Preparation method of protective coating based on working surface of mould matrix

A technology for working surface and protective coating, applied in the field of preparation of protective coating, can solve the problems of low bonding strength, etc., and achieve the effects of good wear resistance and lubricity, simple and convenient operation, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

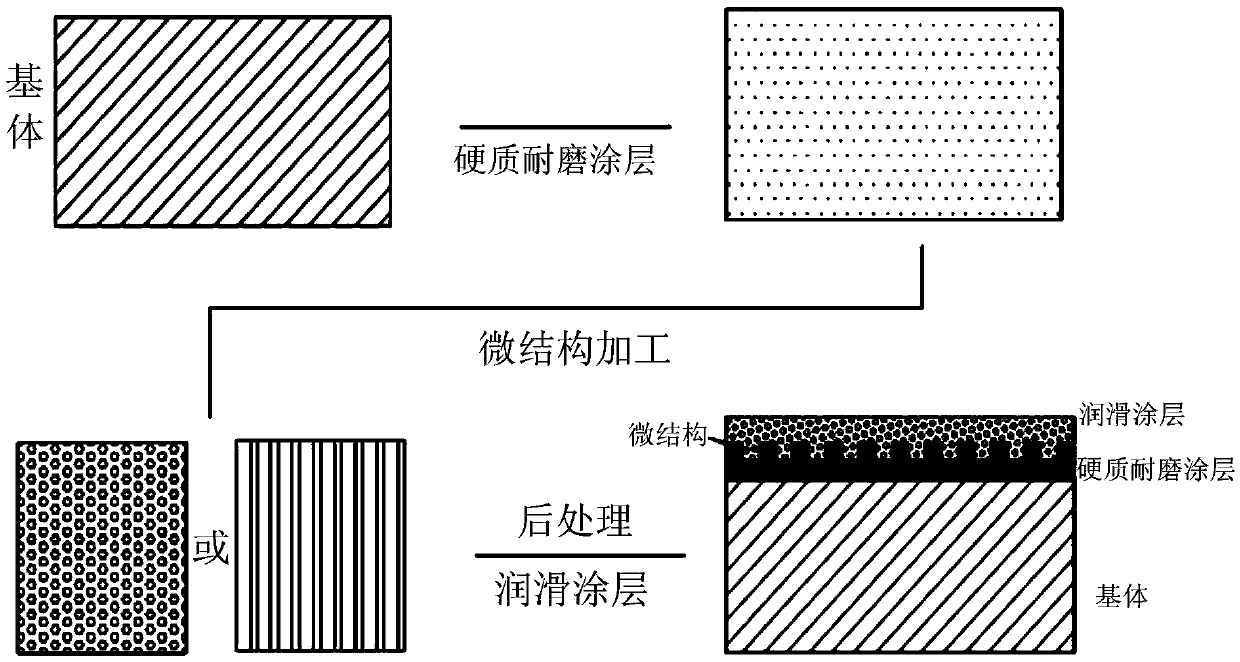

[0035] The invention provides a protective coating based on the working surface of the mold substrate, the preparation process of the coating is as follows figure 1 As shown, it includes the following steps:

[0036] 1) Cleaning of parts

[0037] Put the substrate to be processed in acetone solution, and then put it into an ultrasonic cleaning test machine for ultrasonic cleaning. The cleaning time is 30 minutes; Ultrasonic cleaning, the cleaning time is 30min, and finally the substrate is dried with a hair dryer.

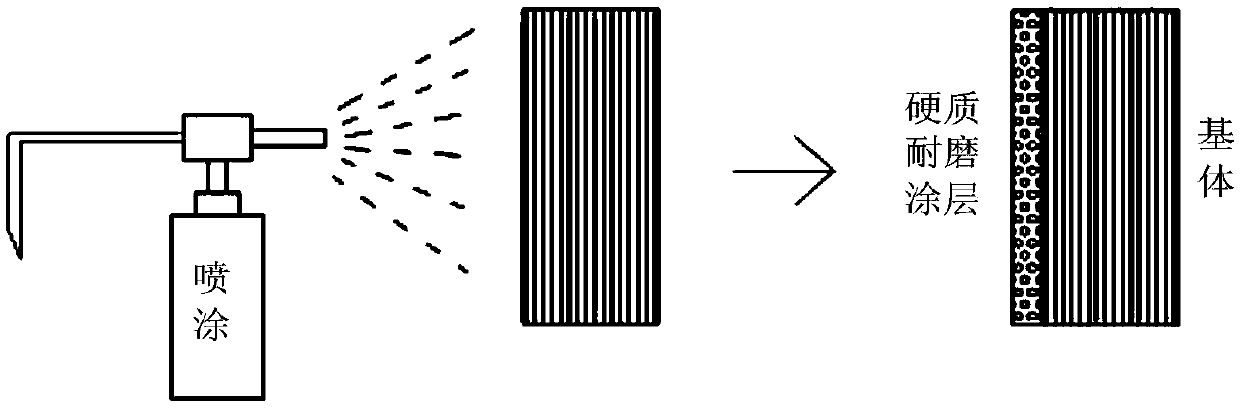

[0038] 2) Preparation of hard wear-resistant coating

[0039] Put the base material in the spraying workshop, fill the spraying filling port with an appropriate amount of SiC powder, and use low-temperature plasma spraying technology for spraying (such as figure 2 Shown), during the spraying process, a hard wear-resistant coating with a thickness of 200 μm was prepared on the working surface of the substrate by adjusting the spraying process parameters.

[004...

Embodiment 2

[0047] This embodiment provides a protective coating based on the working surface of the mold substrate, the preparation process of the layer is as follows figure 1 As shown, it includes the following steps:

[0048] 1) Cleaning of parts

[0049] Put the substrate to be processed in acetone solution, and then put it into an ultrasonic cleaning test machine for ultrasonic cleaning. The cleaning time is 30 minutes; Ultrasonic cleaning, the cleaning time is 30min, and finally the substrate is dried with a hair dryer.

[0050] 2) Preparation of hard wear-resistant coating

[0051] Put the base material in the spraying workshop, fill the spray filler port with an appropriate amount of alumina powder, and use low-temperature plasma spraying technology for spraying. During the spraying process, adjust the spraying process parameters to obtain a hard and durable surface with a thickness of 200 μm. Grinding coating.

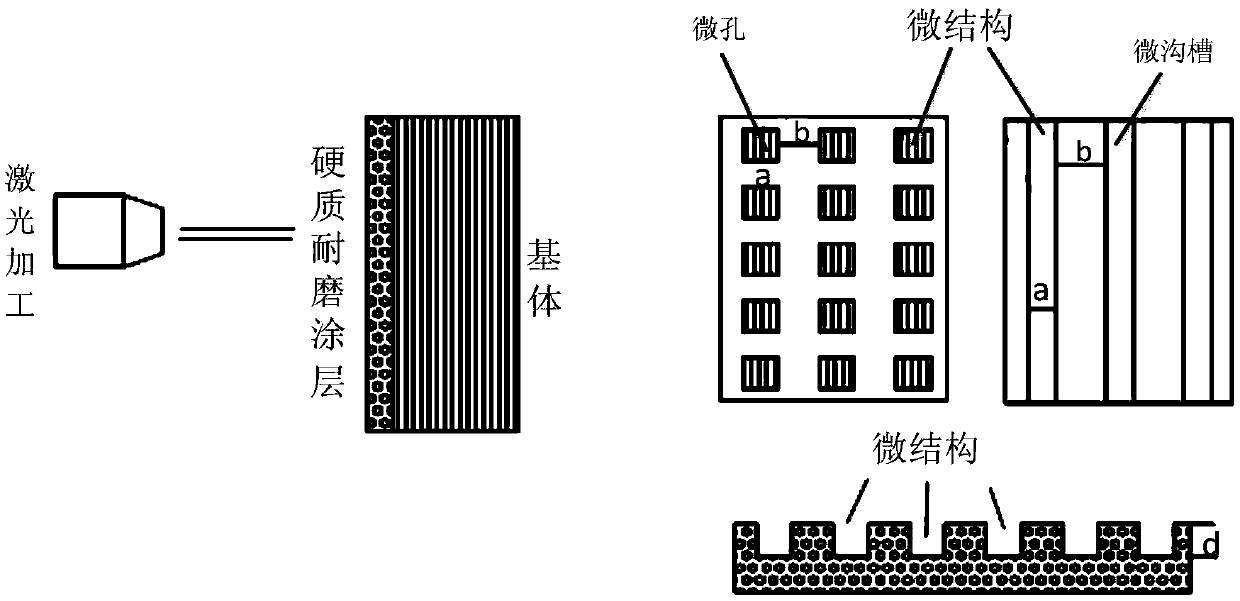

[0052] 3) Preparation of microstructure

[0053] Laser drilling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com