Method for producing yarn used for sponge towels

A production method and technology for towel, applied in the direction of yarn, textiles and papermaking, can solve the problems of no fluffy feeling, hard hand feeling, hygroscopicity and quick-drying need to be further improved, etc., to achieve good hygroscopicity, less hairiness and strength. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of production method of sponge towel yarn

[0031] Include the following steps:

[0032] 1. Raw material selection

[0033] ① Cotton, machine-harvested Xinjiang cotton, color characteristic grade 31, length 28.00mm, micronaire value 4.66, fineness 5413 metric, single fiber breaking strength 29.52cN / tex, uniformity 81.81%, short fiber 11.3%, moisture regain 6.93%, containing 1.7% impurities;

[0034] ②Water-soluble vinylon, linear density 1.33dtex, length 38.00mm, dry breaking strength 5.14cN / tex, defect: 0.65mg / 100g, moisture regain 3.99%, dissolution temperature in water 85℃.

[0035] 2. Cotton raw material yarn making

[0036] (1) Pre-treatment of cotton raw materials

[0037] Cotton raw materials enter the drawing process through the opening and cleaning process, carding process, and combing process. According to the combed sliver fiber hook and drafting theory, it is based on the principle of improving evenness and strength.

[0038] (2) Dra...

Embodiment 2

[0076] Example 2 After the sponge towel is made into a towel from yarn, the fiber removal test is carried out

[0077] After de-dimensionalizing, the remaining cotton fiber single yarn changes back to the original "S" twist direction, and the remaining twist is the twist difference between the single yarn and the two-for-one twist;

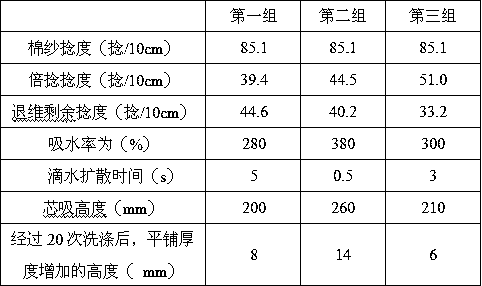

[0078] Adjust the size of the friction surface between the dragon belt and each spindle disc, the distance between the cradle and the roller head, and reduce the difference in twist between the spindles. Two-for-one twisting designs three different twists for experiments. After the towel is made, the remaining twist and other indicators of the towel are tested as follows:

[0079]

[0080] The finished product quality feel and hygroscopicity of the second group, thickness increase after washing and other indexes are all better than the first group and the third group, so the two-for-one twist degree of the second group is 44.5 twists / 10cm is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com