Suspended type oil submersible direct drive screw pump oil extraction device

A technology of oil extraction device and screw pump, which is applied to pump devices, components of pumping devices for elastic fluids, non-displacement pumps, etc., can solve the problems of complicated lifting and lowering operation procedures, high labor intensity, and easy wear of cables. , to achieve the effect of low safety and environmental protection risk, high degree of automation, and easy card release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

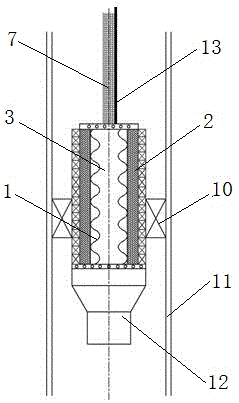

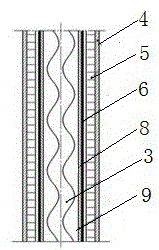

[0020] In order to overcome the problems that cables are easy to wear, drill tools are easy to get stuck, high safety risks, complex tripping procedures, low efficiency, and high labor intensity during the downhole process, this embodiment provides a method such as figure 1 with figure 2 The suspended oil submersible direct drive screw pump oil production device shown includes a screw pump 1 and a submersible motor 2, the screw pump 1 and the submersible motor 2 are fixed by welding, and the screw 3 of the screw pump extends into the inside of the submersible motor 2 , the submersible motor 2 includes a motor casing 4, a motor stator 5, and a motor rotor 6, the upper end of the motor casing 4 is connected with a steel wire rope 7 and a cable 13, and the inside is a motor stator 5 and a motor rotor 6, and the inside of the motor rotor 6 is A bushing 9 is connected via a connecting piece 8 .

[0021] The operating principle of this suspended submersible direct drive screw pump...

Embodiment 2

[0025] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the suspension type submersible direct-drive screw pump oil production device shown, the submersible motor 2 is covered with a packer 10 , and the packer 10 is covered with a casing 11 . The packer 10 has double sealing and anti-jamming functions, and a casing 11 is sheathed outside the packer 10, which solves the problems that the cable is easy to wear and the drilling tool is easy to get stuck during the downhole process.

[0026] Further, the lower end of the submersible motor 2 is connected with a supporting slip 12 . The supporting slip 12 has a high load capacity, is easy to operate, and is easy to release. It can be suspended and seated by lifting up and down. When the device is lowered underground, the supporting slip 12 has a supporting function to protect the motor.

Embodiment 3

[0028] On the basis of embodiment 2, this embodiment provides a kind of figure 1 In the suspension-type submersible direct-drive screw pump oil extraction device shown, the steel wire rope 7 is obtained by compacting the multi-strand wire contacting the round-strand steel core steel wire rope. The steel wire rope 7 has the characteristics of high rigidity, high elastic modulus, good impact resistance, good wear resistance, stable structure, etc., which ensures safety and reliability in the lifting and lowering operation process.

[0029] The bushing 9 is made of rubber. There is certain friction between the bush and the screw rod 3 during the rotation process, and the bush made of rubber is used to reduce friction and protect the screw rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com