Multi-zone electromagnetic stirring device and method for continuous casting machine crystallizer

An electromagnetic stirring and crystallizer technology, which is applied in the field of continuous casting equipment and electromagnetic stirring devices, can solve the problems of uniform growth of the primary slab shell, uneven internal structure of the slab, and uneven growth of the slab shell, etc. problems, to achieve the effect of promoting the floating of inclusions, improving the quality of casting slabs, and improving metallurgical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

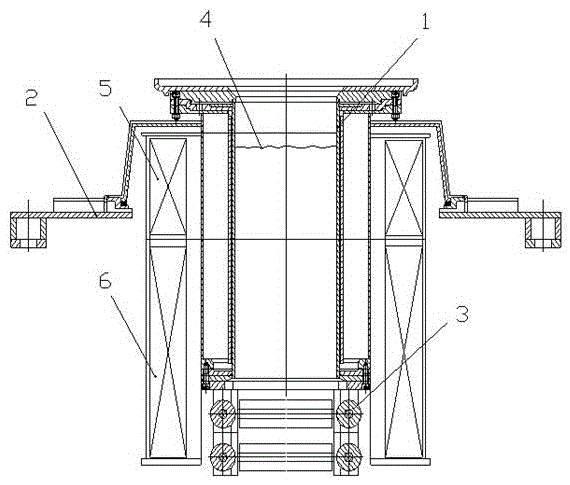

Image

Examples

Embodiment Construction

[0020] The technical principle of the present invention is that the intensity of electromagnetic stirring is a key parameter related to the metallurgical effect, and different regions of the crystallizer have different requirements for the intensity of stirring. The meniscus of the mold is the area where the shell of the primary slab begins to form. Electromagnetic stirring technology can be used to make the molten steel on the meniscus of the mold produce rotational movement. This movement can effectively improve the heat transfer efficiency in the mold and is beneficial to The uniformity of solidification of the billet shell, the rotational movement of molten steel cleans the solidification front to prevent non-metallic impurities and air bubbles from entraining to the first solidified skin to improve the surface quality. However, the meniscus area has strict requirements on the stirring intensity. Excessive stirring may easily cause slag rolling on the surface of the billet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com