Secondary counter-current extraction device and method

An extraction device and a technology for secondary extraction, applied in the field of secondary countercurrent extraction of reducing liquid, can solve the problems of wasting water resources, large steam consumption, increasing enterprise costs, etc., reducing steam consumption, reducing water consumption for extraction, and reducing enterprise costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

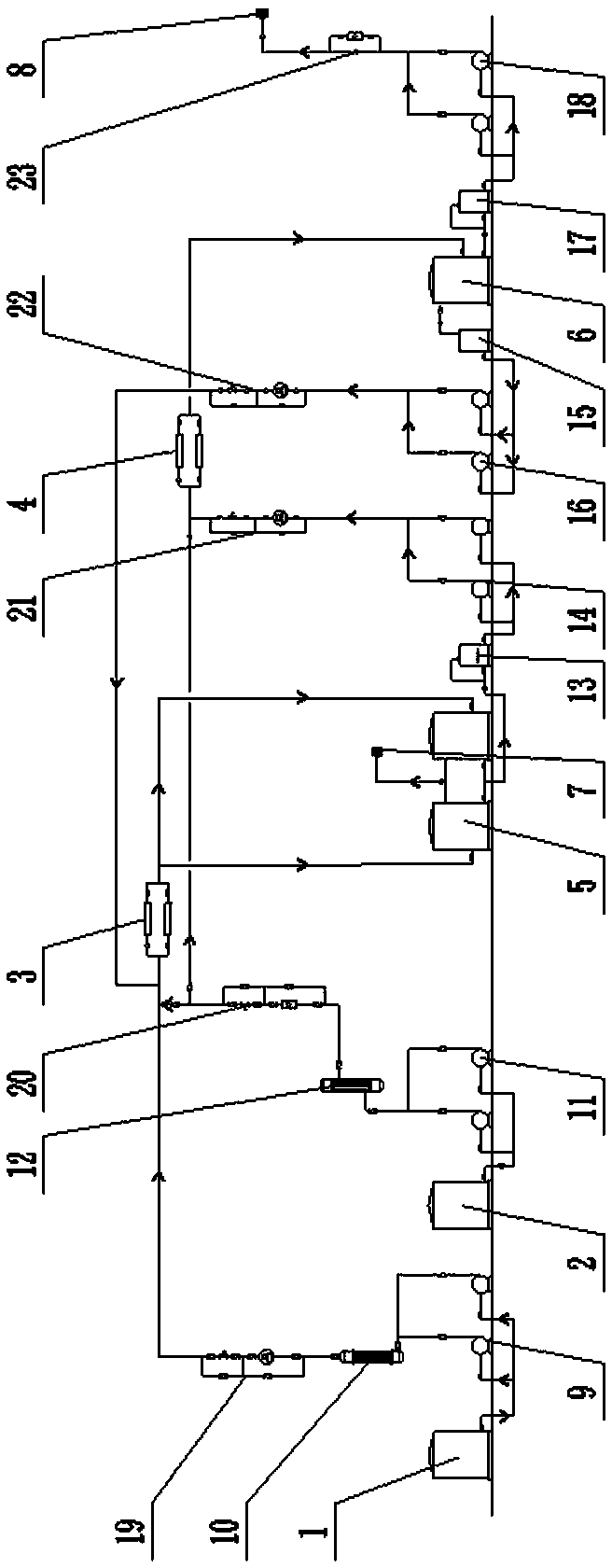

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the reducing solution in the reducing solution storage tank 1 reaches the reducing solution cooler 10 for cooling through the reducing solution delivery pump 9, and the soft water in the soft water storage tank 2 reaches the soft water cooler 12 for cooling through the soft water delivery pump 11, and the cooled reducing solution and soft water enter the primary mixer 3 through the reducing liquid flow control valve group 19 and the soft water flow control valve group 20 respectively for primary mixing, and the primary mixed liquid enters the primary extraction tank 5 for phase-separated extraction, and the primary extraction water is extracted from the top of the tank The phase enters the inorganic phase storage tank 7 for storage, and the primary extraction oil phase extracted from the bottom of the tank enters the primary extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com