Very-low-profile cylindrical Luneberg lens antenna based on novel dielectric filling mode

A technology of Lunberg lens antenna and new medium, which is applied to antennas, electrical components, etc., can solve the problems of dense hole processing, large antenna loss, difficulty in processing and restricting use, etc., and achieve the effect of simple processing and low profile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the implementation methods and accompanying drawings.

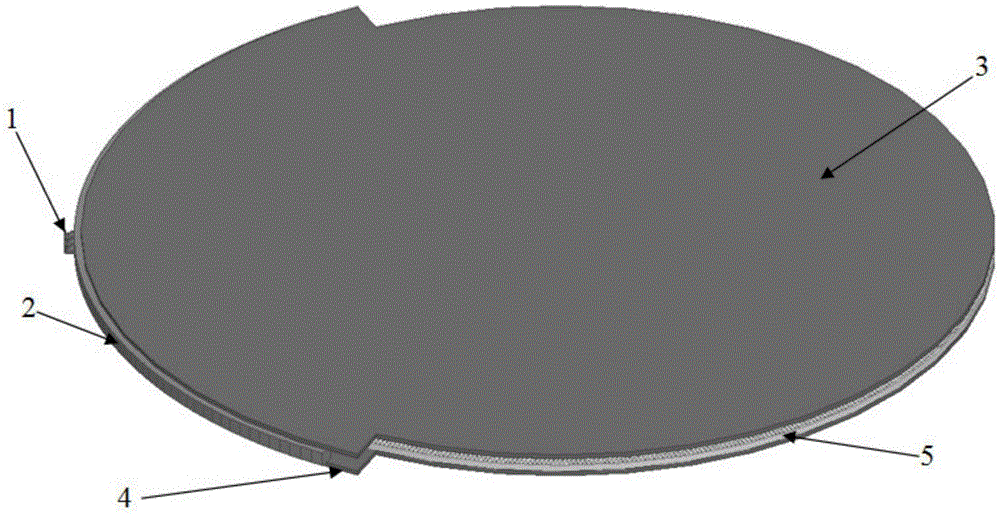

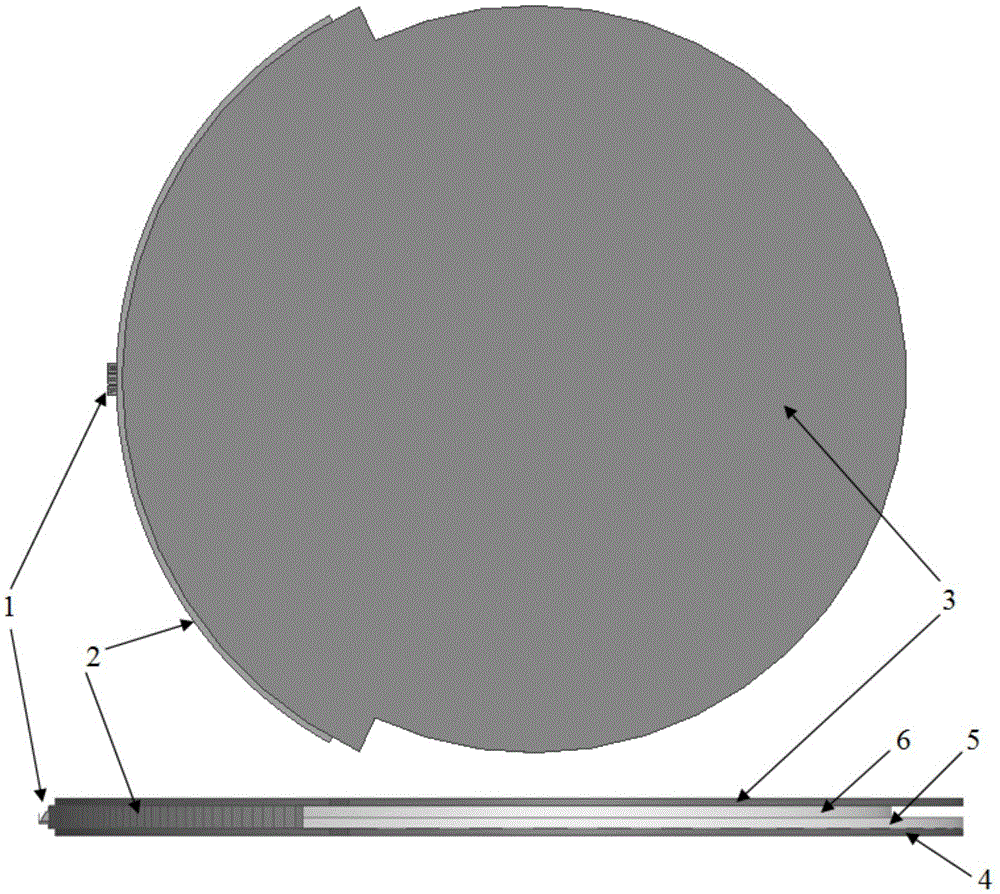

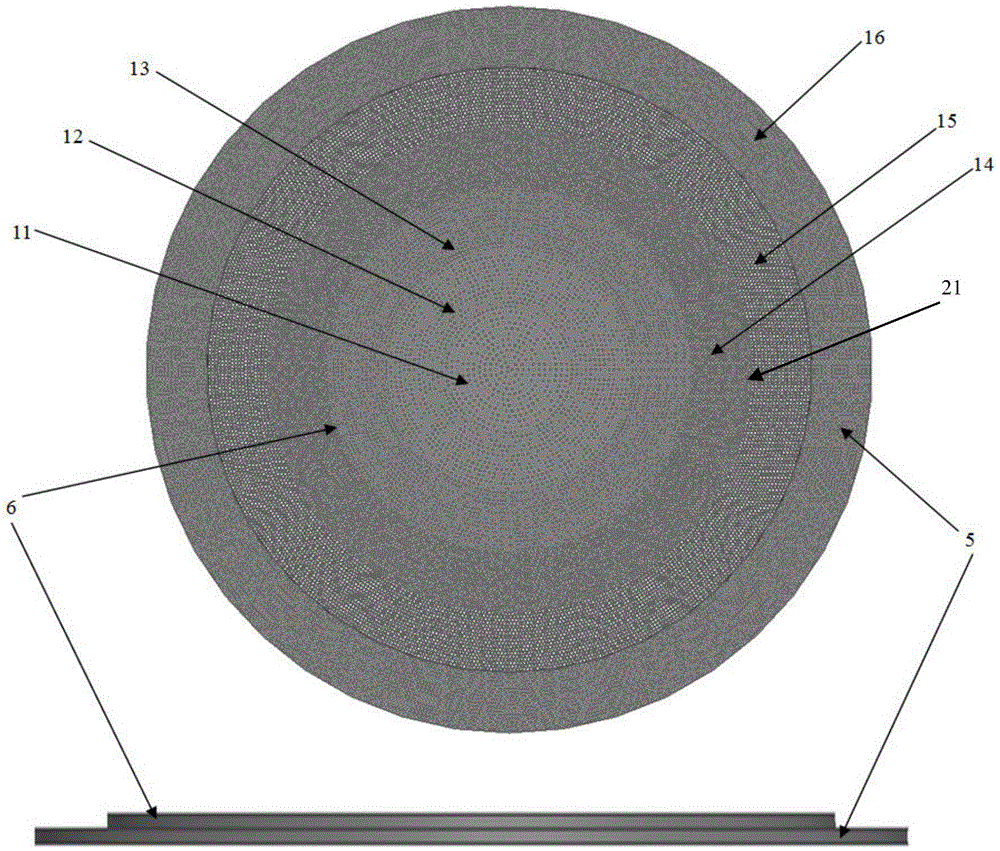

[0027] see figure 1 , figure 2 and image 3 , the cylindrical Lunberg lens antenna of the present invention comprises the cylindrical Lunberg lens between the upper metal cover plate 3 and the lower metal cover plate 4, and is fed by 3 open ridge waveguides (the spacing between adjacent feed sources is 1.5°) , to realize antenna multi-beam overlap within 3dB beam width) arc feed array 1 formed by arranging along the circumference where the focal point of the cylindrical Lunberg lens is located, and the arc-shaped feed array 1 located on the non-radiative aperture of the cylindrical Lunberg lens Metal reflective baffle 2 (which can effectively reduce the front-to-back ratio of the antenna radiation pattern), circular upper filling die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com