Two-dimensional rock sample seepage testing device

A rock sample and test device technology, which is applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem that the two-dimensional rock sample cannot be loaded with extrusion force and shear force and other problems, to achieve the effect of low cost, high control precision and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

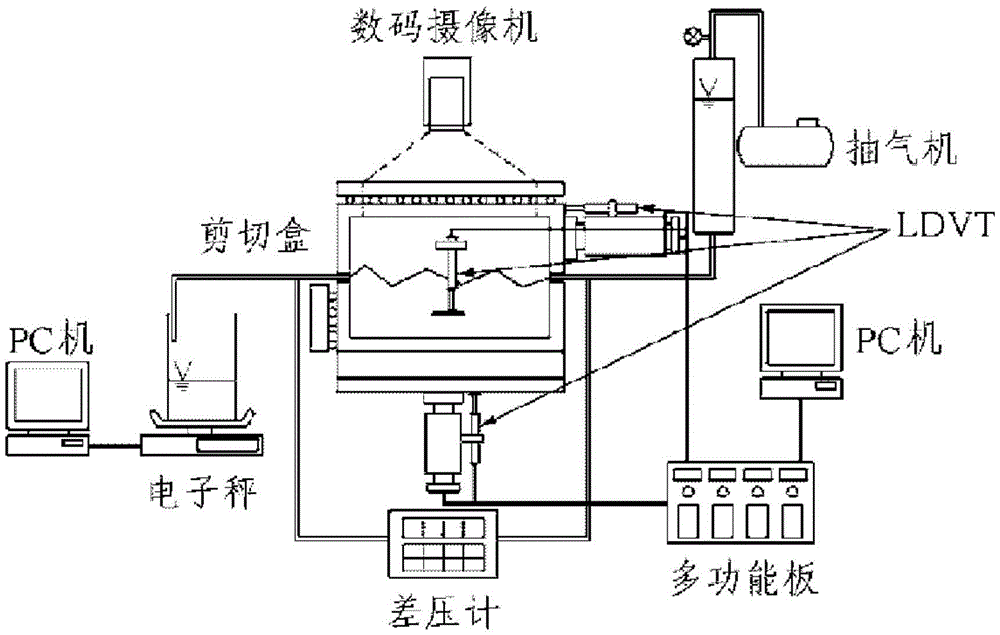

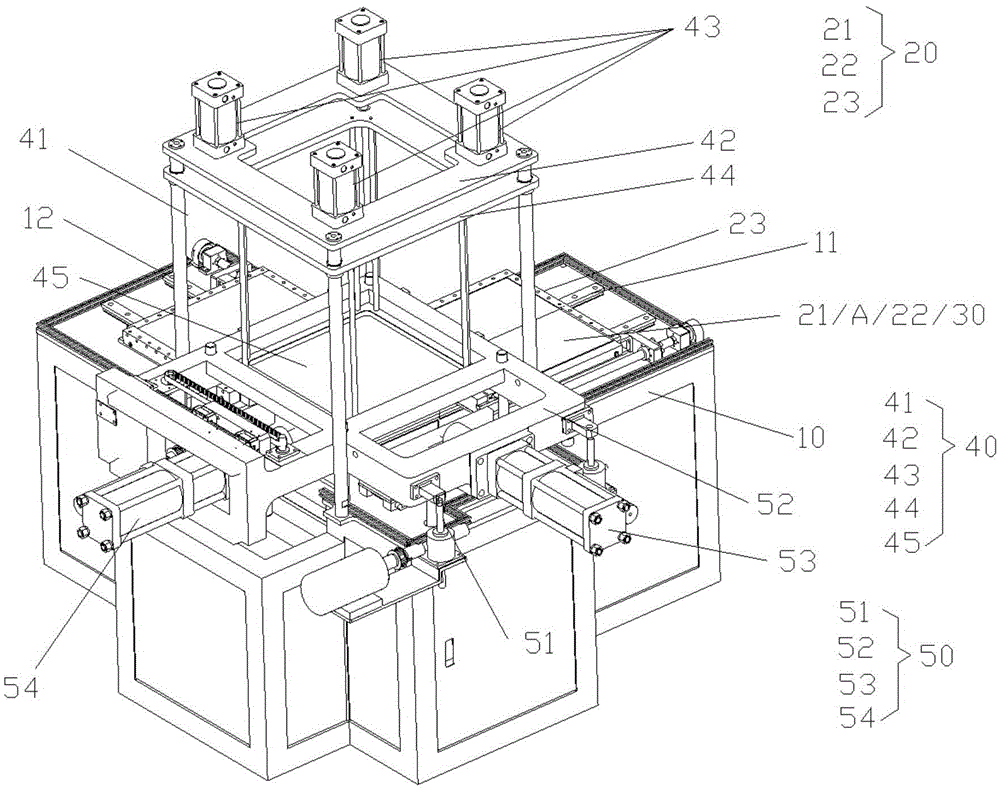

[0059] The present invention aims at the problem of high cost of the horizontal force loading mechanism in the rock sample seepage test device in the prior art, and provides a two-dimensional rock sample seepage test device, which can be applied to the joint action of the stress field and the water flow field in rock cracks Under the experimental study of the failure mechanism.

[0060] It should be noted that the horizontal force loading mechanism in the following embodiments is described as a part of the two-dimensional rock sample seepage test device. Of course, in other embodiments of the present invention, the horizontal force loading mechanism can also be used alone or as an accessory mechanism of other equipment.

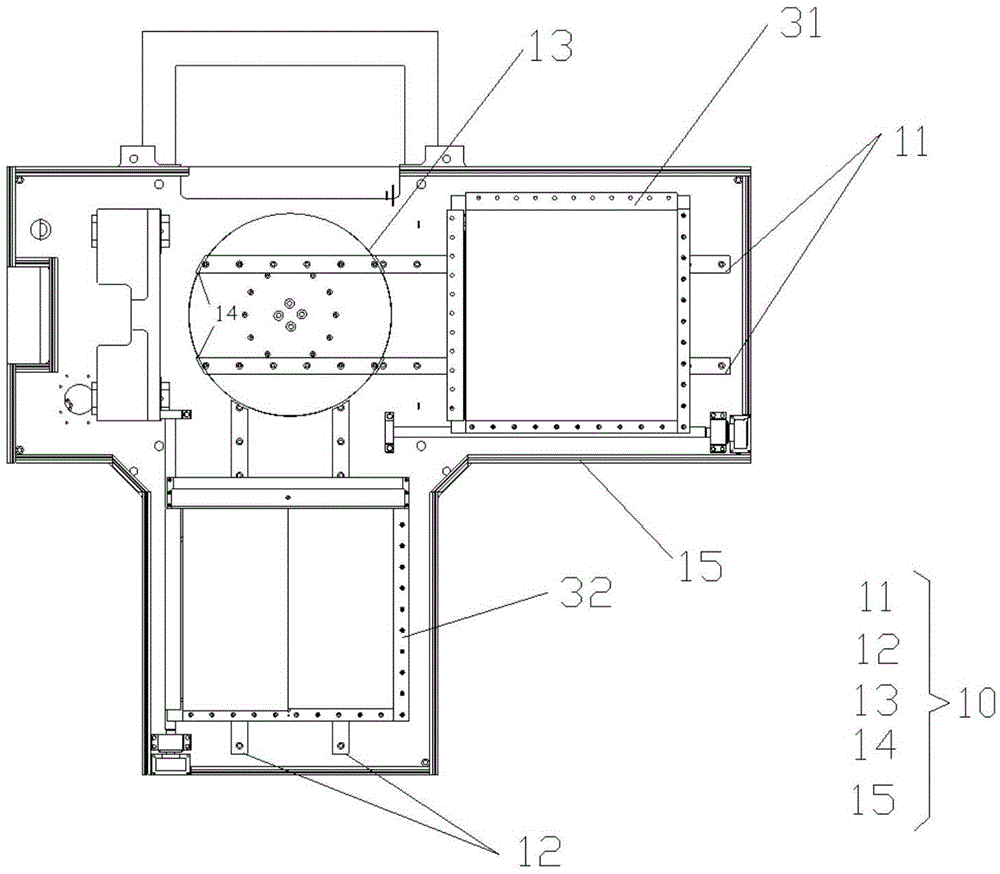

[0061] In an exemplary embodiment of the present invention, a two-dimensional rock sample seepage test device is provided. In this embodiment, the test object is a square bluestone slab A, the size of which is: length 500mm, width 500mm, thickness 10-20mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com