Sludge disposal integral equipment

A sludge disposal and equipment technology, applied in the field of integrated sludge disposal equipment, can solve the problems of affecting sludge conveying and composting treatment, poor proportioning accuracy, blocking the outlet of the silo, etc., and achieves convenient proportioning and mixing. The ratio is accurate and convenient, and the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

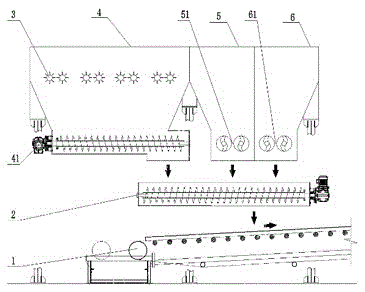

[0013] Such as figure 1 As shown, the present invention provides an integrated equipment for sludge disposal, including a belt conveyor 1, an open double-shaft mixer 2 located directly above the belt conveyor 1, and an open double-shaft mixer 2 located directly above the belt conveyor 2. The upper feed bin, the feed bin includes a clinker bin 4 with a downward opening, a raw material bin 5 and a raw feed bin 6, and the openings of the clinker bin 4, the raw feed bin 5 and the raw feed bin 6 are respectively provided with The clinker discharge biaxial screw 41, the raw material discharge biaxial screw 51 and the raw material discharge biaxial screw 61, the clinker bin 4 is provided with four evenly distributed feeders 3, the clinker bin 4 4. The raw material bin 5 and the raw material bin 6 are arranged side by side. The clinker discharging biaxial screw 41, the raw material discharging biaxial screw 51, the raw material discharging biaxial screw 61 and the open biaxial mixer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com