Self-repairing extrusion-grade polypropylene composite material and preparation method thereof

A composite material and extrusion-grade technology, which is applied in the preparation of self-repairable extrusion-grade polypropylene composite materials, and in the field of self-repairable extrusion-grade polypropylene composite materials, can solve the problem of easy scratches on the surface of extrusion-grade automotive products And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

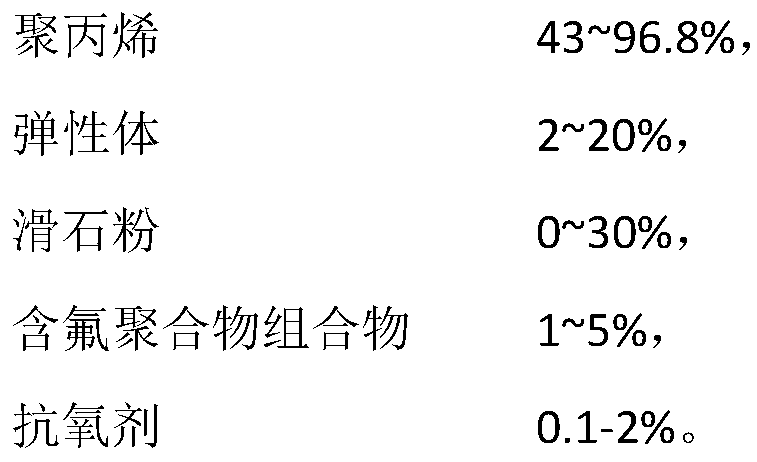

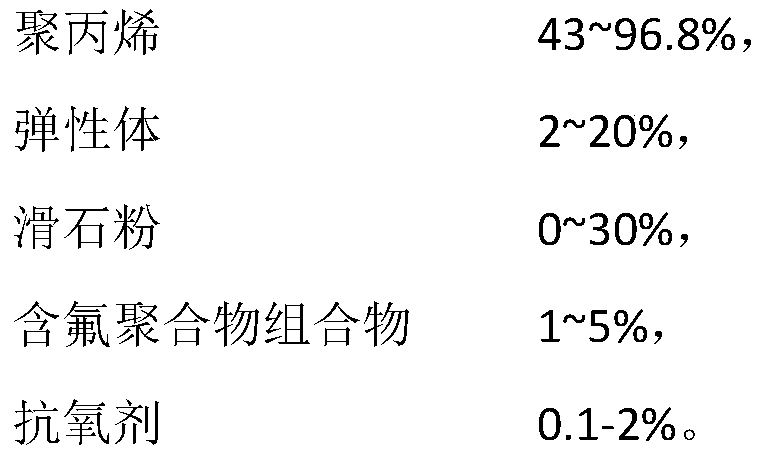

Method used

Image

Examples

Embodiment 1

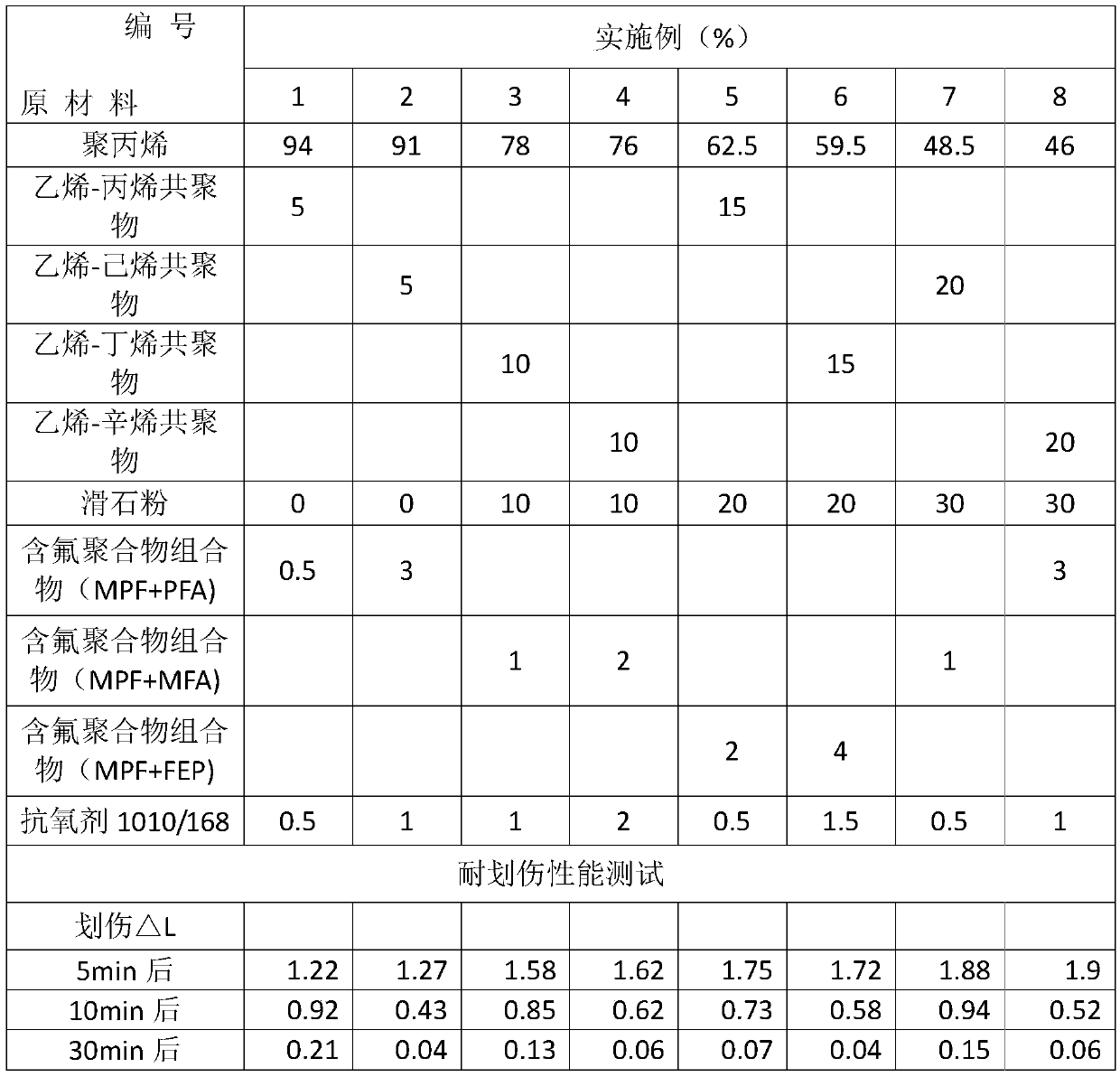

[0024] Take the components shown in Table 1 by weight percentage: polypropylene, elastomer (ethylene-propylene copolymer), talcum powder, fluoropolymer composition (polytetrafluoroethylene+perfluoropropylene vinyl ether PFA), Antioxidant. Mix the polypropylene, elastomer, and fluoropolymer composition in a high mixer for 3 minutes, then add talcum powder and antioxidant, and mix for another 2 minutes. The speed of the high mixer is 1500 rpm to obtain a premixed The premixed material is melted and extruded by a twin-screw extruder, and vacuum granulated to obtain a self-repairing extrusion-grade polypropylene composite material. The data after scratching and self-repairing of the scratches were measured, and the specific data are listed in Table 1.

Embodiment 2

[0026] Take the components shown in Table 1 by weight percentage: polypropylene, elastomer (ethylene-hexene copolymer), talcum powder, fluoropolymer composition (polytetrafluoroethylene+perfluoropropylene vinyl ether PFA) , Antioxidant. The preparation method is the same as in Example 1, and the performance test data are listed in Table 1.

Embodiment 3

[0028] Take the components shown in Table 1 by weight percentage: polypropylene, elastomer (ethylene-butylene copolymer), talcum powder, fluoropolymer composition (polytetrafluoroethylene+perfluoromethyl vinyl ether MFA ), antioxidants. The preparation method is the same as in Example 1, and the performance test data are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com