Full-automatic shuttling intelligent warehousing system

An intelligent warehousing and fully automatic technology, applied in the field of fully automatic shuttle intelligent warehousing system, can solve the problems of low efficiency and high labor intensity, achieve the effect of large storage capacity, fast operation speed and improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical idea claimed in the present invention more clearly.

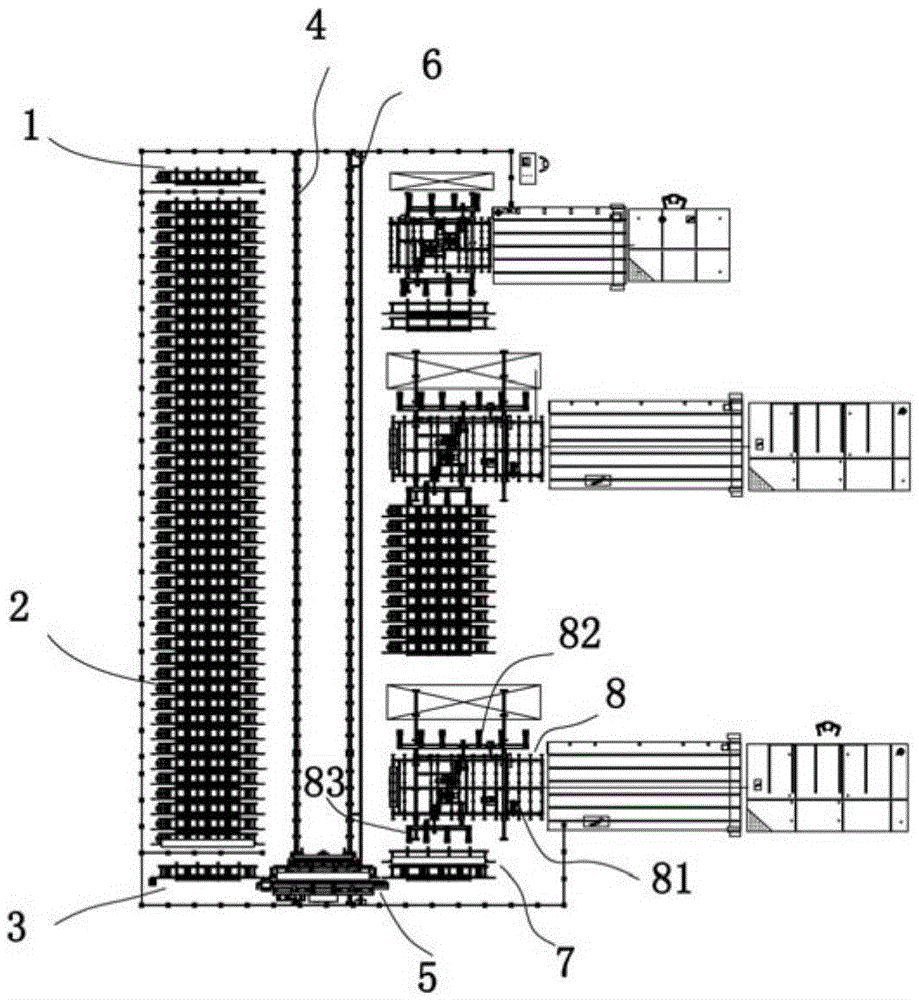

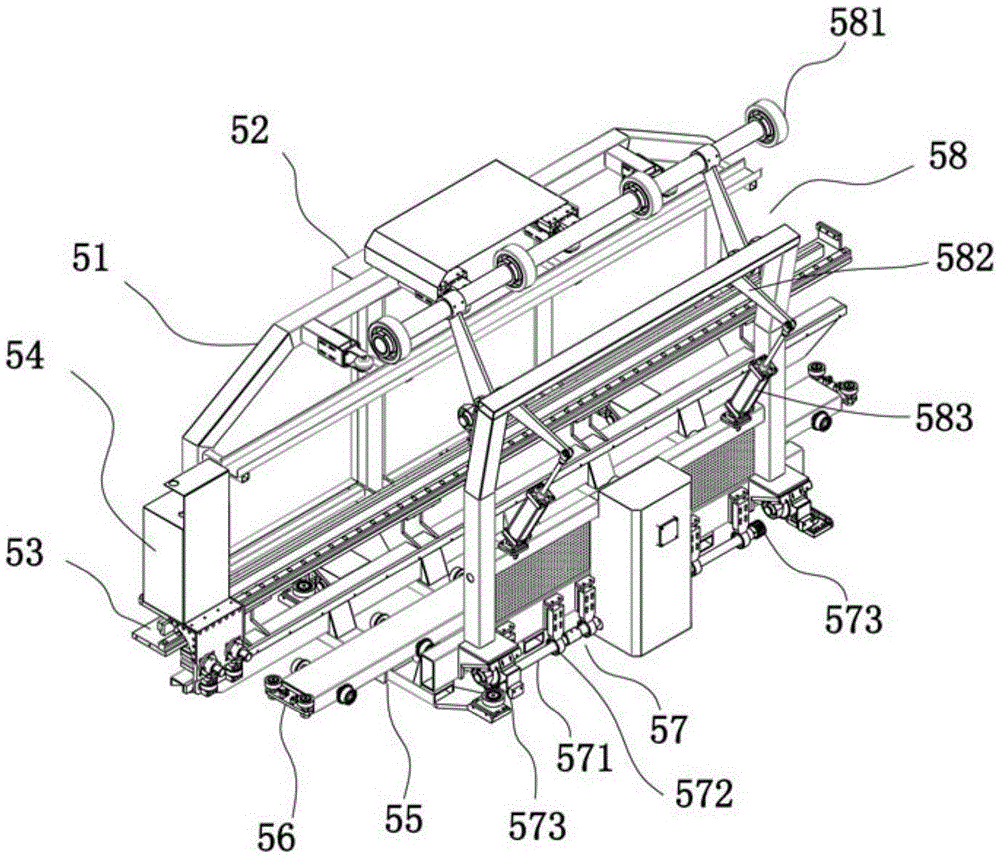

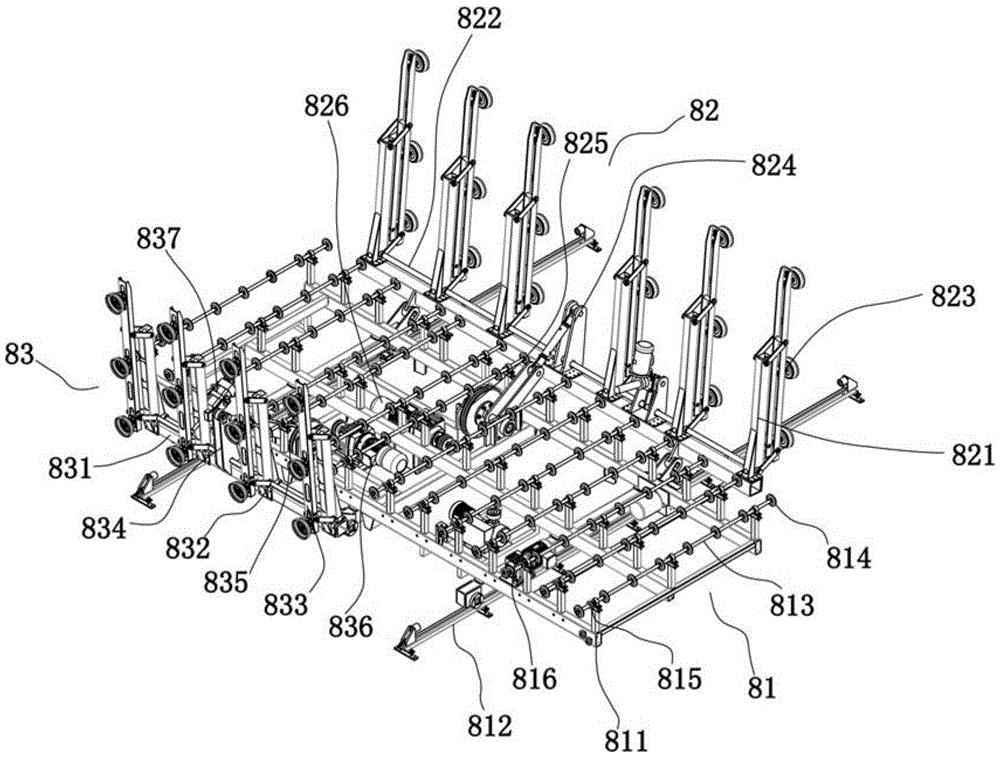

[0019] like figure 1 The shown automatic shuttle intelligent storage system of the present invention includes a first feeding station 1, a storage station 2, a second feeding station 3, a moving guide rail 4, a shuttle head 5, a power supply system 6, and a loading worker position 7 and loading station 8, the first feeding station 1 and the second feeding station 3 are arranged at both ends of the storage station 2, and the moving guide rail 4 is arranged along the length direction of the storage station 2 and is located at the storage station On the side of position 2, the shuttle head 5 is installed on the moving guide rail 4, the power supply system 6 is arranged parallel to the moving guide rail 4 and electrically connected to the shuttle head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com