Lightweight dielectric-filled multi-beam cylindrical Luneberg lens antenna

A technology of dielectric filling and Lumber lens, which is applied in the direction of antennas and electrical components, can solve the problems of unfavorable weight, low antenna aperture efficiency, and poor anisotropy performance of lens antennas, etc., to reduce the overall height and reduce divergence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the implementation methods and accompanying drawings.

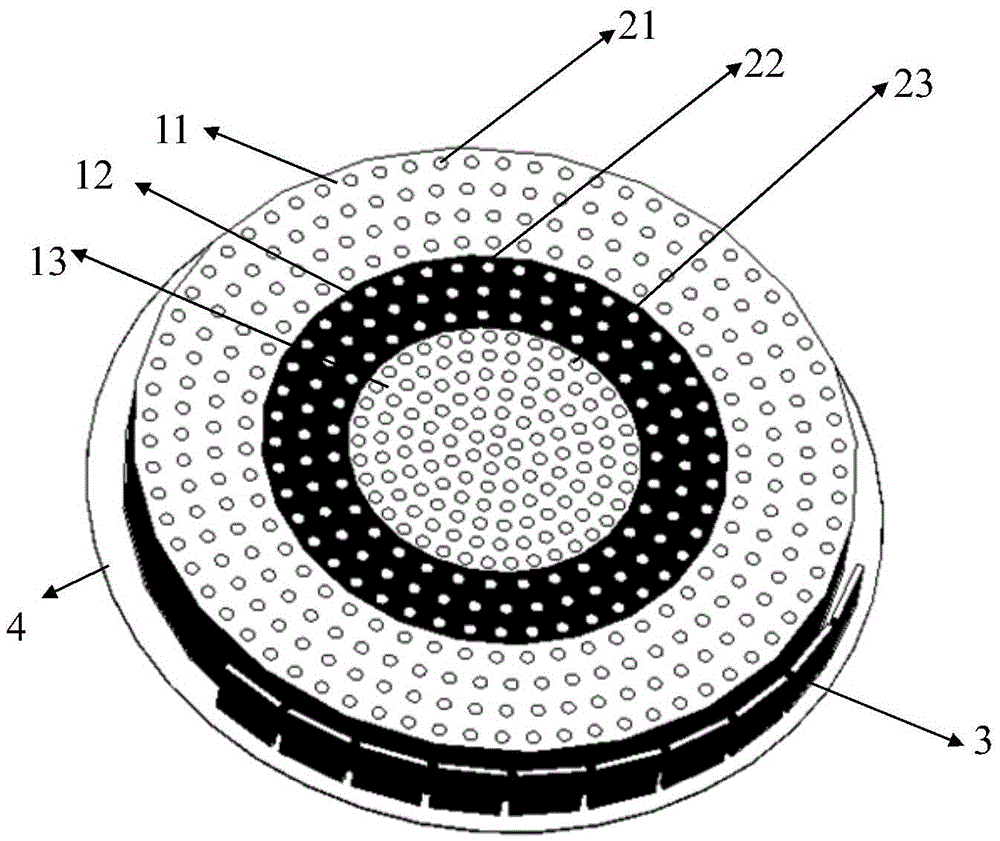

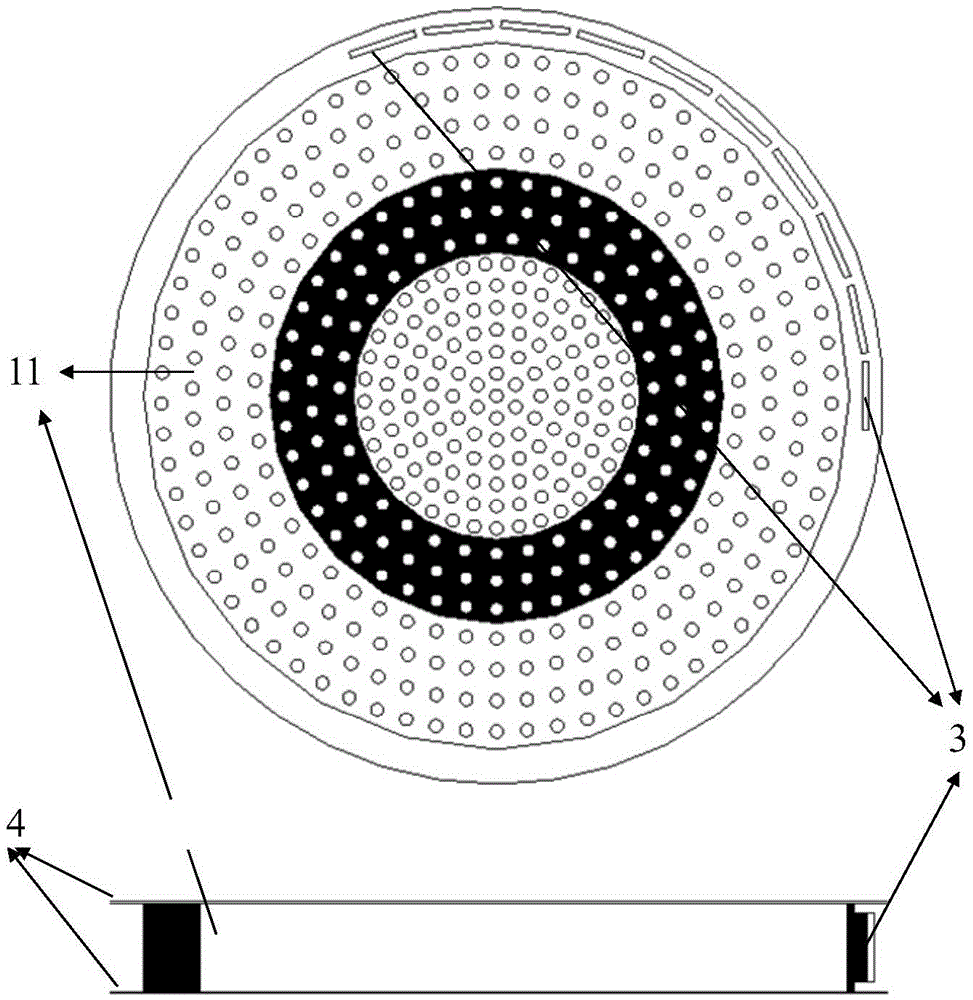

[0025] figure 1 and figure 2 The structural diagram of a lightweight dielectric-filled multi-beam cylindrical Lunberg lens antenna is described in detail. According to the illustration, the device mainly includes a cylindrical Lunberg lens antenna, an arc array 3 composed of 10 E-type microstrip patch feed sources, and two parallel metal plates 4, in which the cylindrical Lunberg lens consists of three layers : Outer layer lens 11, middle layer lens 12, inner layer lens 13, three-layer lens all adopts low dielectric constant lightweight substrate material, adopts lightweight foam as substrate material in the present embodiment, perforates and fills on substrate material High dielectric constant material, forming a dielectric rod. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com