Female die for manufacturing wall thickness-variable glove and glove manufactured through female die

A technology of changing wall thickness and gloves, applied in the field of radiation protection products and protective equipment, can solve the problems of poor flexibility, unable to meet the flexible operation of doctors, etc., to achieve good water absorption, good protection effect and application prospects, and ensure the effect of flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

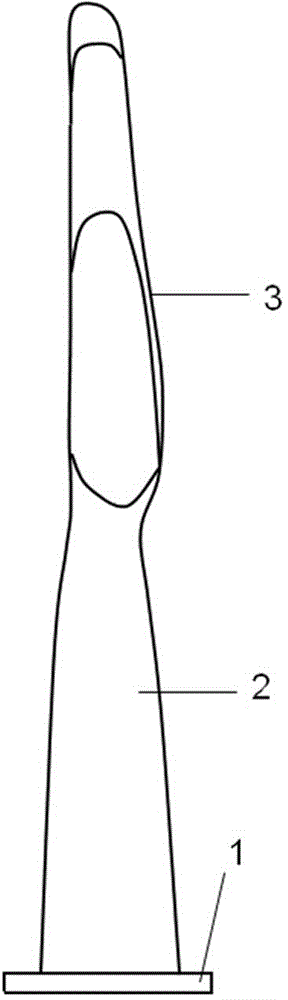

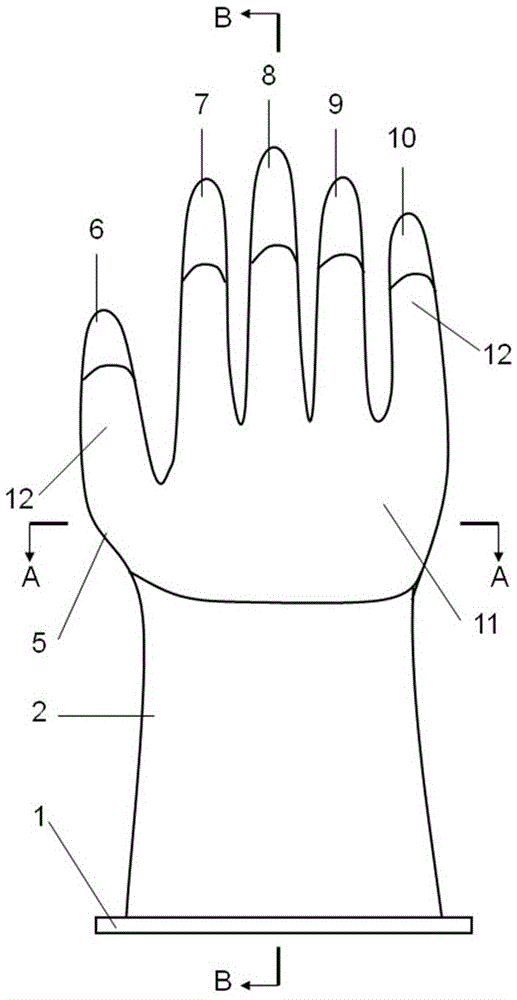

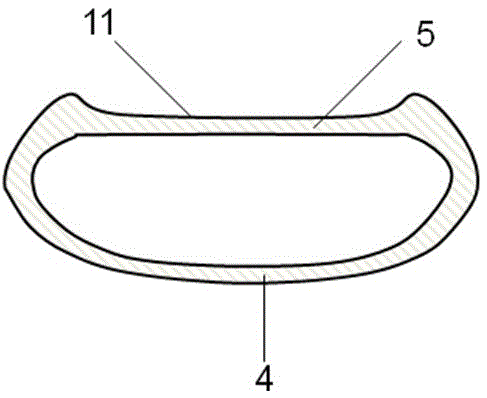

[0045] As shown in the figure, the female mold includes a base, an arm, a palm, and a finger. The base, the arm, the palm, and the finger are sequentially connected to form a whole, and the arm and the palm adopt a hollow structure. The fingers include a thumb part, an index finger part, a middle finger part, a ring finger part and a little finger part.

[0046] The back of the palm is provided with a first groove, and the thumb, index finger, middle finger, ring finger, and little finger are respectively provided with a second groove on one side of the back of the palm, and the second groove is connected to the first groove. connected, the depths of the first groove and the second groove are respectively 0.3-1.5 mm. The area of the second groove on the thumb part, the index finger part, the middle finger part, the ring finger part and the little finger part is 0.5 times the area of the thumb part, the index finger part, the middle finger part, the ring finger part and the...

Embodiment 2

[0055] As shown in the figure, the female mold includes a base, an arm, a palm, and a finger. The base, the arm, the palm, and the finger are sequentially connected to form a whole, and the arm and the palm adopt a hollow structure. The fingers include a thumb part, an index finger part, a middle finger part, a ring finger part and a little finger part.

[0056] In this embodiment, the back of the palm is provided with a first groove, and the thumb and forefinger are respectively provided with a second groove on one side of the back of the palm, the second groove is connected with the first groove, and the first The depths of the groove and the second groove are respectively 0.3-1.5mm. Different from Embodiment 1, in this embodiment only the second groove is provided on the thumb part and the index finger part. The area of the second groove on the thumb part and the forefinger part is 0.5 times the area of the thumb part and the forefinger part on the side of the back of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com