Battery connector for electric vehicle

A technology of battery connectors and electric vehicles, which is applied in the direction of electric vehicles, electric vehicle charging technology, vehicle connectors, etc., can solve the problems of poor locking degree, poor safety performance, inconvenient use, etc., and achieve good electrical conductivity and structure Compact, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

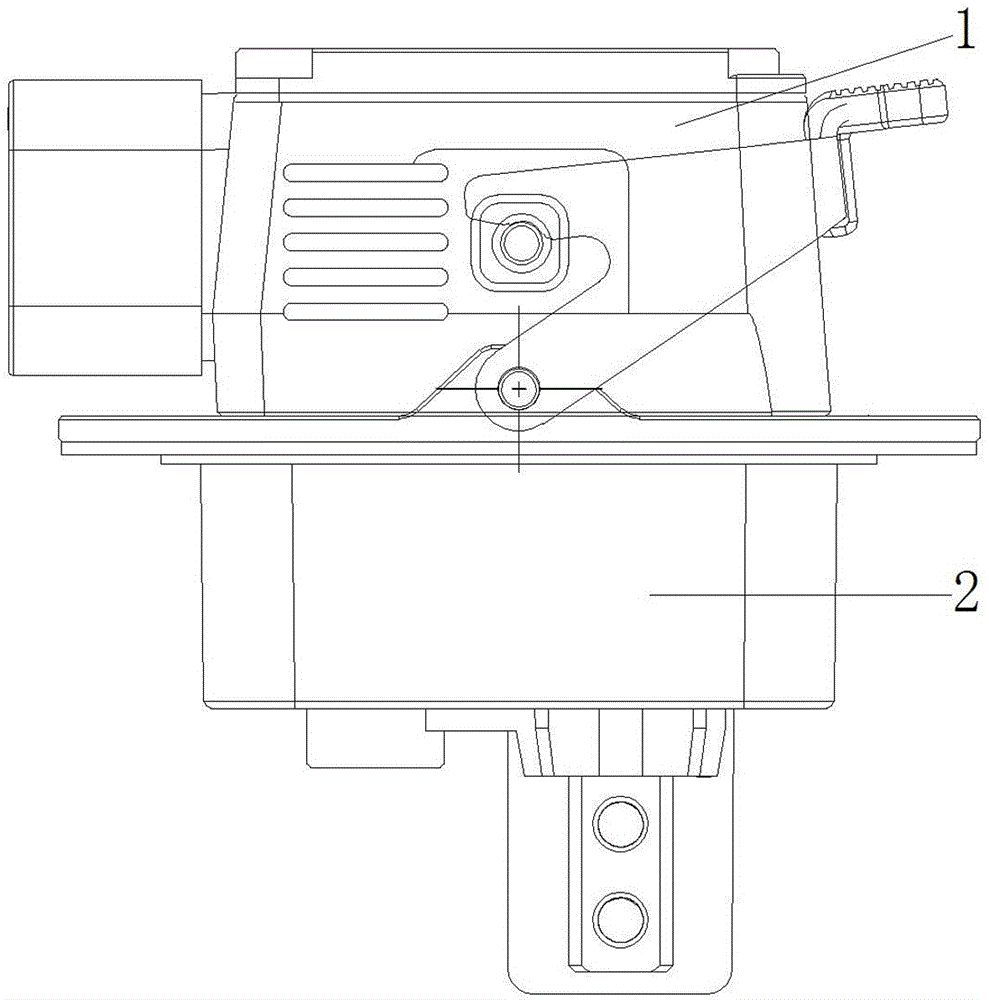

[0028] Refer to attached Figure 1-8 , the electric vehicle battery connector includes a connector plug 1 and a connector socket 2 .

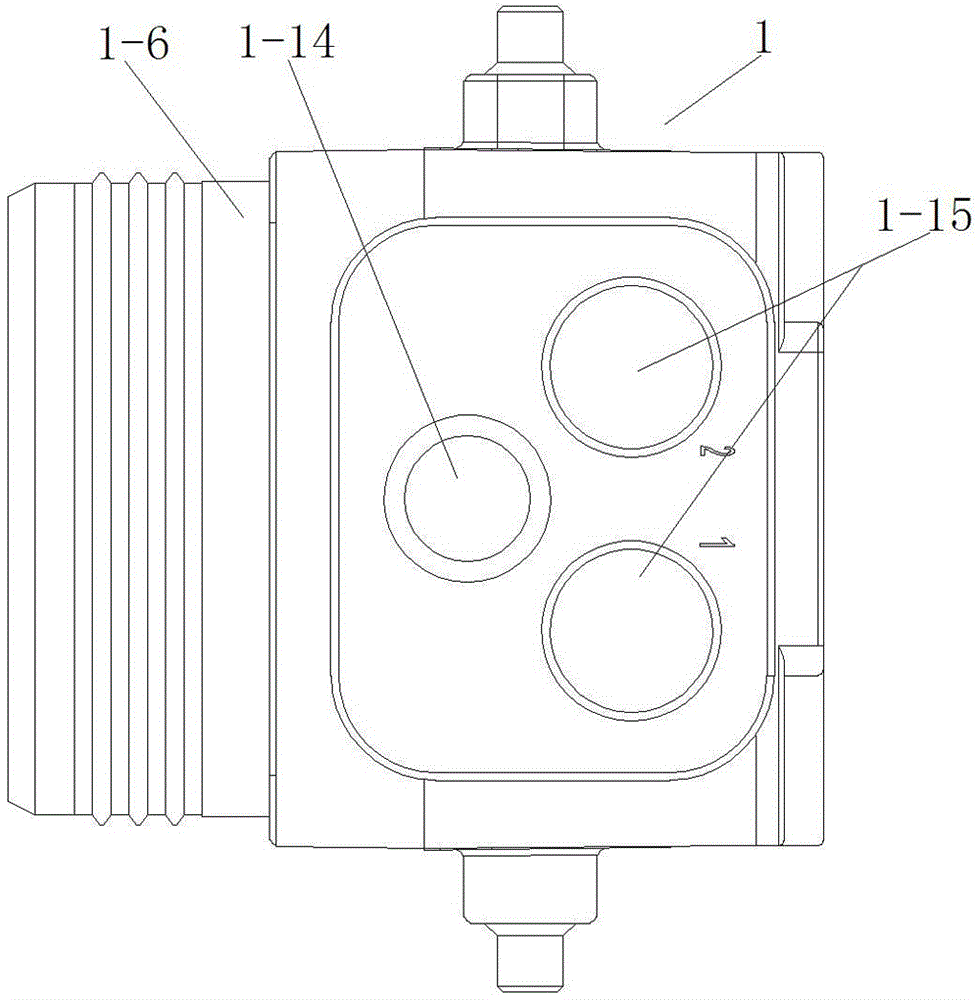

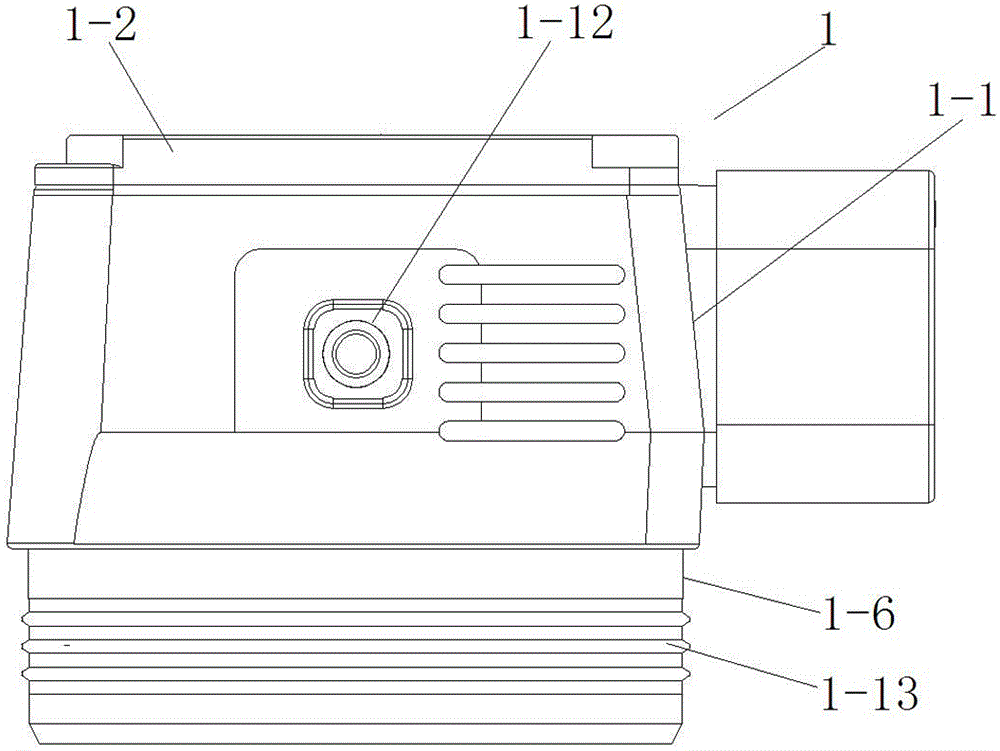

[0029] The connector plug 1 includes a plug housing 1-1, a sealing cover 1-2, a plug insulation mounting plate 1-3, a power plug 1-5 and a signal communication plug 1-4. A plug 1-6 is provided at the bottom of the plug housing 1-1. A plug insulating mounting plate 1-3 is installed in the plug housing 1-1, a power plug mounting seat 1-6 is arranged on the plug insulating mounting plate 1-3, and a power plug is provided on the power plug mounting seat 1-6 The installation hole 1-7 is equipped with a power plug 1-5 in the power plug installation hole 1-7, and the power plug 1-5 is provided with a positive power plug 1-8 and a negative power plug 1-9. Power plugs 1-5 use metal terminals (male pins). The front end of the power plug 1-5 is equipped with an insulating cap 1-16 to prevent hands from touching the metal terminals when inserting the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com