An insulated and sealed electrode assembly

An electrode assembly, insulation and sealing technology, applied in the direction of fixed/insulated contact members, electrical components, circuits, etc., can solve the problems of inability to withstand high temperature, poor sealing effect, complex structure, etc., to ensure safety, ensure sealing, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

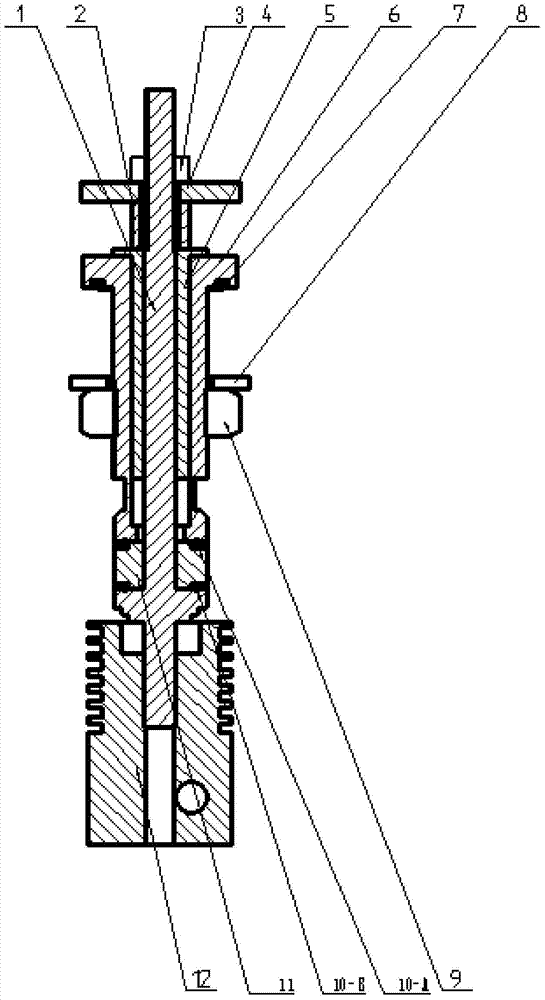

[0032] Such as figure 1 , figure 2 As shown, the present invention includes a copper rod 1, an upper sleeve 2, an upper fixing nut 3, an isolation washer 4, an inner sleeve 5, an outer sleeve 6, a base sealing ring 7, a fixing washer 8, a lower fixing nut 9 and a lower sleeve barrel 11;

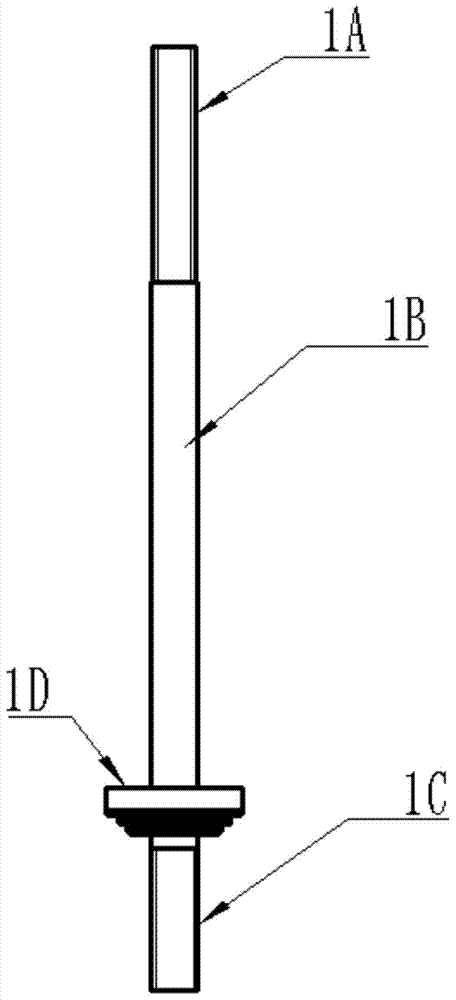

[0033] Such as image 3 As shown, the copper rod 1 is a round rod, the upper end 1A and the lower end 1C of the shaft 1B respectively have external threads, and the lower part of the shaft 1B has an integral annular boss 1D;

[0034] Such as Figure 4 As shown, the lower sleeve 11 is a cylinder made of insulating material, and the upper and lower end surfaces of the lower sleeve 11 respectively have annular upper grooves 11A and lower grooves 11B;

[0035] Such as Figure 5 As shown, the outer sleeve 6 is a hollow rotating body, its upper end forms an annular sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com