Fastener

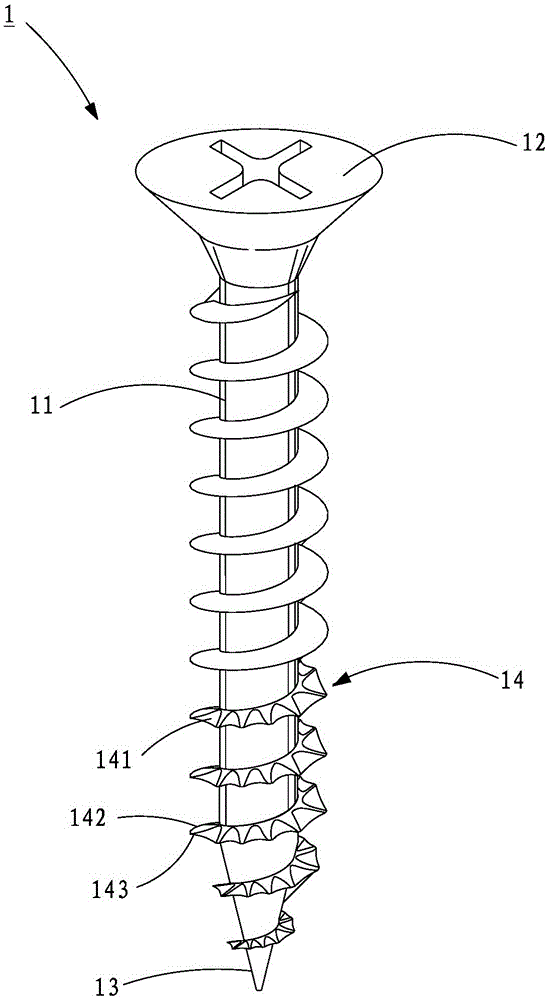

A technology for fasteners and threads, which is applied in the field of fasteners with tensile strength and anti-loosening, and can solve the problems that the threads cannot bear the screw-in torque, damage the lock, and the cutting ability of the notch 141 is not good enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

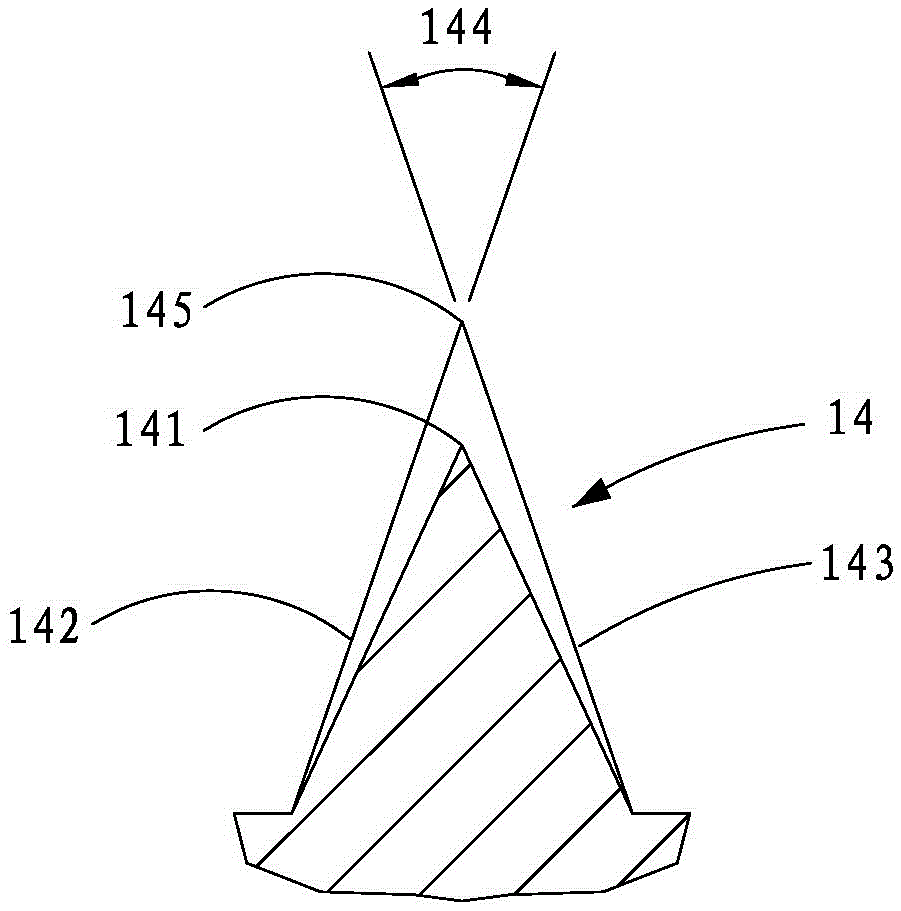

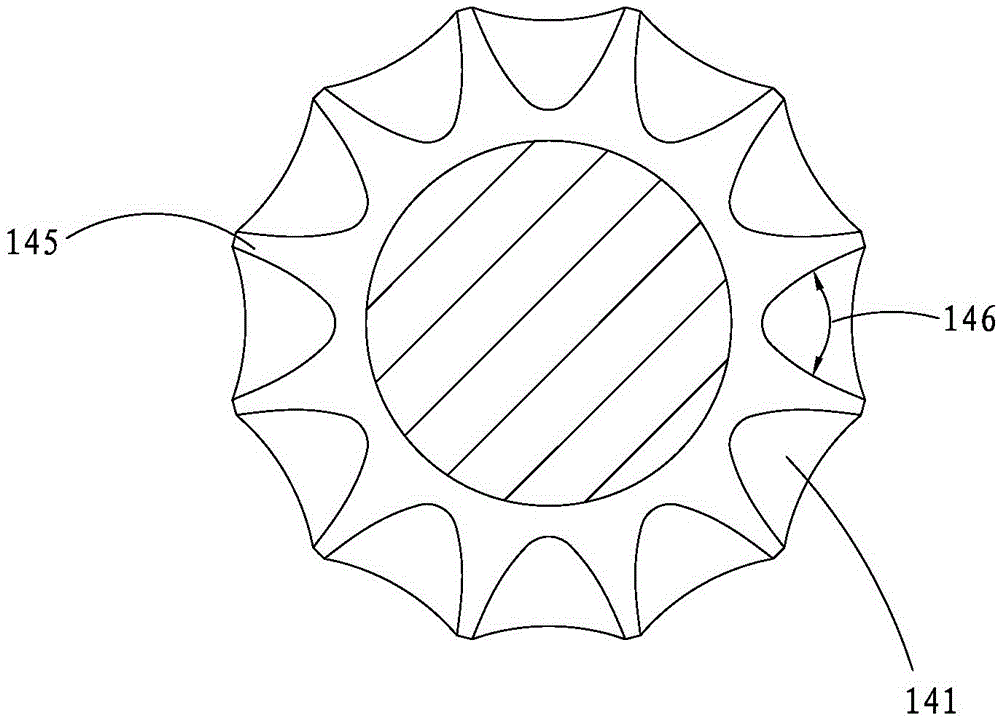

[0055] refer to Figure 4 to Figure 6, the first preferred embodiment of the fastener 3 of the present invention, which includes a rod body 31, a screw head 32 provided on the rod body 31, a lock opposite to the screw head 32 and provided at the other end of the rod body 31 part 33, and a plurality of first threaded teeth 34 and second threaded teeth 35 respectively arranged on the rod body 31; wherein, each first threaded thread 34 extends from the locking part 33 to the direction of the screw head 32 and is arranged around the ring. On the rod body 31, each first thread 34 has a first upper tooth surface 341 extending downward from the rod body 31, a first lower tooth surface 342 extending upward from the rod body 31, and a The first crest 343 formed by the connection of the first upper and lower tooth surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com