Anionic high-polymer flocculant and preparation method thereof

An anionic polymer and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor salt tolerance and limitations, and achieve the effect of good salt tolerance, wide pH range, and enlarged size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

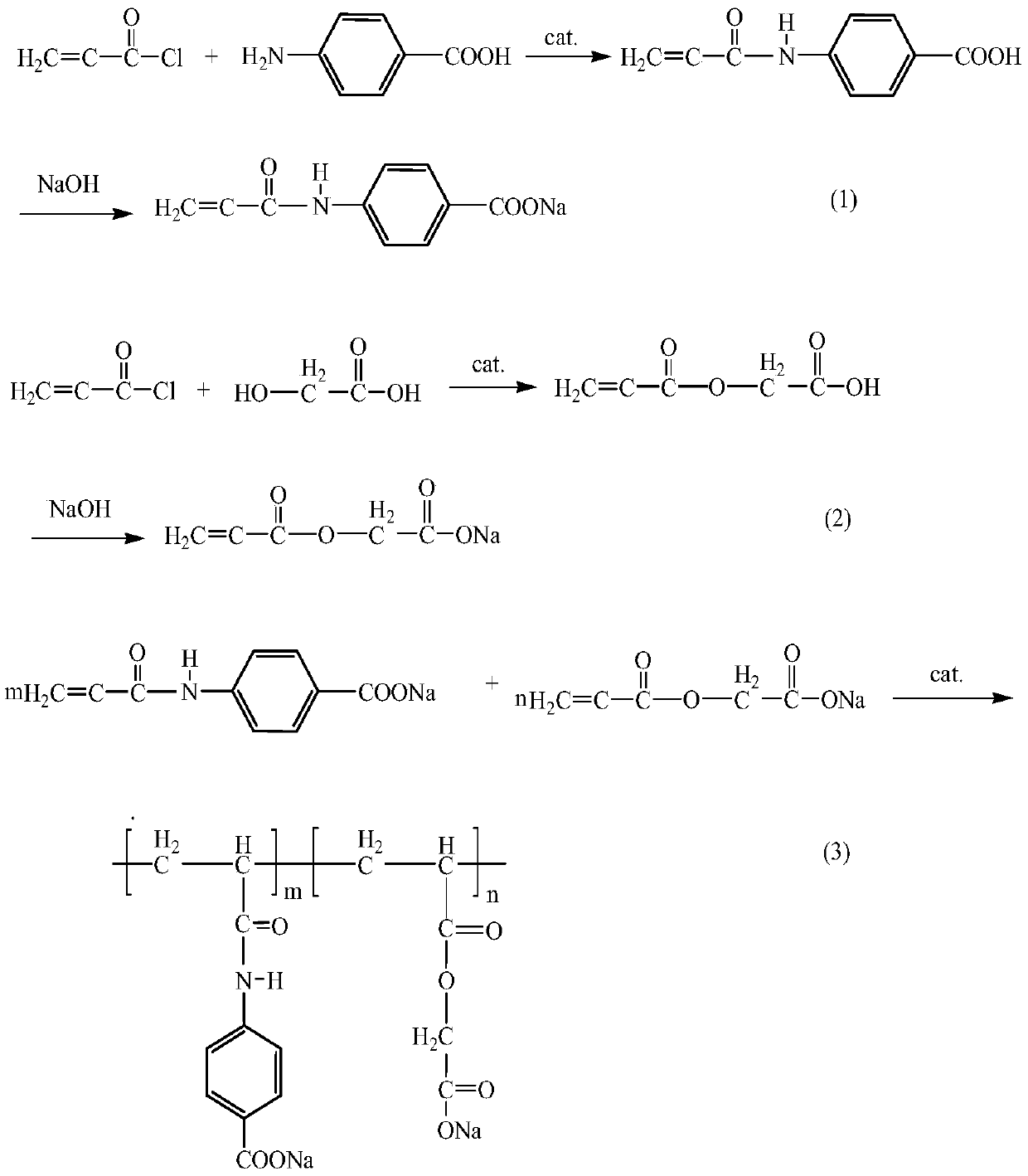

Method used

Image

Examples

Embodiment 1

[0044] (1) Add p-aminobenzoic acid to the solvent ethyl acetate and add acid-binding agent triethylamine, stir to fully dissolve p-aminobenzoic acid and heat up to 30°C, then slowly add acryloyl chloride dropwise for 15 minutes After the dropwise addition, the temperature was raised to 45°C, condensed and refluxed for constant temperature reaction for 2 hours, and a mixture of p-acrylamide benzoic acid and triethylamine hydrochloride was obtained; wherein, the mass ratio of p-aminobenzoic acid, acryloyl chloride and triethylamine It is 1:1:0.5.

[0045] (2) The mixture of p-acrylamide benzoic acid and triethylamine hydrochloride prepared in step (1) was washed twice with deionized water at room temperature, and the crude product of p-acrylamide benzoic acid was obtained by suction filtration, which was purely crystallized with ethanol The pure product of p-acrylamide benzoic acid was obtained.

[0046] (3) obtain the aqueous solution of sodium p-acrylamide benzoate with the p...

Embodiment 2

[0052] (1) Add p-aminobenzoic acid to the solvent ethyl acetate and add the acid-binding agent triethylamine, stir to fully dissolve the p-aminobenzoic acid and raise the temperature to 40°C, and slowly add acryloyl chloride dropwise for 25 minutes After the dropwise addition, the temperature was raised to 45°C, condensed and refluxed for constant temperature reaction for 1.5h, and a mixture of p-acrylamide benzoic acid and triethylamine hydrochloride was obtained; wherein, the amount of p-aminobenzoic acid, acryloyl chloride and triethylamine The ratio is 1:1.2:0.7.

[0053] (2) The mixture of p-acrylamide benzoic acid and triethylamine hydrochloride prepared in step (1) was washed twice with deionized water at room temperature, and the crude product of p-acrylamide benzoic acid was obtained by suction filtration, which was purely crystallized with ethanol The pure product of p-acrylamide benzoic acid was obtained.

[0054] (3) obtain the aqueous solution of sodium p-acrylam...

Embodiment 3

[0060] (1) Add p-aminobenzoic acid to the solvent ethyl acetate and add acid-binding agent sodium hydroxide, stir to fully dissolve p-aminobenzoic acid and heat up to 45°C, and slowly add acryloyl chloride dropwise for 30 minutes , after the dropwise addition, the temperature was raised to 50°C, condensed and refluxed for constant temperature reaction for 1 hour, and a mixture of p-acrylamide benzoic acid and triethylamine hydrochloride was obtained; wherein, the mass ratio of p-aminobenzoic acid, acryloyl chloride and triethylamine It is 1:1.2:0.9.

[0061] (2) The mixture of p-acrylamide benzoic acid and triethylamine hydrochloride prepared in step (1) was washed 3 times with deionized water at room temperature, and the crude product of p-acrylamide benzoic acid was obtained by suction filtration, which was purely crystallized with ethanol The pure product of p-acrylamide benzoic acid was obtained.

[0062] (3) obtain the aqueous solution of sodium p-acrylamide benzoate wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com