Axial ventilating type high-efficiency stirrer

A ventilated and mixer technology, which is applied in the direction of mixer accessories, mixers, mixing methods, etc., can solve the problems of affecting the compounding (mixing) effect and reducing the quality of hydrometallurgical processing, so as to improve the quality of hydrometallurgy and increase the service life and use stability, improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

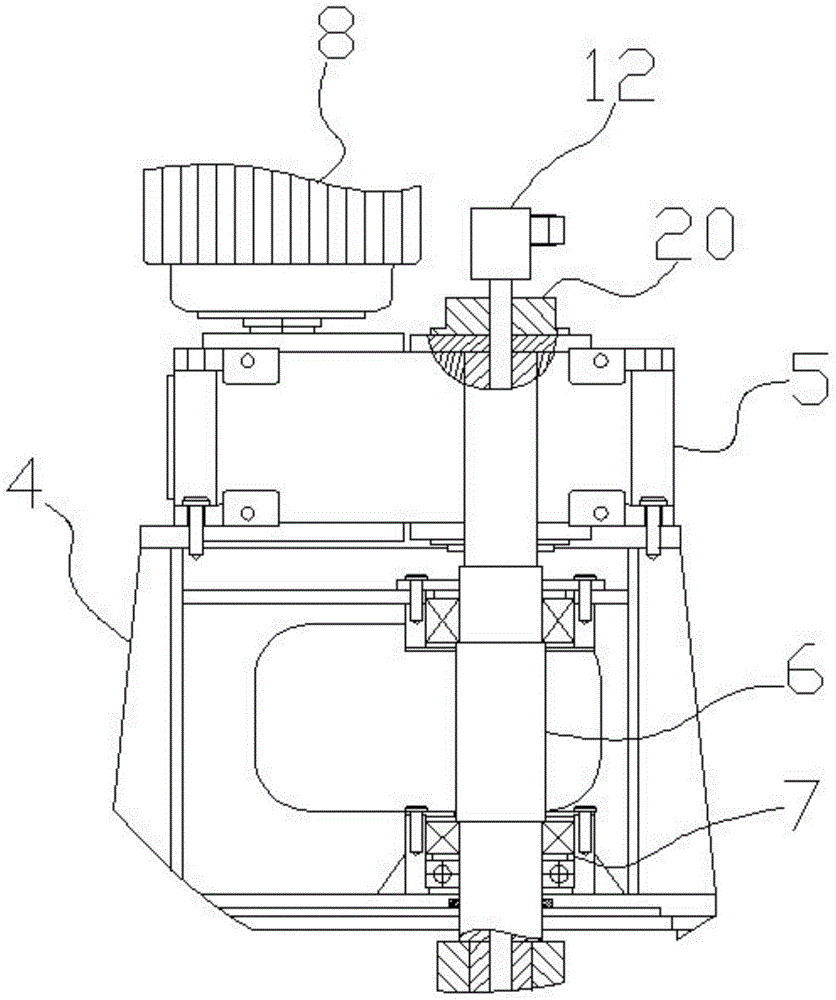

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

[0038] like Figure 1-Figure 4As shown, the specific structure of the present invention is: a shaft ventilated high-efficiency mixer, which includes a container 17 uniformly provided with a high-pressure vent pipe on the inner wall; a base plate 3 provided at the top of the container 17; An organic base 4 is arranged on the plate 3; a stirring motor 8 is arranged on the base 4; the stirring motor 8 is connected to the stirring rod 2; the stirring rod 2 is arranged in the container 17; machine 5; the input shaft of the reducer 5 is connected to the stirring motor 8, and the output shaft is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com