A bush pressing mechanism

A technology of pressing mechanism and bushing, applied in the field of pressing machine, can solve the problems of inaccurate pressing position of bushing, reduce production efficiency, low bearing pressure, etc., to improve product qualification rate, simple structure, and increase bearing pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

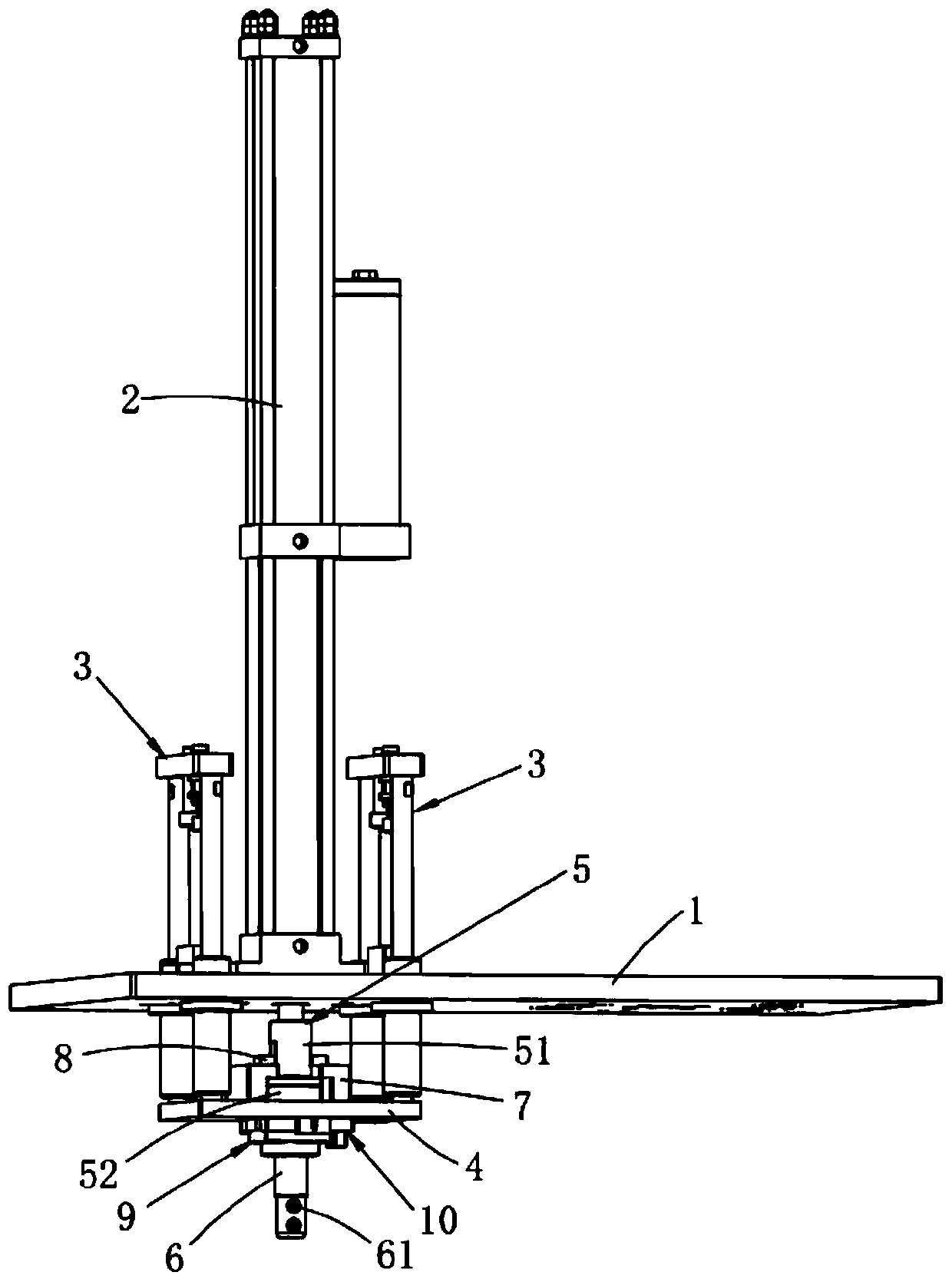

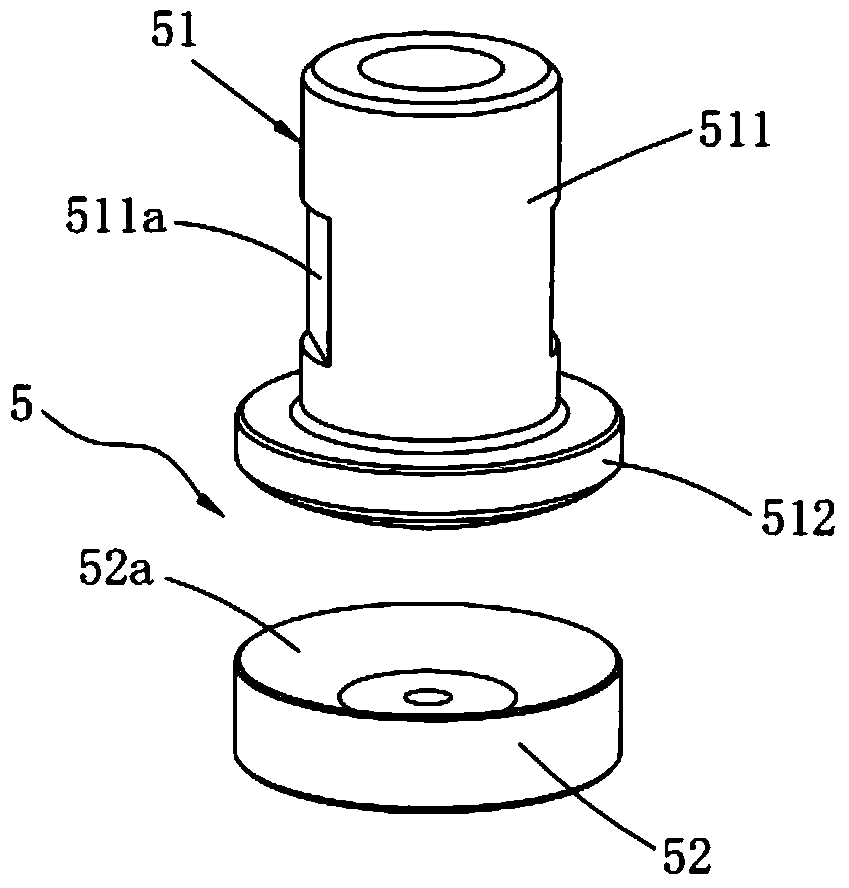

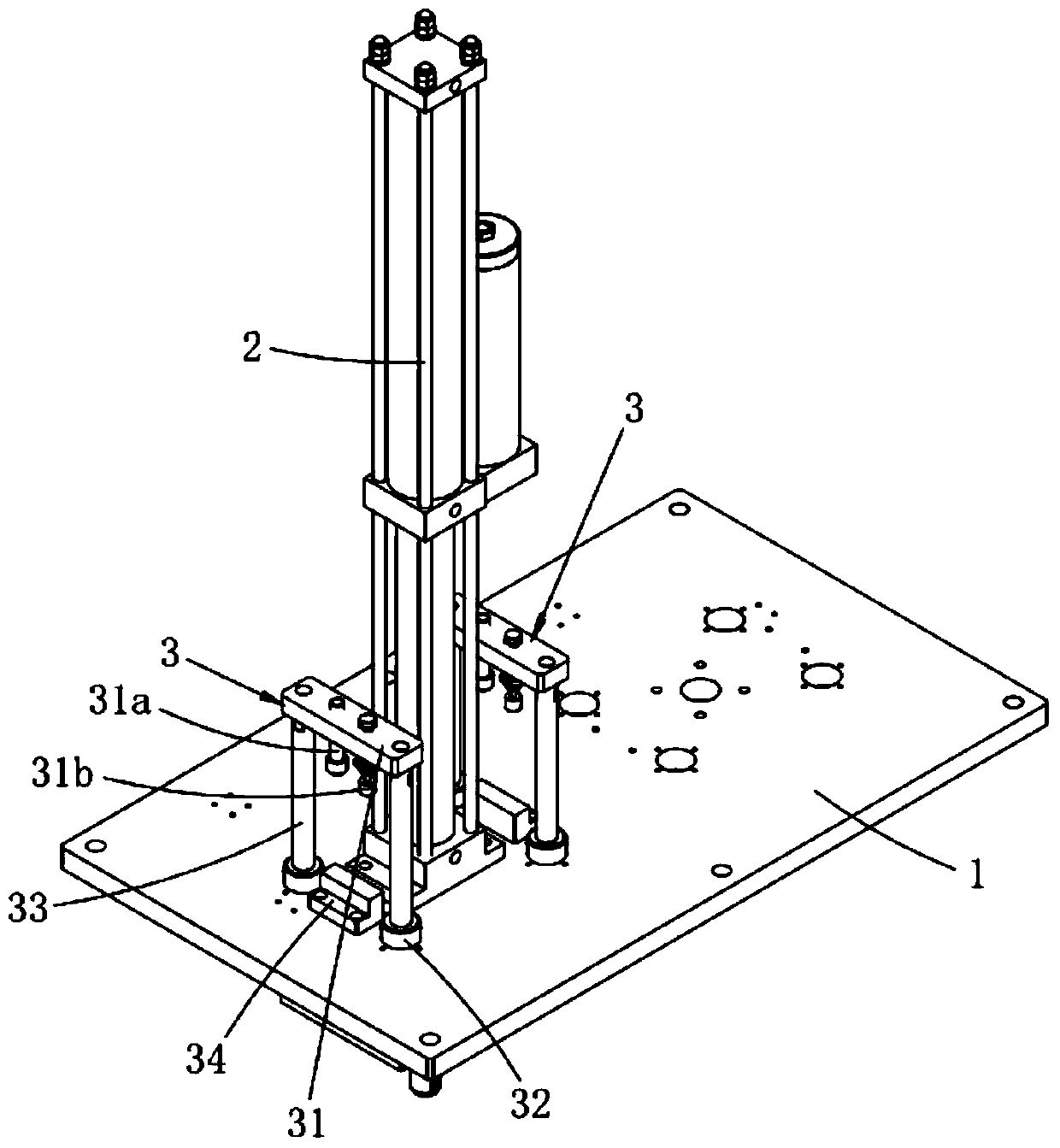

[0029] like figure 1 and figure 2 As shown, the present invention provides a bush pressing mechanism, including a base plate 1, a cylinder 2, a guide limit mechanism 3, a pressure head mounting plate 4, a cylinder joint 5 and a pressure head 6, and the cylinder 2 is installed on the base plate 1 The two sides of the cylinder 2 are oppositely provided with a guide limit mechanism 3, the end of the guide limit mechanism 3 is fixed with a pressure head mounting plate 4, and the pressure head mounting plate 4 is located below the bottom plate 1; the cylinder joint 5 includes an upper joint 51 and a lower joint 52, the upper joint 51 is installed on the piston rod of the cylinder 2, the lower joint 52 is arranged on the upper part of the pressure head mounting plate 4, and the upper joint 51 is provided with a cylindrical part 511 and a circular arc from top to bottom. Boss 512, the upper end surface of the lower joint 52 is processed with an arc groove 52a matching the arc boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com