Purified water production technology

A production process and pure water technology, applied in the field of water purification, can solve problems such as health threats, achieve less energy loss, low power consumption, and beneficial effects on health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

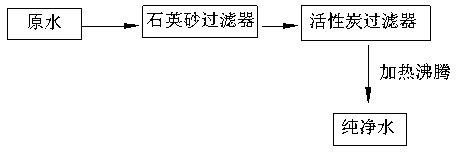

[0025] Such as figure 2 as shown,

[0026] Pure water production technique of the present invention, concrete steps are:

[0027] 1) The raw water is filtered through a quartz sand filter to obtain primary purified water;

[0028] 2) The primary purified water is filtered through an activated carbon filter to obtain secondary purified water;

[0029] 3) The secondary purified water is heated to boiling by 2000MHz microwave, and the boiling time is 7 minutes;

[0030] 4) cooling;

[0031] 5) Aseptic filling.

Embodiment 2

[0033] Pure water production technique of the present invention, concrete steps are:

[0034] 1) The raw water is filtered through a quartz sand filter to obtain primary purified water;

[0035] 2) The primary purified water is filtered through an activated carbon filter to obtain secondary purified water;

[0036] 3) The secondary purified water is heated to boiling by 1800MHz microwave, and the boiling time is 8 minutes;

[0037] 4) cooling;

[0038] 5) Aseptic filling.

Embodiment 3

[0040] Pure water production technique of the present invention, concrete steps are:

[0041] 1) The raw water is filtered through a quartz sand filter to obtain primary purified water;

[0042] 2) The primary purified water is filtered through an activated carbon filter to obtain secondary purified water;

[0043] 3) The secondary purified water is heated to boiling by 1500MHz microwave, and the boiling time is 10 minutes;

[0044] 4) cooling;

[0045] 5) Aseptic filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com