.24×108kN m2 respectively, longitudinal beam (2) and arch rib are all fixed; arch rib (1) below Set up 6 vertical steel truss columns (3) with a compressive stiffness of 4.95×107kN·m, the top of the columns (3) is hinged to the arch rib (1), and the bottom is fixed to the 50m longitudinal beam (2). The joints are respectively 15m, 19m, 23m, 27m, 31m and 35m, and the column body (3) is fixedly connected with the other two longitudinal beams; a diagonal web bar (4) is set between two a...

Embodiment 3

[0024] The arch bridge in Example 3 is an overhead arch bridge with a span of 100.00m, a reinforced concrete box-shaped arch rib, a net rise height of 11.10m, and a rise-span ratio of 1 / 9. The foundation, the abutment on both sides is the embedded abutment of mortar rubble, the enlarged foundation of open cut, and the longitudinal beam (2), the column (3) and the diagonal rod (4) are added under the arch rib (1), and the arch rib (1 ) The bending stiffness and compressive stiffness are 7.23×1011kN m2 and 1.24×108kN m respectively; the erection length is 45m, and the bending stiffness and compressive stiffness are 7.23×1011kN m2 and 1.24×108kN m2 respectively The truss is used as the longitudinal beam (2), and the longitudinal beam (2) is fixedly connected to the arch rib; four vertical steel truss columns (3) with a compressive stiffness of 6.20×107kN·m are arranged under the arch rib (1), The top of the column (3) is hinged to the arch rib (1), and the bottom end is fixed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com