Method for transferring gallium arsenide epitaxial layer to flexible metal substrate

A flexible substrate, gallium arsenide technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of large thickness, high weight, rigidity, fragility, non-bendable heat dissipation, etc., to expand the scope of application, Effect of reducing device weight and reducing voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

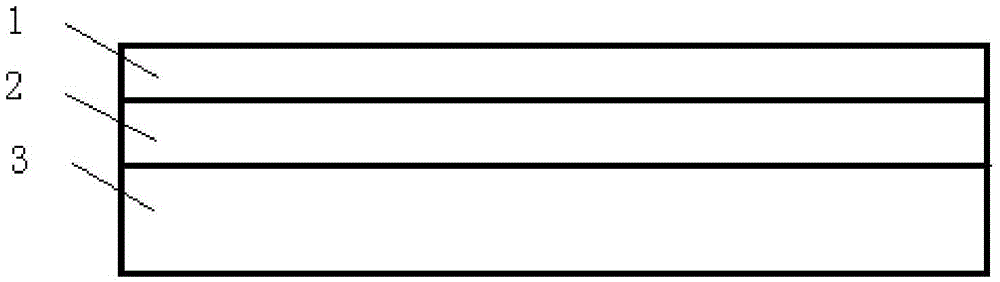

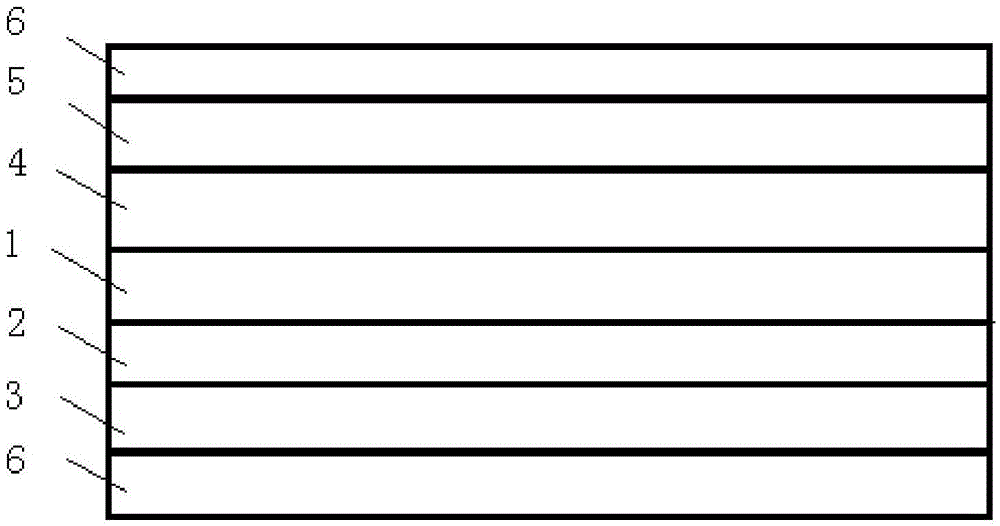

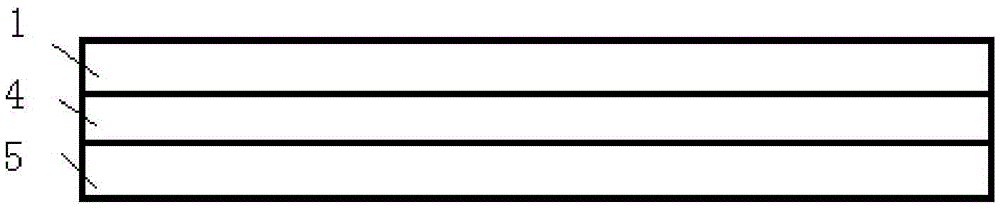

[0028] Such as Figure 1-3 As shown, the present invention transfers the gallium arsenide epitaxial layer to the method for the metal flexible substrate, and the specific method is as follows:

[0029] 1. Evaporation of bonding metal:

[0030] In order to realize the substrate transfer process, it is necessary to vapor-deposit the bonding metal layer on the epitaxial surface and the metal foil by vacuum evaporation at the same time. The evaporated layer metals are Ti and Au in turn, and the thicknesses are 100-500nm and 500-1000nm respectively. When evaporating, the vacuum degree is greater than 10 -6 Pa.

[0031] The epitaxial wafer structure adopted needs to add a GaInP barrier layer between the gallium arsenide substrate and the epitaxial layer, and its thickness is 50-500nm;

[0032] The thickness of the metal foil used is ≥0.008mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com