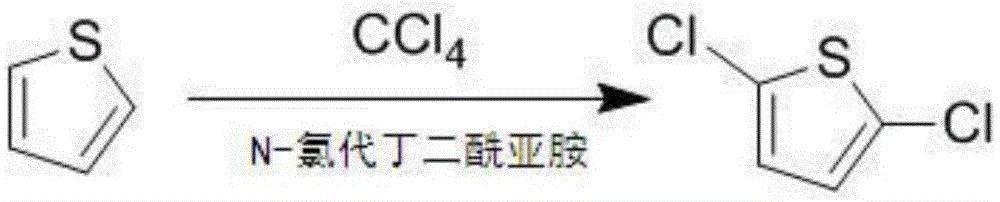

2, 5-dichloro thiophene preparation method

A technology of dichlorothiophene and thiophene, which is applied in the field of preparation of 2,5-dichlorothiophene, can solve problems such as environmental pollution, and achieve the effects of clean preparation method, reduced dosage, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of 2,5-dichlorothiophene comprises: adding 231g of carbon tetrachloride and 84g of thiophene in a 1000ml three-necked flask, heating up to reflux, and adding 200g of N-chlorobutyl in batches under the condition of reflux Diimide, backflow obtains reaction solution after 3.5 hours; The reaction solution in step 1 is cooled to room temperature, filters and removes impurity, then concentrates and recovers the carbon tetrachloride in the filtrate to obtain remaining reaction solution; Step 2 The temperature of the remaining reaction solution was raised to 100°C, and rectification under reduced pressure was carried out. The fraction at 100°C was collected, and the fraction at 100°C was collected as the target product of 2,5-dichlorothiophene to obtain 97g of 2,5-dichlorothiophene, 2, The yield of 5-dichlorothiophene was 63.4%, and the purity was 98%.

Embodiment 2

[0022] A preparation method of 2,5-dichlorothiophene comprises: adding 300g of carbon tetrachloride and 84g of thiophene in a 1000ml three-necked flask, heating up to reflux, and adding 270g of N-chlorobutyl in batches under the condition of reflux Diimide, reflux obtains reaction solution after 4 hours; The reaction solution in step 1 is cooled to room temperature, filters and removes impurity, then concentrates and recovers the carbon tetrachloride in the filtrate to obtain remaining reaction solution; Step 2 The temperature of the remaining reaction solution was raised to 100°C, and rectification under reduced pressure was carried out. The fraction at 100°C was collected, and the fraction at 100°C was collected as the target product of 2,5-dichlorothiophene to obtain 145g of 2,5-dichlorothiophene, 2, The yield of 5-dichlorothiophene was 95%, and the purity was 98.5%.

Embodiment 3

[0024] A preparation method of 2,5-dichlorothiophene comprises: adding 385g carbon tetrachloride and 84g thiophene in a 1000ml three-necked flask, heating up to reflux, and adding 334gN-chlorobutyl in batches under the condition of reflux Diimide, reflux obtains reaction solution after 4.5 hours; The reaction solution in step 1 is cooled to room temperature, filters and removes impurity, then concentrates and recovers the carbon tetrachloride in the filtrate to obtain remaining reaction solution; Step 2 The temperature of the remaining reaction solution was raised to 100°C, and rectification under reduced pressure was carried out. The fraction at 100°C was collected, and the fraction at 100°C was collected as the target product of 2,5-dichlorothiophene to obtain 145g of 2,5-dichlorothiophene, 2, The yield of 5-dichlorothiophene was 95%, and the purity was 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com