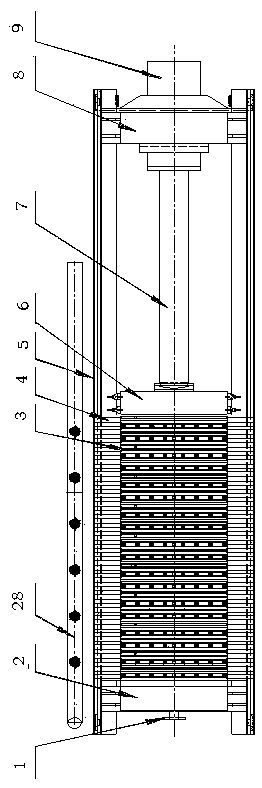

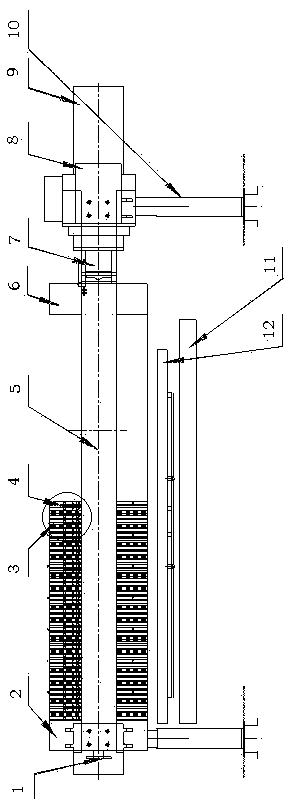

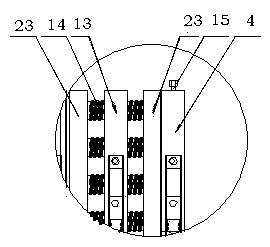

Titanium white gypsum suspension solid-liquid separation and hot-pressing drying equipment and production process thereof

A technology of solid-liquid separation and drying equipment, applied in the field of titanium dioxide gypsum suspension solid-liquid separation and titanium white gypsum deep dehydration, which can solve the problems of increasing drying cost and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The titanium dioxide gypsum suspension hydraulic filtration-hot press dehydration system and process of the present invention are used to process titanium gypsum data as follows:

[0040] Single processing capacity: equipped with a filtration area of 120m2 - hot pressing dehydration integrated equipment system and process The feeding time is 60 minutes, mechanical pressing is 10 minutes, then the drying plate is heated, hot pressing is 10 minutes, and the material is automatically unloaded In 5 minutes, about 8 tons of titanium gypsum can be obtained.

[0041] Heat source: low-pressure steam with a pressure of 1-2 kg.

[0042] Single cycle running time: 90 minutes.

[0043] Processing scale: 2050 cubic meters of suspension containing 5% titanium gypsum can be processed within 24 hours of operation, and about 128 tons of titanium gypsum can be processed.

[0044] Titanium gypsum free moisture: 21.6%.

Embodiment 2

[0046] The titanium dioxide gypsum suspension hydraulic filtration-hot press dehydration system and process of the present invention are used to process titanium gypsum data as follows:

[0047] Single processing capacity: Equipped with a filtration area of 120m2 pressure filter-hot press dehydration integrated equipment system and process The feeding time is 60 minutes, mechanical pressing is 10 minutes, and then the drying plate is heated, hot pressing for 15 minutes, automatic unloading The material time is 5 minutes, and about 8 tons of titanium gypsum can be obtained.

[0048] Heat source: low-pressure steam with a pressure of 1-2 kg.

[0049] Single run time: 95 minutes

[0050] Processing scale: 24 hours of operation time can process 1800m3 of 5% titanium gypsum suspension, and about 120 tons of titanium gypsum can be obtained.

[0051] Titanium gypsum free moisture: 15.6%.

Embodiment 3

[0053] The titanium dioxide gypsum suspension hydraulic filtration-hot press dehydration system and process of the present invention are used to process titanium gypsum data as follows:

[0054] Single processing capacity: The system and process equipped with a dehydration and drying integrated equipment with a filtration area of 120m2 have a feeding time of 60 minutes, mechanical pressing for 10 minutes, then heating the drying plate, hot pressing for 15 minutes, and automatic unloading time for 5 minutes Minutes, about 8 tons of titanium gypsum can be obtained.

[0055] Heat source: heat conduction oil at 110-130°C.

[0056] Single run time: 90 minutes

[0057] Processing scale: 1800m3 of suspension containing 5% titanium gypsum can be processed within 24 hours of operation time, and 120 tons of titanium gypsum can be obtained.

[0058] Titanium gypsum free moisture: 17.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com