A double-shaft garbage compression pretreatment machine

A garbage compression and preprocessing machine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of thick compression chamber, vibration due to eccentric movement, non-adjustable thickness of garbage blocks, etc., to achieve the effect of reducing costs and increasing the pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

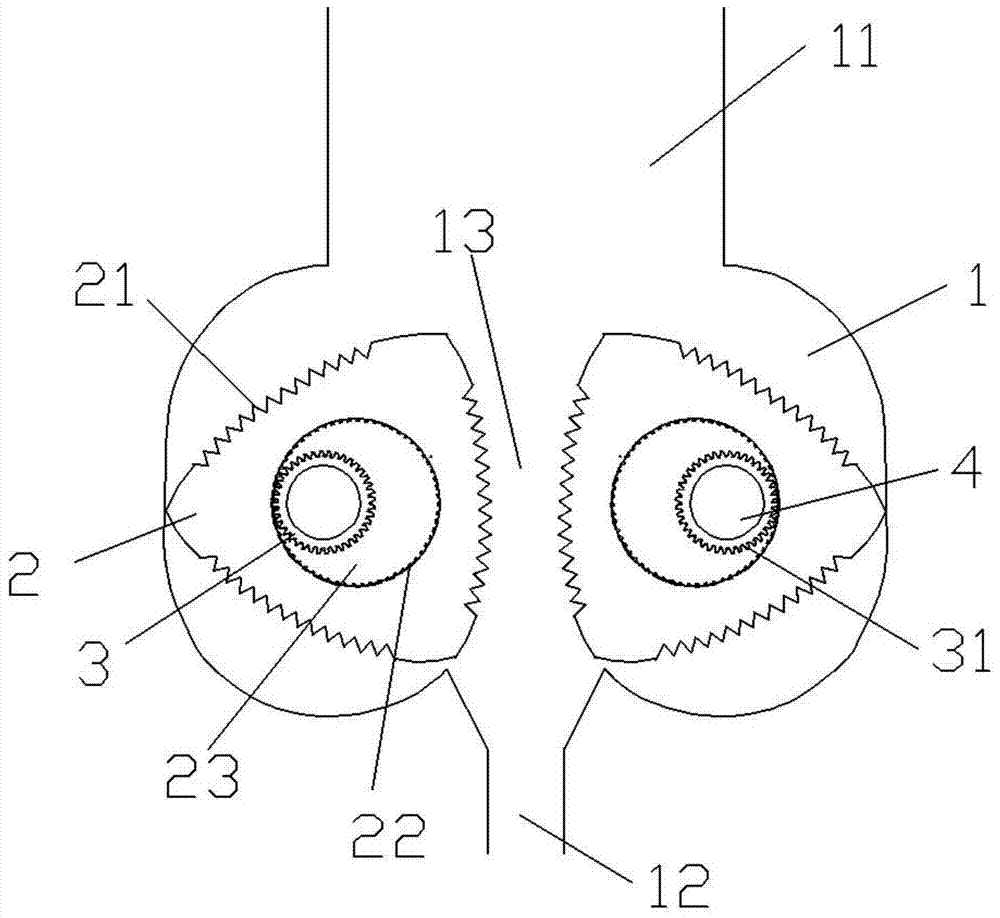

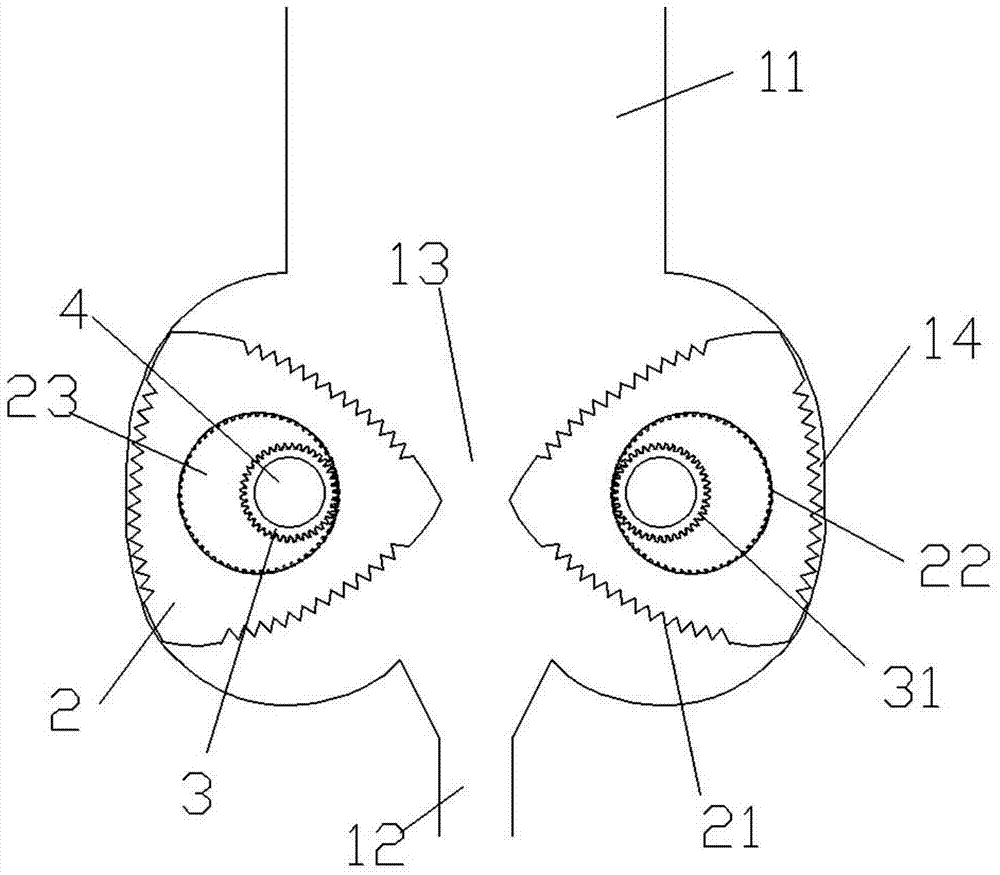

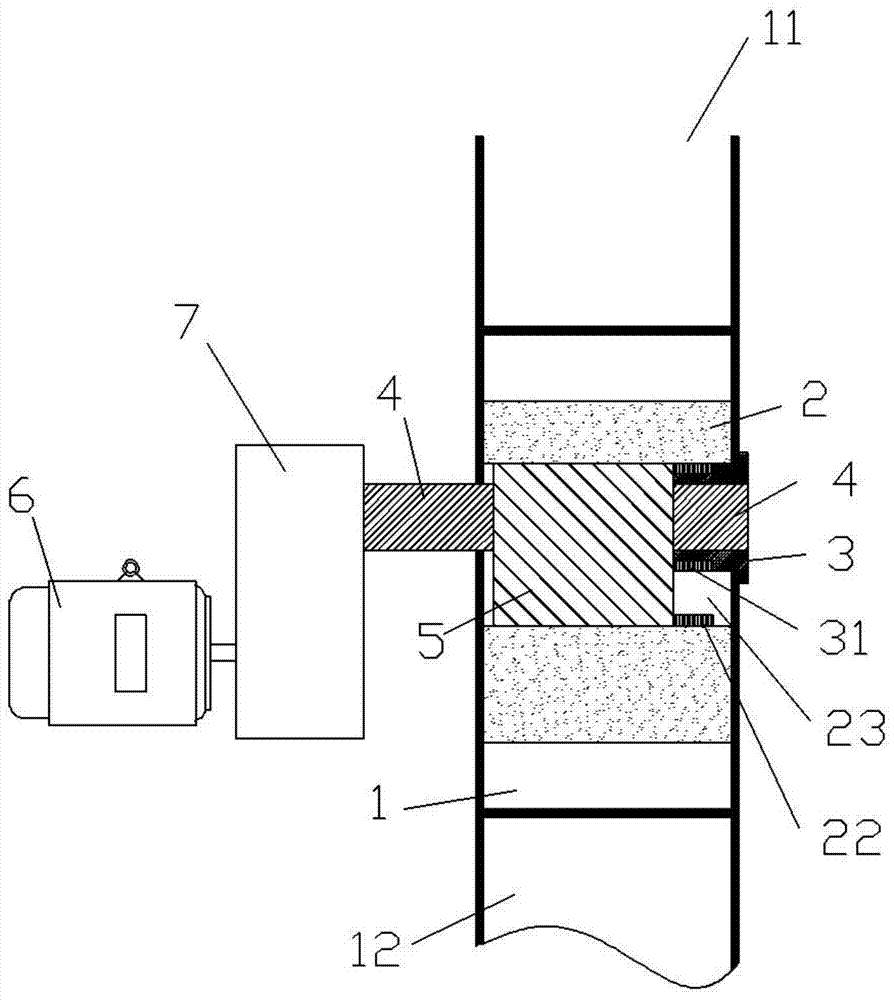

[0022] A two-axis garbage compression pretreatment machine, including a motor 6, a gear box 7, and a compression chamber 1, and a material inlet 11 and a material outlet 12 are respectively arranged above and below the compression chamber 1, and is characterized in that the compression box is in the shape of "∞" , composed of two symmetrical cocoon-shaped cavities on the left and right, two compression blocks 2 are set in the compression cavity 1, the compression block 2 is a Leroy triangular rotor structure, and a shaft hole 23 is set in the center of the compression block 2, and the shaft hole 23 A rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com