Preparing method of styrene-acrylate latex and styrene-acrylate latex

A technology of styrene-acrylic latex and emulsion, which is applied in the field of artificial latex chemical manufacturing, can solve the problems of large particle size distribution range and uneven molecular weight, and achieve the effect of ensuring stirring time, ensuring uniformity, and uniform material and temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

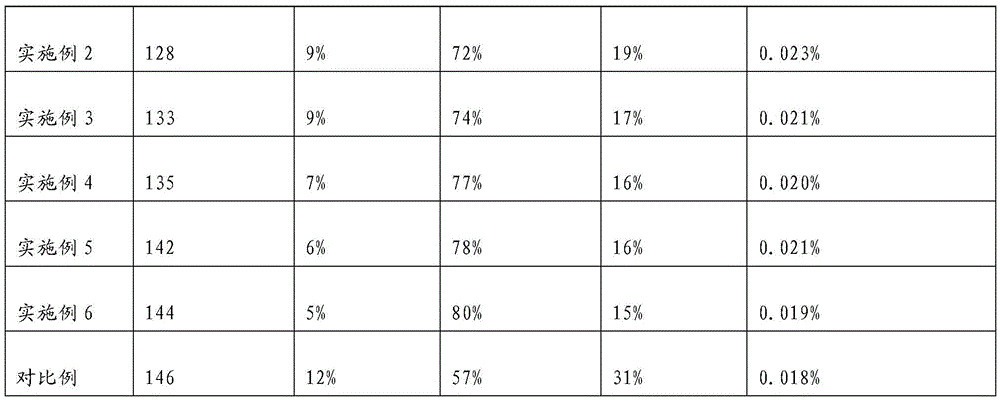

Examples

Embodiment 1

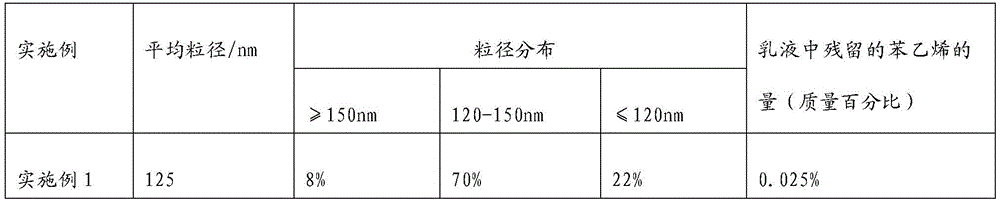

[0031] The present embodiment provides a kind of preparation method of styrene-acrylic latex:

[0032] The following raw materials are used: in parts by mass, including: in terms of 100 parts of polymerized monomers, 1 part of emulsifier, 70 parts of deionized water, 0.3 parts of molecular weight regulator, 0.6 parts of initiator, and 1.2 parts of seed emulsion;

[0033] The polymerized monomers are 30 parts of acrylate, 62 parts of styrene, and 8 parts of acrylic acid;

[0034] Include the following steps:

[0035] S1: Mix 35% deionized water, 15% initiator, 20% emulsifier and 50% polymerized monomer to obtain a prefabricated emulsion;

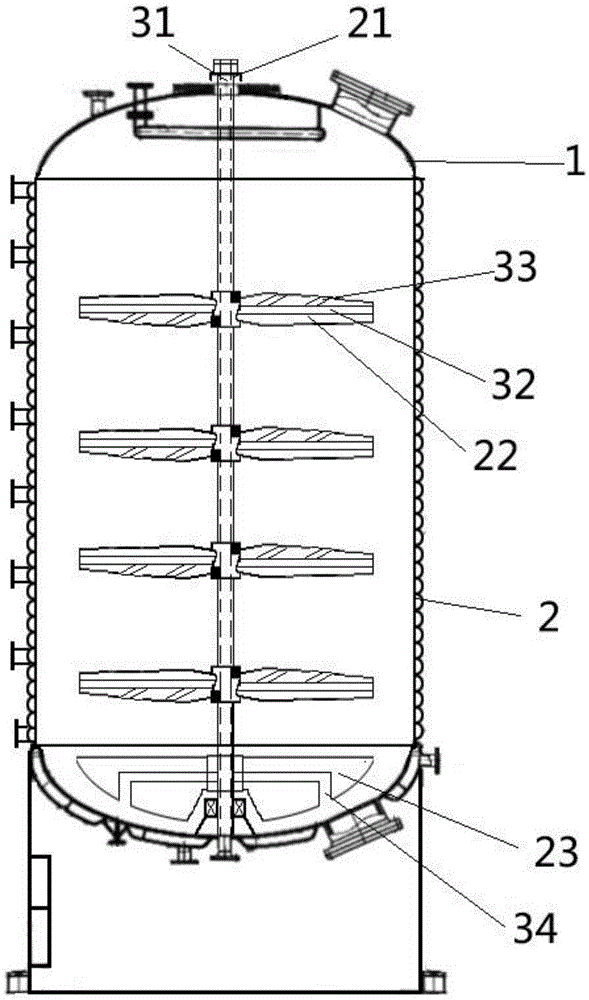

[0036] S2: Add the seed emulsion, the remaining initiator, the remaining emulsifier, the remaining mixed monomers and the remaining deionized water into the reaction vessel under vacuum conditions, and feed N into the reaction vessel during the adding process 2 , N 2 The feeding amount is 40kg / h, the flow rate is 10m / s, and the rotating sp...

Embodiment 2

[0041] The present embodiment provides a kind of preparation method of styrene-acrylic latex:

[0042] The following raw materials are used: in parts by mass, including: in terms of 100 parts of polymerized monomers, 1 part of emulsifier, 75 parts of deionized water, 0.4 parts of molecular weight regulator, 0.8 parts of initiator, and 1.4 parts of seed emulsion;

[0043] The polymerized monomers are 35 parts of acrylate, 59 parts of styrene, and 6 parts of acrylic acid;

[0044] Include the following steps:

[0045] S1: Mix 40% deionized water, 20% initiator, 25% emulsifier and 55% polymerized monomer to obtain a prefabricated emulsion;

[0046] S2: Add the seed emulsion, the remaining initiator, the remaining emulsifier, the remaining mixed monomers and the remaining deionized water into the reaction vessel under vacuum conditions, and feed N into the reaction vessel during the adding process2 , N 2 The feeding amount is 45kg / h, the flow rate is 15m / s, and the rotating spee...

Embodiment 3

[0051] The present embodiment provides a kind of preparation method of styrene-acrylic latex:

[0052] The following raw materials are used: in parts by mass, including: in terms of 100 parts of polymerized monomers, 1.5 parts of emulsifier, 80 parts of deionized water, 0.5 parts of molecular weight regulator, 1 part of initiator, and 1.6 parts of seed emulsion;

[0053] The polymerized monomers are 42 parts of acrylate, 53 parts of styrene, and 5 parts of acrylic acid;

[0054] Include the following steps:

[0055] S1: Mix 42% deionized water, 24% initiator, 28% emulsifier and 60% polymerized monomer to obtain a prefabricated emulsion;

[0056] S2: Add the seed emulsion, the remaining initiator, the remaining emulsifier, the remaining mixed monomers and the remaining deionized water into the reaction vessel under vacuum conditions, and feed N into the reaction vessel during the adding process 2 , N 2 The feeding amount is 48kg / h, the flow rate is 18m / s, and the rotating sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com