Automobile welding conveying line

A conveying line and welding technology, which is applied in the direction of conveyors, mechanical conveyors, auxiliary devices, etc., can solve the problems of reducing the accuracy of workpiece conveying, inability to achieve synchronization, complex and large structures, etc., and achieve improved conveying efficiency, easy maintenance, and conveying high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

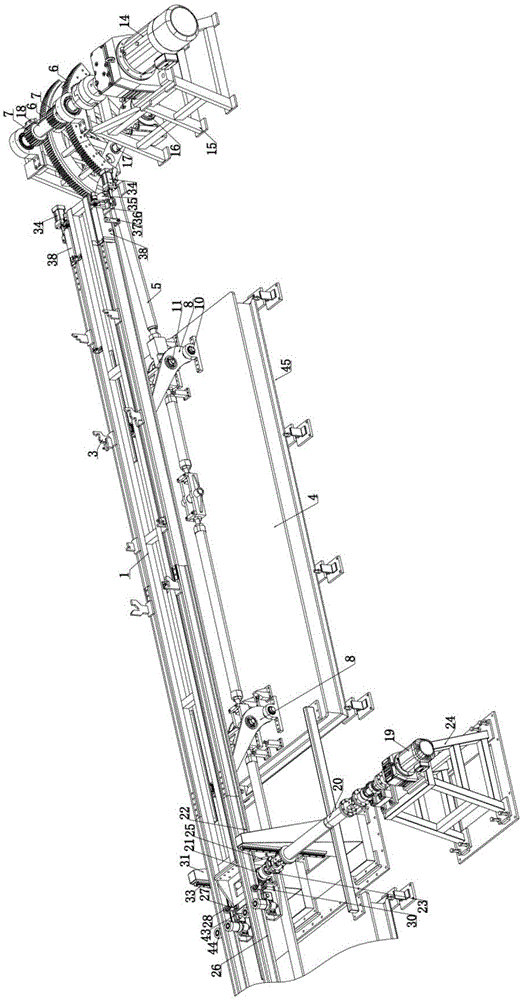

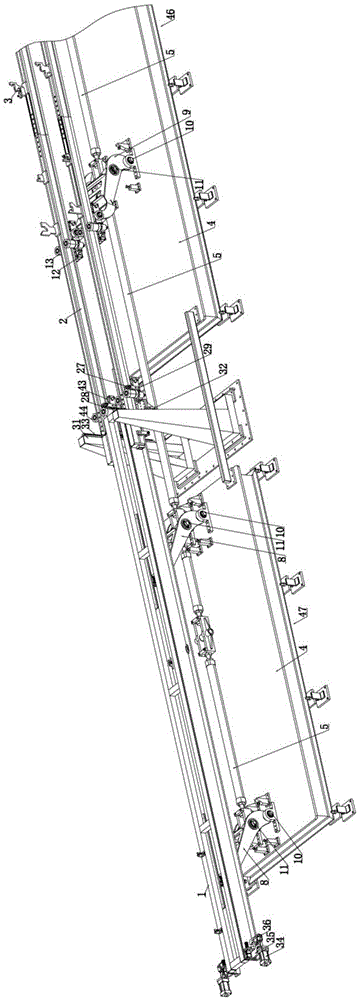

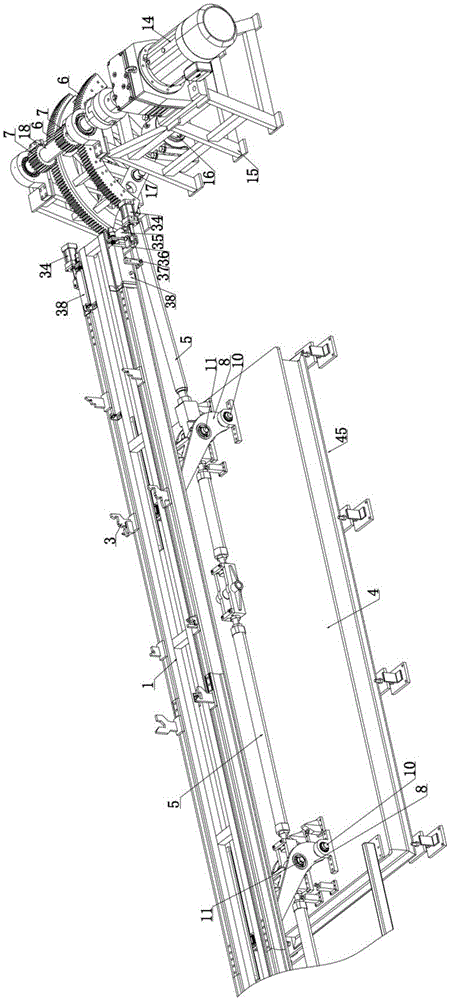

[0037] Such as Figure 1 to Figure 9 As shown, a kind of automobile welding conveying line, comprises the first station 45 that is arranged on the head end of the conveying line, a plurality of intermediate stations 46 and the empty station 47 that is arranged on the end of the conveying line, the first station and the empty station The stations are respectively provided with jacking frames 1, the jacking frames of the first station and the middle station are provided with two conveying beams in parallel, and the conveying beams are provided with supporting blocks 3 matched with workpieces, The jacking frame 1 and the conveying beam can move up and down synchronously under the action of the synchronous jacking mechanism, and the conveying beam can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com