An infrared detection method and detection equipment for automatic positioning detection position

A detection position and infrared detection technology, applied in the field of infrared detection, can solve the problems of low detection efficiency, inability to accurately locate and adjust the detection position and field of view, and inability to detect hidden defects and quality defects of components, so as to improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

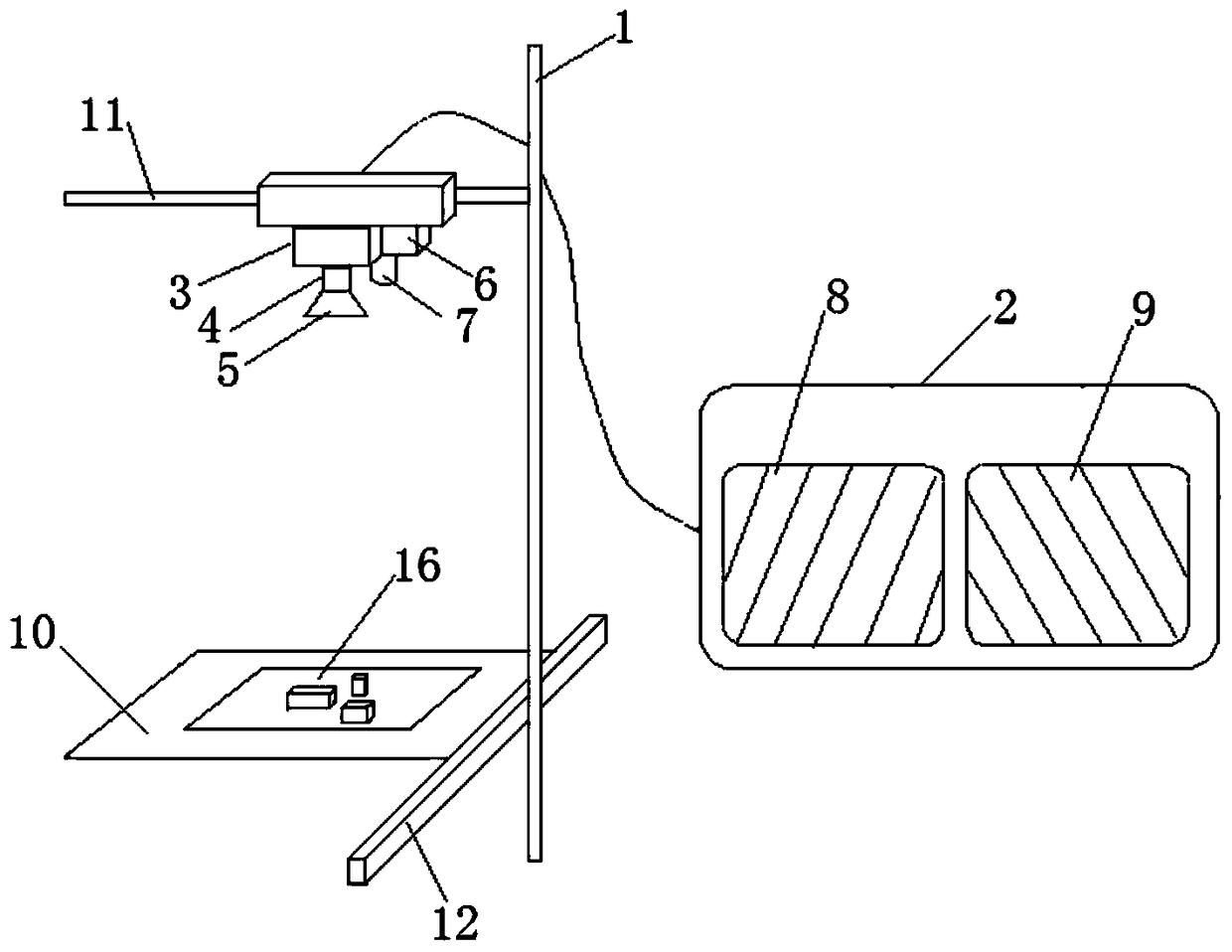

[0032] This embodiment provides an infrared detection device for automatically positioning and detecting a position, such as figure 1 shown, which includes,

[0033] Adjustable support 1, the adjustable support is an X-Y direction adjustment support, which is composed of an upper support 11 located at the top and a lower support 12 located at the lower part; the upper support 11 and the lower support 12 move along the horizontal plane, and the moving directions are mutually Vertical; the lower part of the adjustable support 1 is provided with a stage 10, and the sample 16 to be tested is placed on the stage 10;

[0034] The upper bracket 11 of the adjustable bracket 1 is connected with a visible light shooting device and an infrared light detection device; the visible light shooting device is composed of a visible light camera 3, a visible light lens 4 and a visible light light source 5 arranged on the visible light camera 3, The infrared light detection device is made up of ...

Embodiment 2

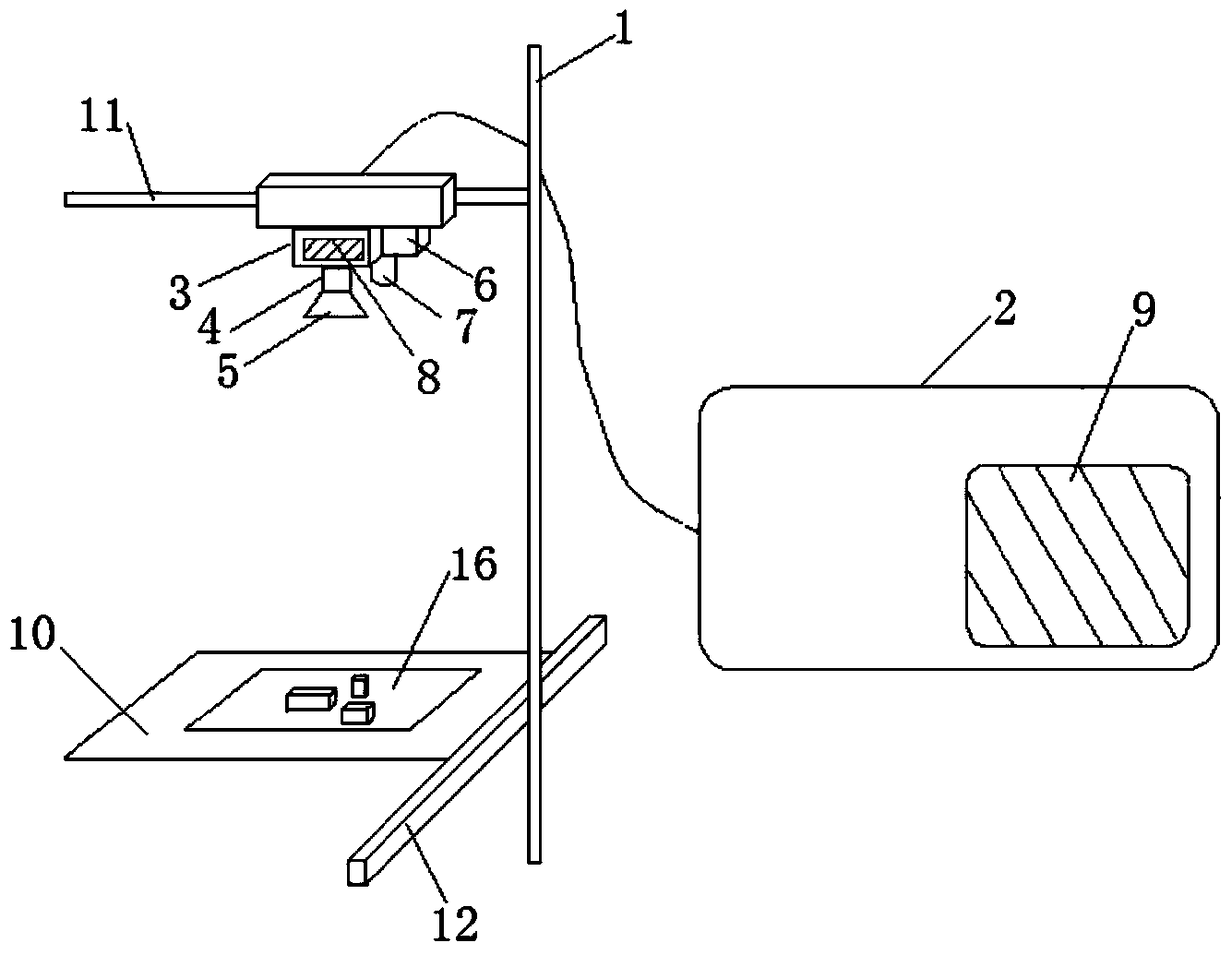

[0044] This embodiment provides an infrared detection device for automatically positioning and detecting a position, such as image 3 As shown, this embodiment is substantially the same as Embodiment 1, except that the positioning chip 8 integrated with visible light positioning software is set in the visible light camera 3, and the detection chip 9 integrated with infrared light detection software is set in the described In the control device 2.

Embodiment 3

[0046] This embodiment provides an infrared detection device for automatically positioning and detecting a position, such as Figure 4 As shown, this embodiment is substantially the same as Embodiment 1 and Embodiment 2, except that the positioning chip 8 integrated with visible light positioning software is arranged in the visible light camera 3, and the detection chip 9 integrated with infrared light detection software Set in the infrared camera 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com