Ballscrew noise measuring method based on microphone array

A technology of ball screw pair and microphone array, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

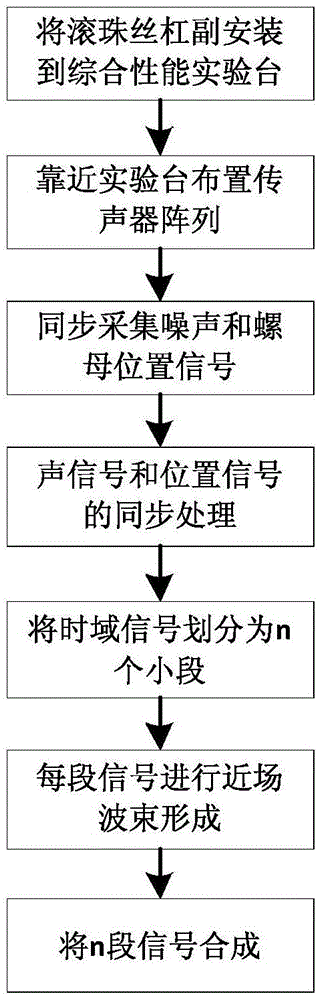

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

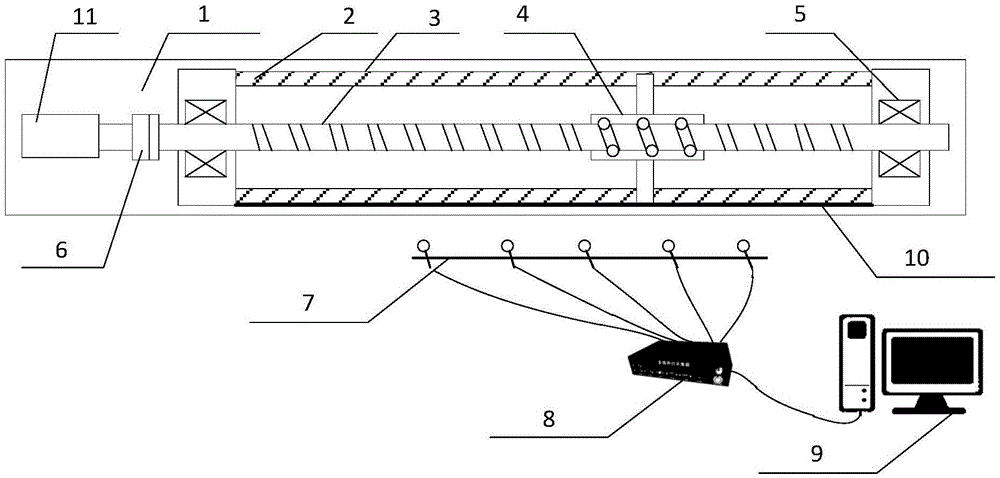

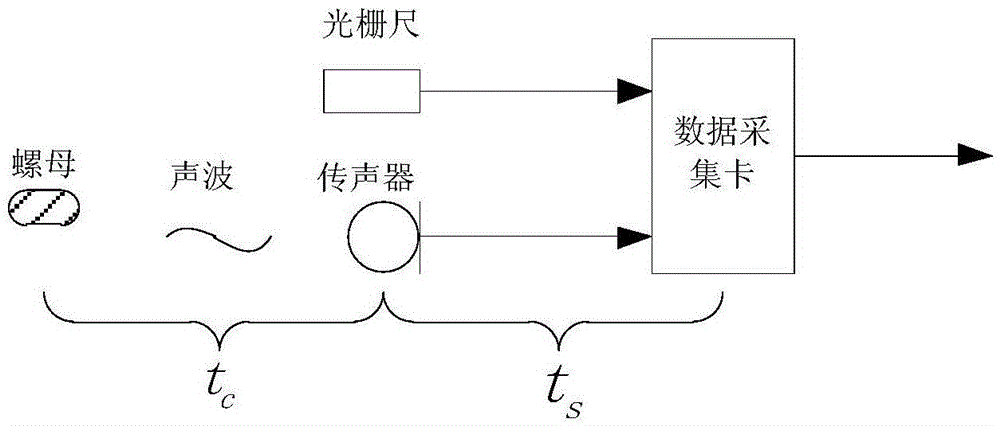

[0046] Such as figure 2As shown, 1 is the base of the test bench, 2 is the guide rail, 3 is the ball screw, 4 is the nut, 5 is the support bearing, 6 is the coupling, 7 is the microphone array, 8 is the data collector, 9 is the computer, 10 is a grating ruler, and 11 is a servo motor. The ball screw pair is installed on the comprehensive performance test bench, and M microphones form a uniform linear array, which is placed on one side of the test bench, parallel to the lead screw. The height of the microphone array is consistent with the nut, or slightly higher than the nut. The microphone array picks up the sound signal, and the grating ruler collects the position information of the nut, the sound-producing part of the ball screw pair. The main sources of interference at the noise measurement site are the noise of the servo motor and the noise of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com