Preparation method for special rutile titanium dioxide used for papermaking

A rutile type, titanium dioxide technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve the problems of titanium dioxide dispersion, residence rate, and light resistance at the same time, to avoid crystal lattice Effects of defects, improvement of dispersibility, and stabilization of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

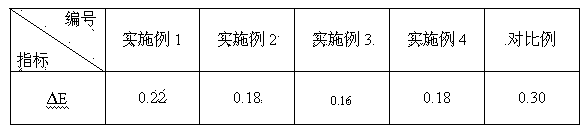

Examples

Embodiment 1

[0025] Sand mill the kiln products of the calcined qualified sulfuric acid titanium dioxide, and then grind the particle size D 50 The qualified slurry is introduced into the coating tank, and the concentration of the slurry is controlled to be 250g / L (based on TiO 2 At the same time, the temperature was raised to 70°C; the pH of the slurry was adjusted to 2.0 with dilute sulfuric acid; then 1.0% phosphoric acid solution was added and homogenized for 20 minutes; then sodium metaaluminate solution was added to adjust the pH to 6.0 and kept at this pH for aging 60min; finally add 5.0% (as Al 2 o 3 Calculate) sodium metaaluminate solution, and add dilute sulfuric acid solution at the same time to keep the pH of the slurry at 5.0. After the addition, mature for 2 hours; after the coating is completed, perform three washings, flash evaporation, and steam powder. Add 0.5% sodium nitrate solution to steam powder to obtain finished titanium dioxide.

Embodiment 2

[0027] Sand mill the kiln products of the calcined qualified sulfuric acid titanium dioxide, and then grind the particle size D 50 The qualified slurry is introduced into the coating tank, and the concentration of the slurry is controlled to be 270g / L (based on TiO 2 At the same time, the temperature was raised to 70°C; the pH of the slurry was adjusted to 2.0 with dilute sulfuric acid; then 2.0% phosphoric acid solution was added and homogenized for 20 minutes; then sodium metaaluminate solution was added to adjust the pH to 6.5, and the pH was maintained at this pH for aging 60min; finally add 3.0% (as Al 2 o 3 Calculate) sodium metaaluminate solution, and add dilute sulfuric acid solution at the same time to keep the pH of the slurry at 5.5. After the addition, mature for 2 hours; after the coating is completed, perform three washings, flash evaporation, and steam powder. Add 2.0% sodium nitrate solution to steam powder to obtain finished titanium dioxide.

Embodiment 3

[0029] Sand mill the kiln products of the calcined qualified sulfuric acid titanium dioxide, and then grind the particle size D 50 The qualified slurry is introduced into the coating tank, and the concentration of the slurry is controlled to be 300g / L (based on TiO 2 At the same time, the temperature was raised to 70°C; the pH of the slurry was adjusted to 2.5 with dilute sulfuric acid; then 3.5% phosphoric acid solution was added and homogenized for 20 minutes; then sodium metaaluminate solution was added to adjust the pH to 7.0 and kept at this pH for aging 60min; finally add 2.0% (as Al 2 o 3 Calculate) sodium metaaluminate solution, and add dilute sulfuric acid solution at the same time to keep the pH of the slurry at 6.0. After the addition, mature for 2 hours; after the coating is completed, perform three washings, flash evaporation, and steam powder. Add 1.0% potassium nitrate solution to steam powder to obtain finished titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com