Efficient machining production device

A production equipment and machining technology, applied in the field of efficient parts machining production equipment, can solve the problems of rising production costs, increasing energy, affecting production capacity, etc., to achieve continuous and uninterrupted operation, improve production efficiency, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Feature and advantage of the present invention are described in detail as follows in conjunction with accompanying drawing:

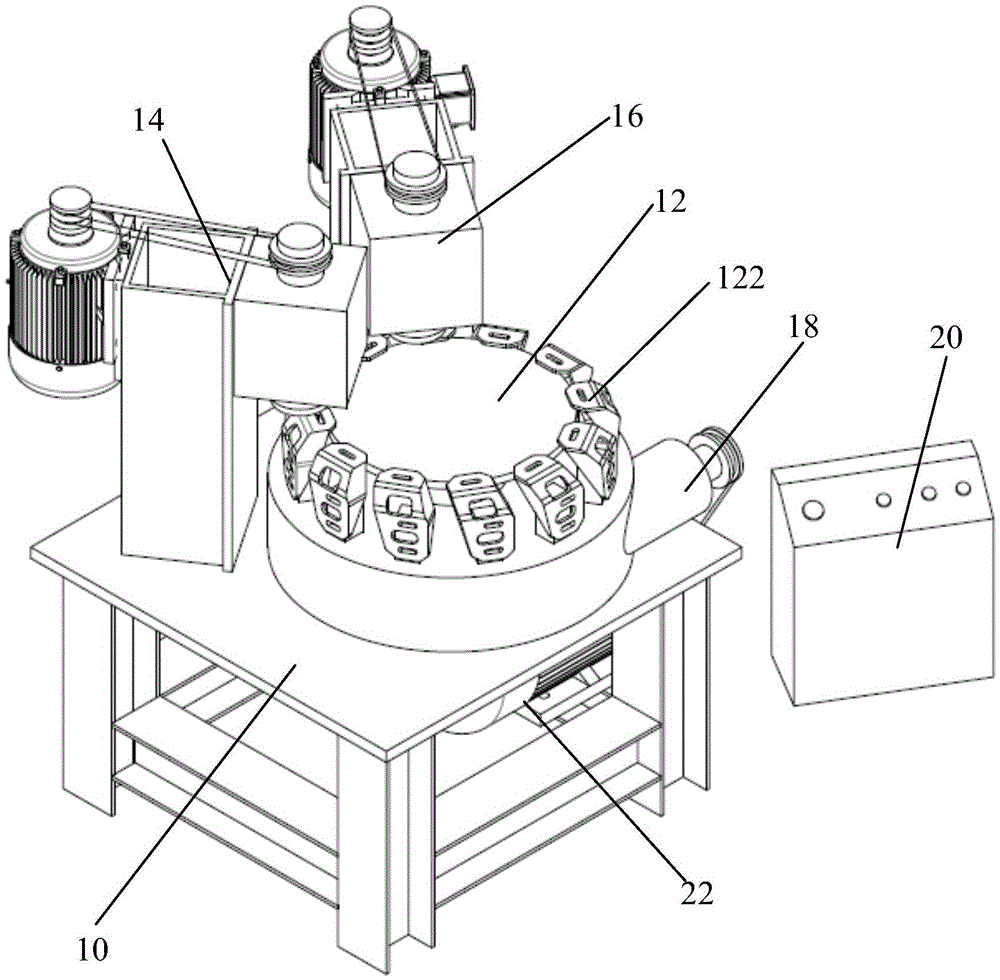

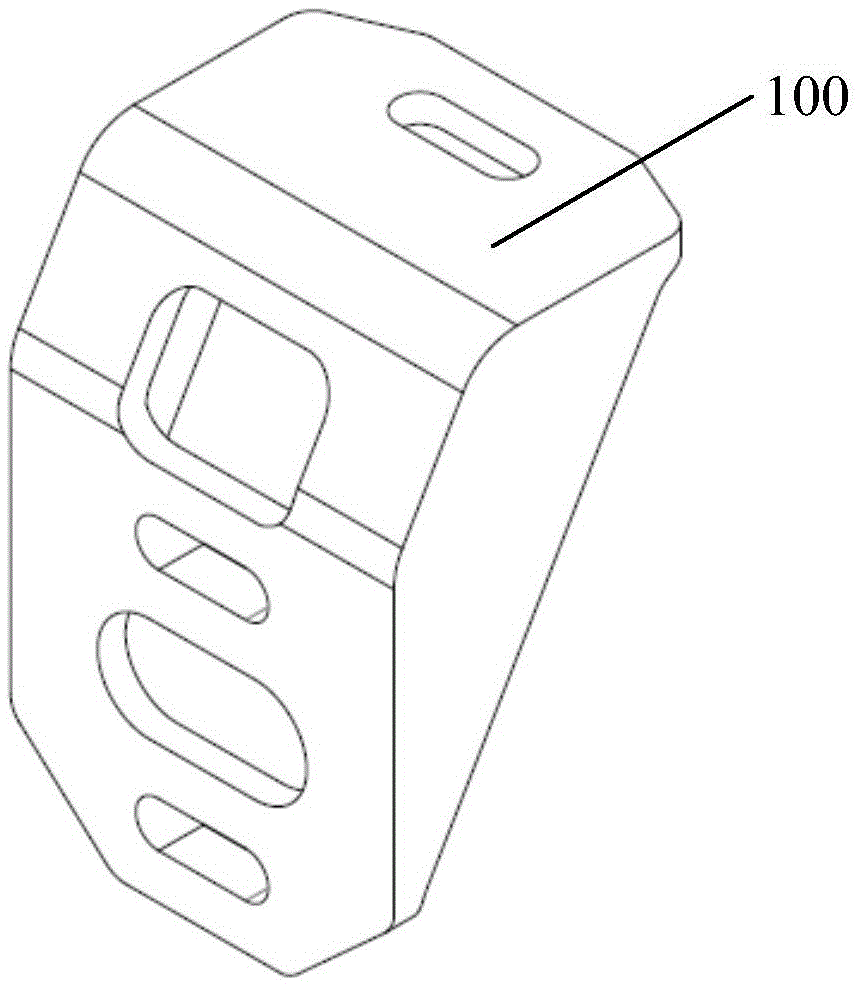

[0013] refer to figure 1 Shown is a schematic diagram of the composition and structure of a high-efficiency machining production equipment according to an embodiment of the present invention, which is used for processing parts 100. The high-efficiency machining production equipment includes an equipment base 10 on which a working round table 12 is fixed And operating equipment 14,16, stepping motor 22 and equipment control box 20, the operating tool head of described operating equipment 14,16 faces the processing station on the operating round table 12, and workpiece is processed simultaneously, described The operating round table 12 is provided with a plurality of workpiece fixing structures 122 along the circumferential direction, and the operating round table 12 is connected with the stepping motor 22 through the connecting mechanism 18. Driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com