a brake disc

A technology of brake disc and disc body, applied in the direction of brake disc, etc., can solve the problems of low strength of the outer peripheral part of the brake disc body 1, unable to stop the radial growth of cracks, affecting the service life of the brake disc, etc. Better performance, better heat dissipation, longer residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

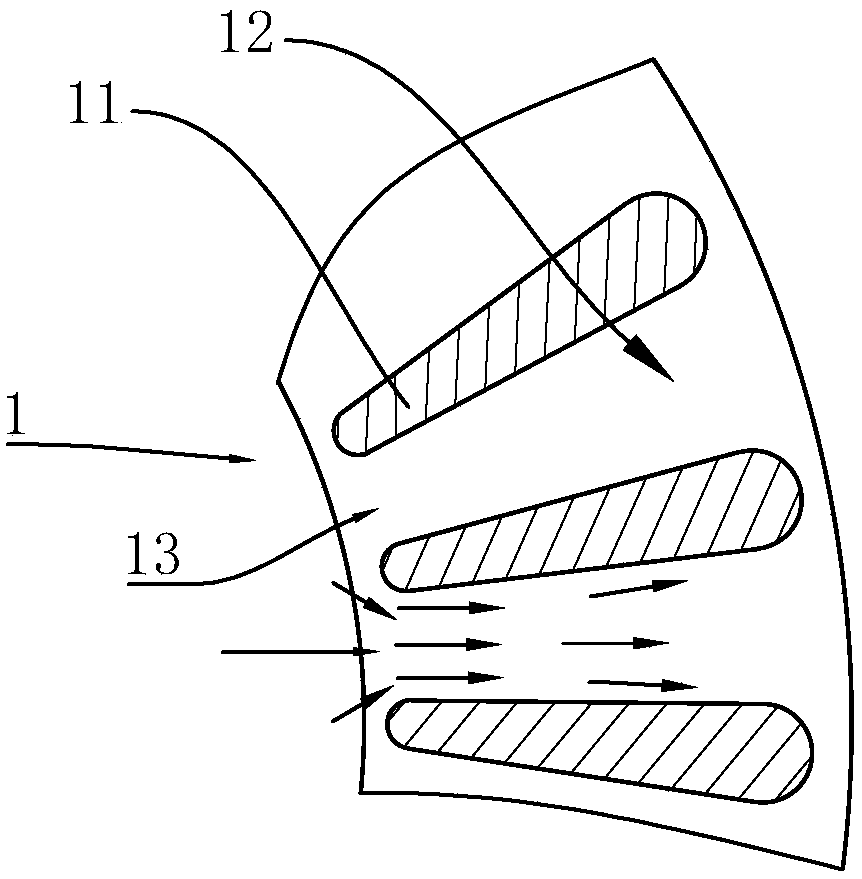

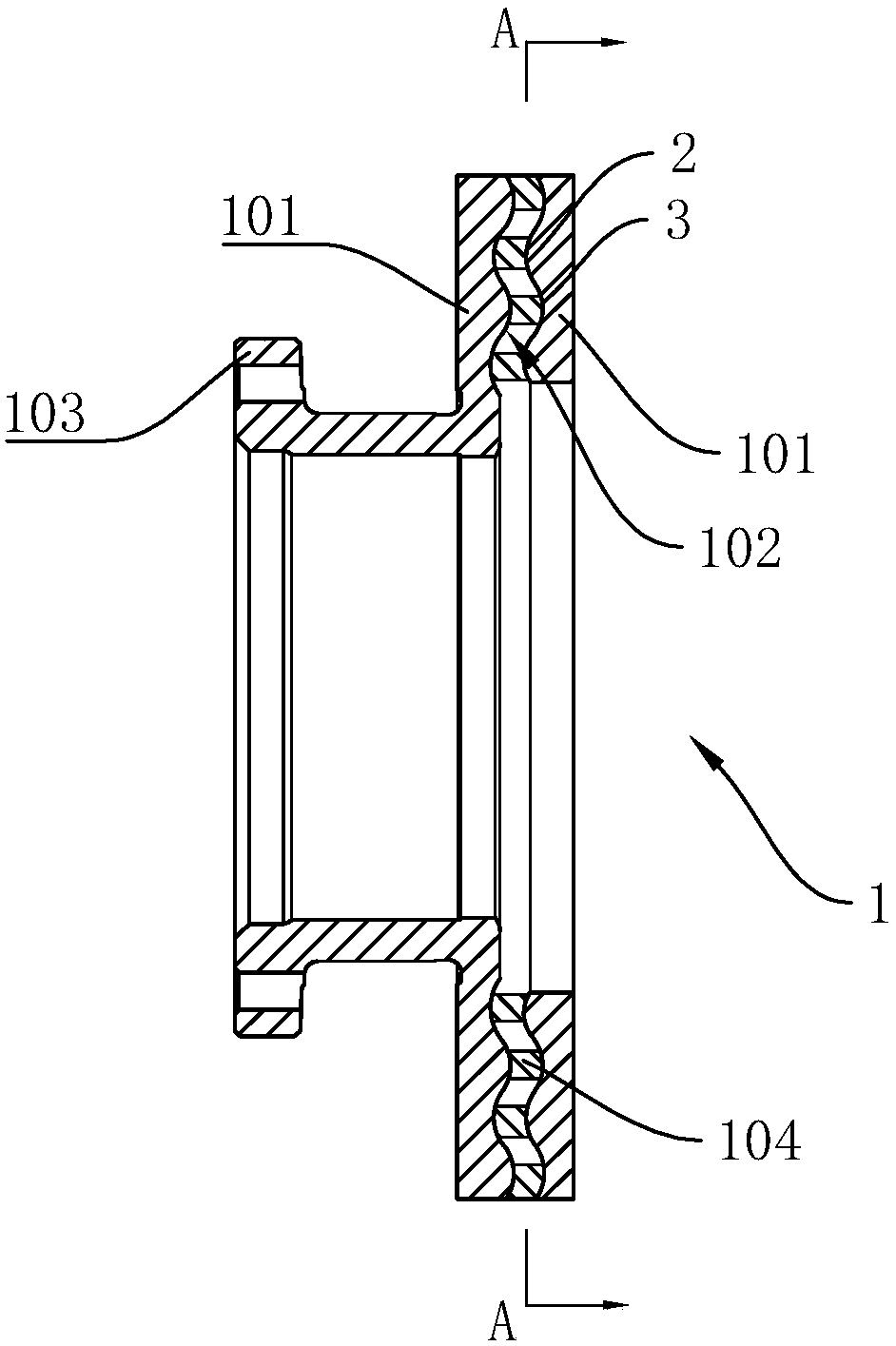

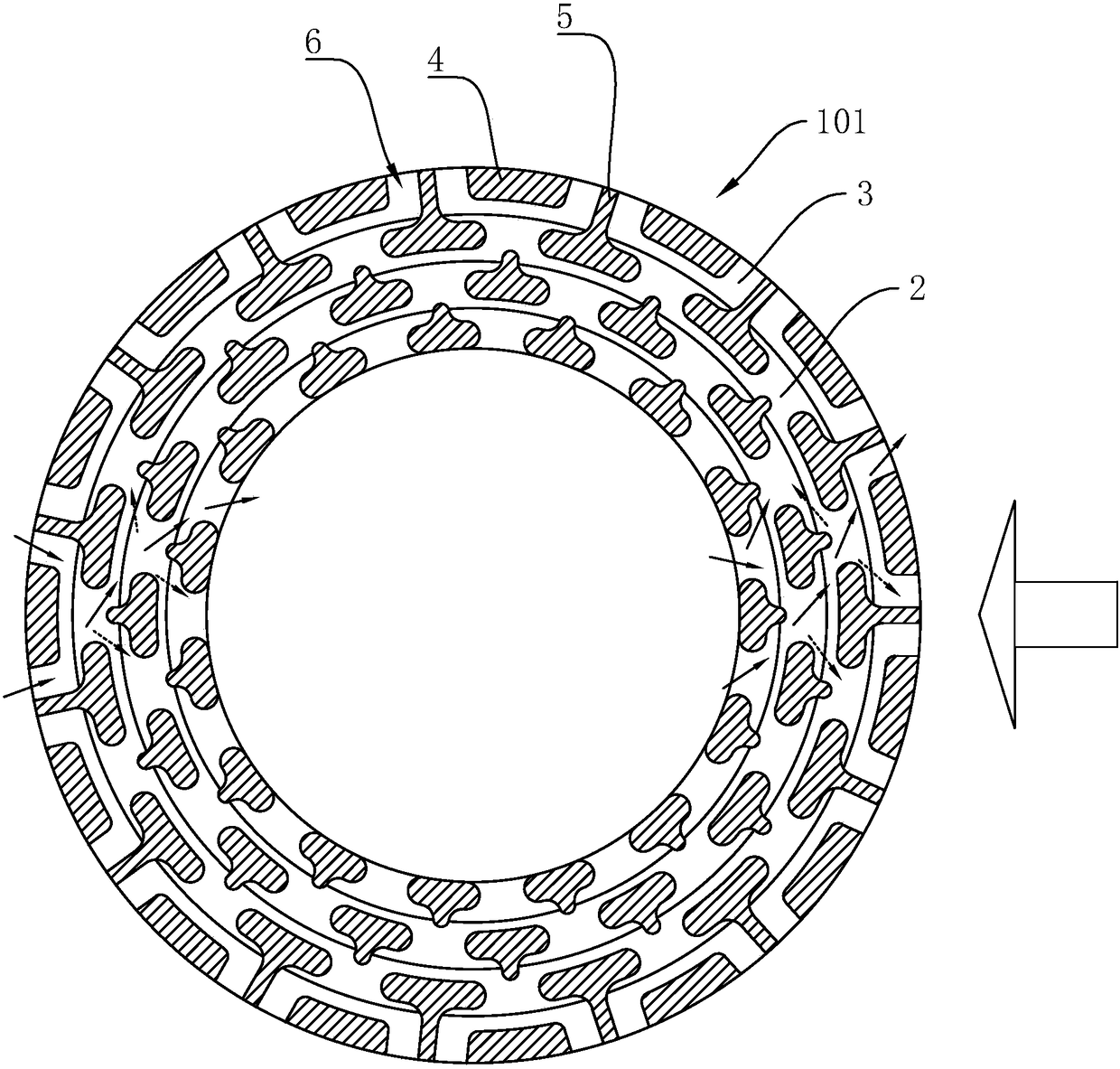

[0030] Such as figure 2 and image 3 Commonly shown, a brake disc includes a brake disc body 1, and the brake disc body 1 includes: two disc bodies 101 connected as one by connecting ribs 104, one of the disc bodies 101 is provided with a flange 103; the space between the two disks 101 constitutes the airflow channel 6, and each disk 101 has a disk surface 102 connected with the connecting rib 104, and the disk surface 102 of at least one disk 101 is wavy. The wave-shaped airflow passage 6 is formed between the two disk bodies 101 through the wave-shaped disk surface 102. When the airflow passes through the brake disc body 1, it will roll in the wave-shaped airflow passage 6 and form a certain acceleration. , not only increases the contact area between the airflow and the disc body 101, prolongs the residence time of the airflow in the airflow channel 6, but also increases the flow velocity of the airflow, so that the airflow is fully heated, that is to say: the airflow in t...

Embodiment 2

[0040] Such as figure 2 and Figure 4 Commonly shown, the specific structure of this embodiment is the same as that of Embodiment 1, the difference being:

[0041] The specific distributions of the annular ribs 4 and the radial ribs 5 on the disk surface 102 are different, specifically:

[0042] In the circumferential direction, there are multiple annular rib array groups and radial rib array groups. The annular ribs 4 are arranged in a staggered manner. Based on the outer circumference of the disk surface 102 , the radiating ribs 5 in the radiating rib array group extend from the outside to the inside, and extend to the corresponding annular ribs 4 . In this scheme, every three radial ribs 5 on the outer ring extend to the annular rib 4, and extend to the middle of the annular rib 4, and the radial ribs 5 on the inner ring are not connected to the annular rib 4; Air flow passages 6 are provided between the radial radial ribs 5 and the annular ribs 4 , between two adjacen...

Embodiment 3

[0046] Such as figure 2 and Figure 5 Commonly shown, the specific structure of this embodiment is the same as that of Embodiment 1, the difference being:

[0047] In a radially adjacent radial rib array group and an annular rib array group, the annular rib array group is located outside the radial rib array group, and the annular rib 4 in the annular rib array group is provided with a first point extending inward Head 401. Preferably, the radiating ribs 5 in the radiating rib array group are provided with second pointed portions 501 extending outward, and the second pointed portions 501 are arranged alternately with the first pointed portions 401 .

[0048] In this embodiment, the specific structure of the annular rib 4 and the radial rib 5 on the disk surface 102 is as follows:

[0049] A radial rib array group is provided near the outer and inner circumference of the disk surface 102, and an annular rib array group is arranged between the two radial rib array groups. Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com