A method of milling barrel material into arc plate

A technology of milling processing and barrel materials, which is applied in the direction of metal processing equipment, metal processing machinery parts, milling machine equipment, etc., can solve the problems of easy deformation of barrel materials, difficult clamping of barrel materials, and low production efficiency, so as to improve processing efficiency, Solve instability and ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

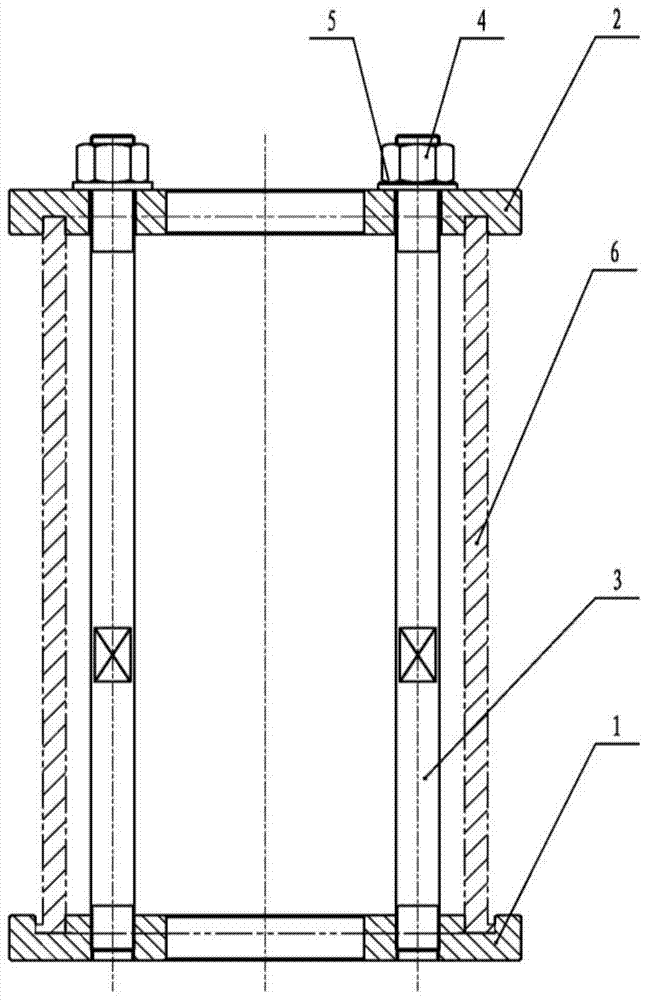

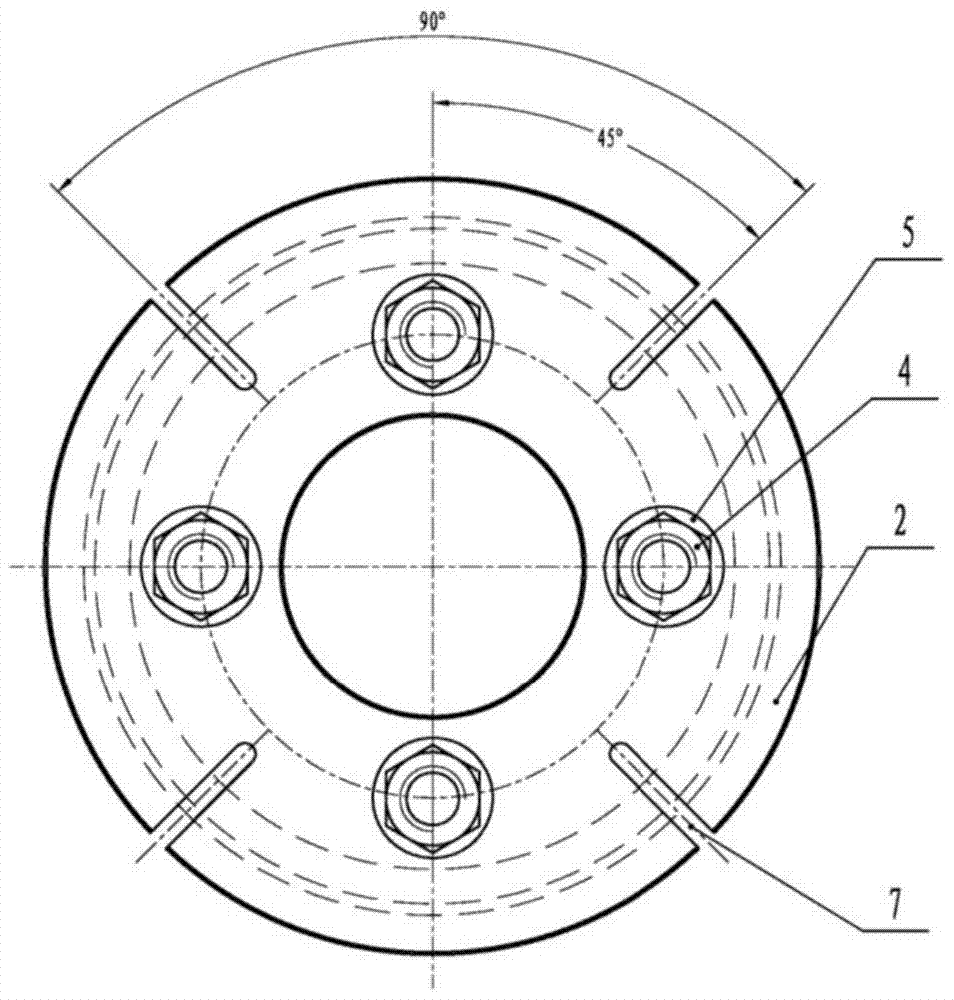

[0020] refer to figure 1 , figure 2 , image 3 , the present invention is processed into the method for arc plate by barrel material milling, relies on a set of fixed tooling, and the main part of this cover fixed tooling is base plate 1 and pressure plate 2, has a plurality of threaded holes concentrically on the base plate 1 (all threaded holes surround form a circle), the same number of through holes are opened at the corresponding positions of the pressure plate 2 and the bottom plate 1 in the axial direction (all the through holes form a circle), and the pressure plate 1 and the pressure plate 2 are fixedly connected by a plurality of screw rods 3;

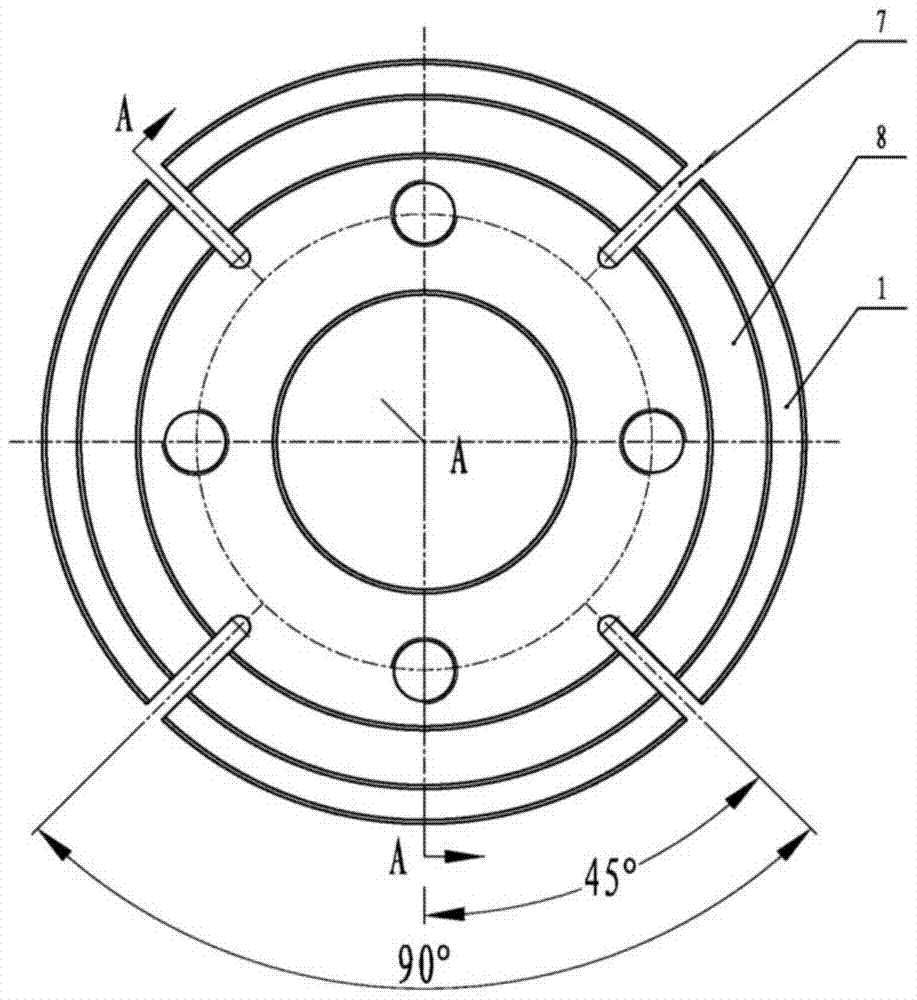

[0021] refer to Figure 4 with Image 6 , the inner end surface of the bottom plate 1 and the inner end surface of the pressure plate 2 are provided with an annular groove 8 of the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com