Sealing method of aviation casting machine box cavity pressure test

A cavity pressure and casing technology, applied in the direction of using stable tension/pressure to test the strength of materials, using liquid/vacuum for liquid tightness measurement, measuring devices, etc. Inner cavity sealing, kerosene leakage and other problems, to achieve the effect of low manufacturing cost, improved production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

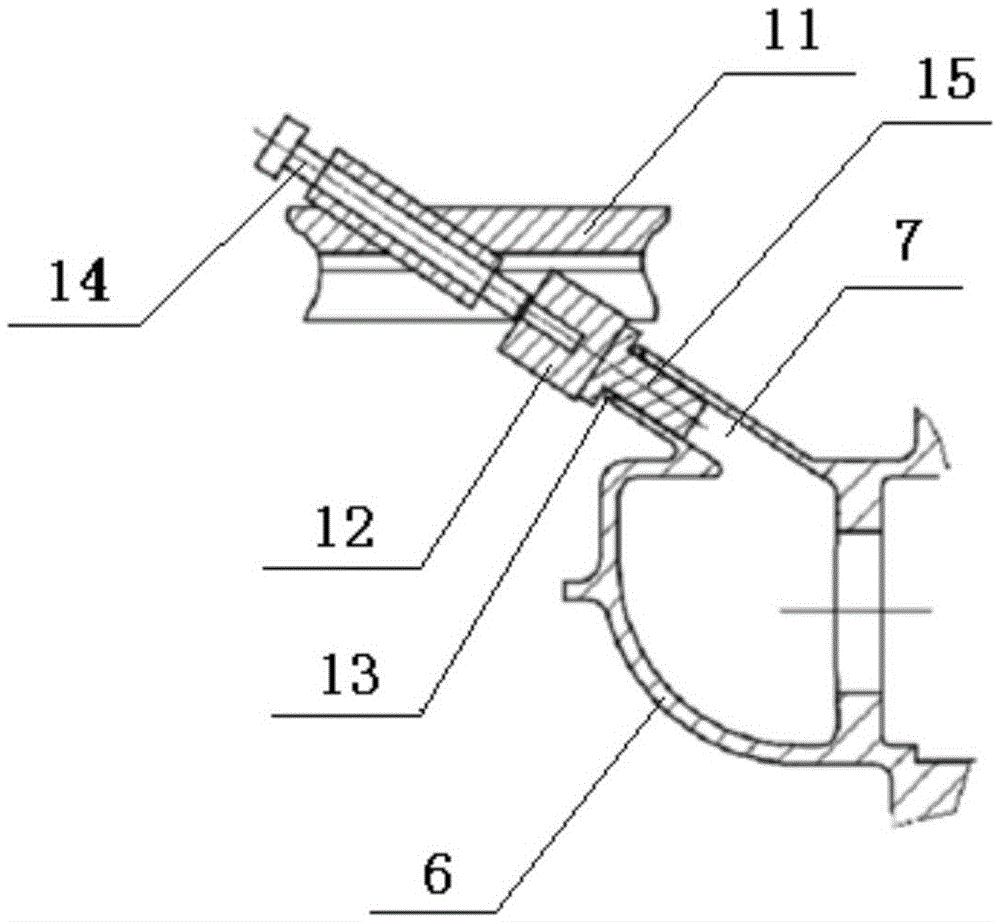

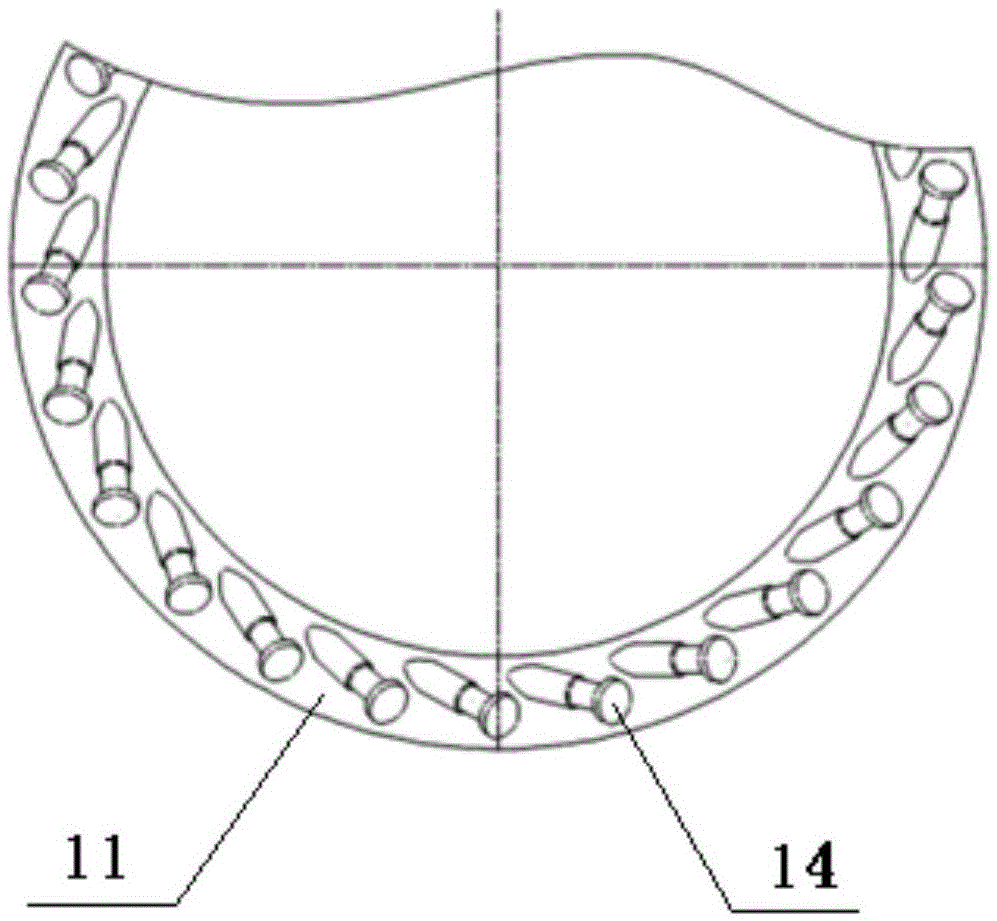

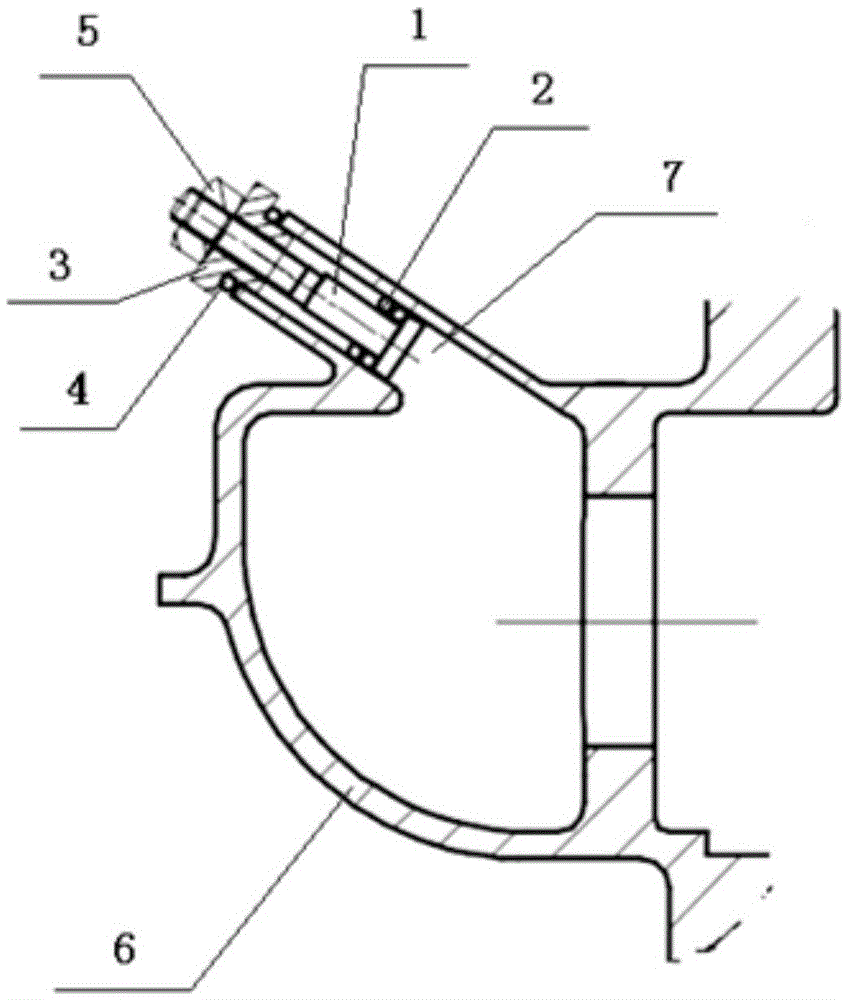

[0019] like image 3 , 4 As shown, a sealing method for aviation casting casing cavity pressure test, the aviation casting casing cavity 6 has a plurality of light holes 7, when the cavity pressure test is performed, the light holes 7 are sealed, and the following process is implemented:

[0020] 1. Make the end of the adjusting bolt 1 cylindrical, and its outer circle diameter is 0.1mm smaller than the minimum nominal size of the light hole diameter; choose two O-shaped rubber sealing rings 12, and its outer circle diameter 0.6mm larger than the maximum nominal size of the diameter of the light hole; put the O-shaped rubber sealing ring 1 on the adjusting bolt 1, and then put the O-shaped rubber sealing ring 1 and the adjusting bolt 1 into the light hole 7 ; It can make up for the aperture tolerance of 0.5mm in different depth sections of the light hole 7, and play a role in radial sealing of the light hole 7;

[0021] 2. The plug 3 is provided with an inner hole, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com