Anti-static composite foamed block stamping base material

A compound foaming and anti-static technology, which is applied in the field of stamping substrates, can solve problems such as lack of vibration damping effect, broken objects, and gaps, etc., achieve good secondary processing performance, avoid static electricity, and reduce impact damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is further described

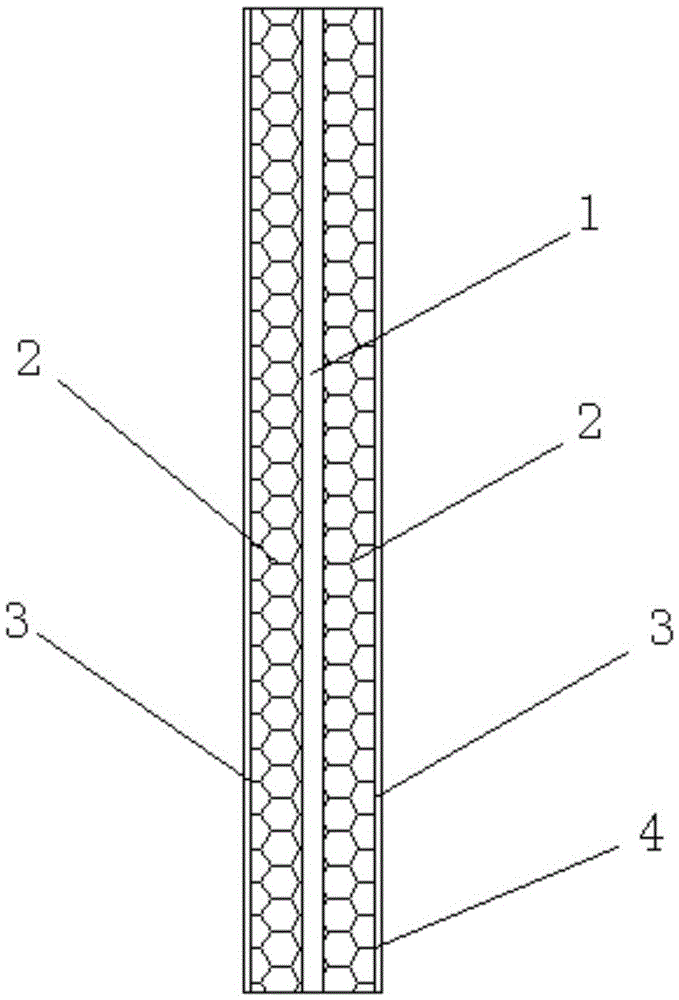

[0022] like figure 1 As shown, an antistatic composite foamed barrier stamping substrate includes an antistatic composite foamed barrier stamped substrate body 4, and the antistatic composite foamed barrier stamped substrate body 4 includes a hard and tough plastic sheet 1 , foaming material 2 and antistatic film 3, described antistatic composite foam block stamping base material body 4 is a kind of composite stamping base material, two surfaces near the outside are all provided with antistatic film 3, described antistatic The electrostatic film 3 is connected to the foam material 2 through the back glue, and the two sides of the hard and tough plastic sheet 1 are provided with cross textures, which can provide strong adhesion, and are strongly connected to the foam material 2 through the back glue.

[0023] Further, the foam material 2 is a closed-cell foam material or an open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com