Perovskite solar cell module package structure and package method

A solar cell and packaging structure technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems affecting the performance of perovskite solar cells, water resistance cannot meet the requirements of perovskite solar cells, etc., and achieve good anti-ultraviolet aging , Guarantee long-term stable work and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

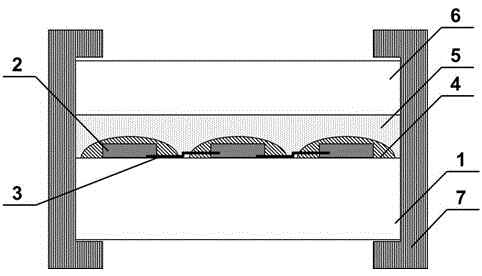

[0029] Such as figure 1 As shown, the perovskite solar cell packaging structure of the present invention is used to package several perovskite solar cells 2 into a photovoltaic module, and several perovskite solar cells 2 are laid flat without overlapping each other; The batteries 2 are connected in series through interconnecting conductive lines 3 to form several series groups, and the several series groups are connected in parallel, and then the positive pole and the negative pole are drawn out through confluence. The package structure includes: a back substrate 1, an encapsulant and a front glass 6. The encapsulant includes a solar cell encapsulant 4 for encapsulating a single solar cell and a component encapsulant 5 for encapsulating several solar cells together. The solar cell encapsulation The glue 4 at least partially covers the perovskite solar cell, the solar cell packaging glue 4 adopts colorless and transparent epoxy packaging glue, silicone packaging glue, polyuret...

Embodiment 2

[0031] Another aspect of the present invention provides a perovskite solar cell encapsulation method, comprising the steps of:

[0032] A. Provide multiple perovskite solar cells;

[0033] B. Arrange the perovskite solar cells in a flat arrangement, use conductive wires to connect the lower electrode and the upper electrode of the perovskite solar cells in series to form several series groups, and connect several series groups in parallel, and then lead out the positive and negative electrodes through confluence ;

[0034] C. In this embodiment, the solar cell encapsulation glue is colorless and transparent epoxy resin glue, and the epoxy resin glue is configured according to the ratio of A:B=2:1. The temperature is controlled at 80°C, and the curing time is 2 hours. Solar cell encapsulant;

[0035] D. Place the perovskite solar cell processed in step C on the back substrate, and make the light-receiving surface of the perovskite solar cell face up;

[0036] E. Cover the ba...

Embodiment 3

[0041] The difference between this embodiment and embodiment 2 is:

[0042] In step G, the temperature of the heating is 100°, and the heating time is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com