High temperature superconducting bending magnet structure appropriate for superconducting rotary rack technology

A rotating frame and high-temperature superconducting technology, which is applied to superconducting magnets/coils, magnetic objects, electrical components, etc., can solve problems such as error rotation accuracy, uneven force, and tonnage increase, and achieve high-current stability Operation, reduction of magnetic field flux leakage, effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

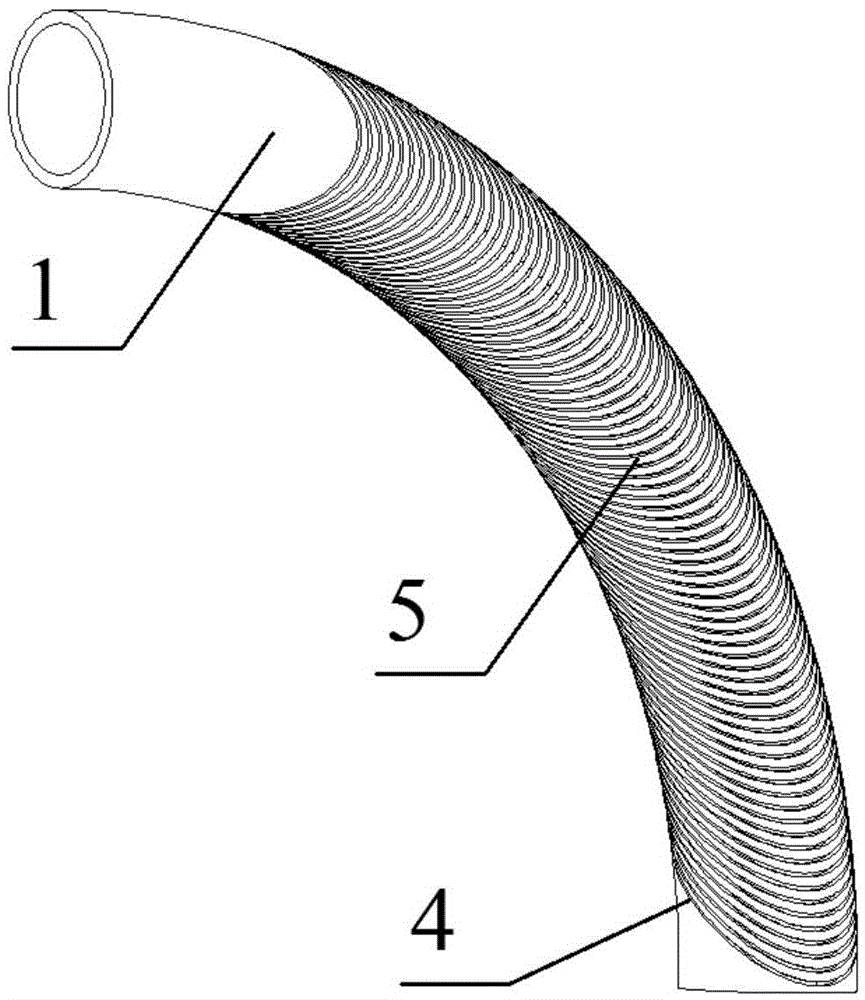

[0024] Reference manual attached Figure 1-3 , A high-temperature superconducting curved magnet structure suitable for superconducting rotating gantry technology, characterized in that it includes an inner coil 1 and an outer coil nested with the central axis, and the outer surface of the inner coil 1 is provided with an inclined arrangement Long groove one, the outer surface of the outer coil is provided with obliquely arranged long groove two, the inclination directions of the long groove one and the long groove two are symmetrical about the same central axis, and special The YBCO high-temperature superconducting conductor of the structure forms an inner conductor and an outer conductor. The inner conductor and the outer conductor are symmetrically wound and embedded on the outer surfaces of the inner coil and the outer coil. The magnetic field generated by the outer conductor is superimposed on each other, and finally a single-directional high-strength steady-state uniform m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com