Multi-sectional hydrogenation dehydrogenation furnace and manufacturing method of low-oxygen-content titanium powder

A hydrodehydrogenation, multi-stage technology, which is applied in the multi-stage hydrodehydrogenation furnace and the preparation of titanium powder with low oxygen content, can solve the problems of decreased mechanical properties, limited application of titanium powder, poor mechanical properties, etc., and achieves reduction in activation treatment. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

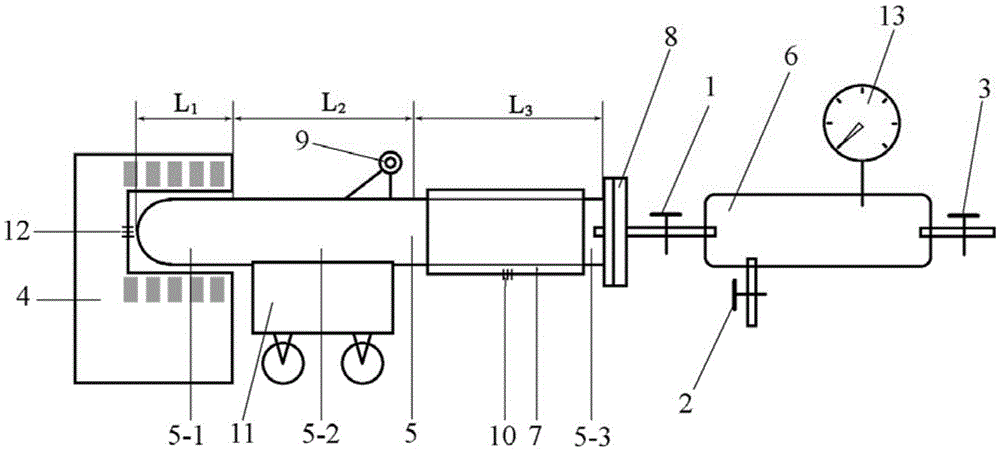

[0036] In this embodiment, the structural diagram of the multi-stage hydrodehydrogenation furnace is shown in figure 1 , including a horizontally placed heating furnace 4, a horizontally placed reactor 5, a gas storage tank 6, a cooling device 7 and a mobile support 11,

[0037] The reactor 5 is a cylinder with both ends closed, which is formed by connecting a heating section 5-1, an intermediate section 5-2 and a cooling section 5-3 in sequence, and the length of the heating section is L 1 : Length L of the middle section 2 : Length L of the cooling section 3 =1:4.5:4.5, the end of the cooling section is provided with a material inlet and outlet, the material inlet and outlet is provided with a sealing cover 8, the sealing cover 8 is provided with a gas inlet and outlet, and the cylinder is also provided with a hanging The hook 9 is used to cooperate with an external crane to change the placement posture of the reactor; the cooling device 7 is a water cooling jacket, and th...

Embodiment 2

[0040] In this embodiment, the structural diagram of the multi-stage hydrodehydrogenation furnace is shown in figure 1 , including a horizontally placed heating furnace 4, a horizontally placed reactor 5, a gas storage tank 6, a cooling device 7 and a mobile support 11,

[0041] The reactor 5 is a cylinder with both ends closed, which is formed by connecting a heating section 5-1, an intermediate section 5-2 and a cooling section 5-3 in sequence, and the length of the heating section is L 1 : Length L of the middle section 2 : Length L of the cooling section 3 =2:4:4, the end of the cooling section is provided with a material inlet and outlet, the material inlet and outlet is provided with a sealing cover 8, the sealing cover 8 is provided with a gas inlet and outlet, and the cylinder is also provided with a hanging Hook 9 is used to cooperate with an external crane to change the placement posture of the reactor; the cooling device 7 is composed of a fan and an aluminum cool...

Embodiment 3

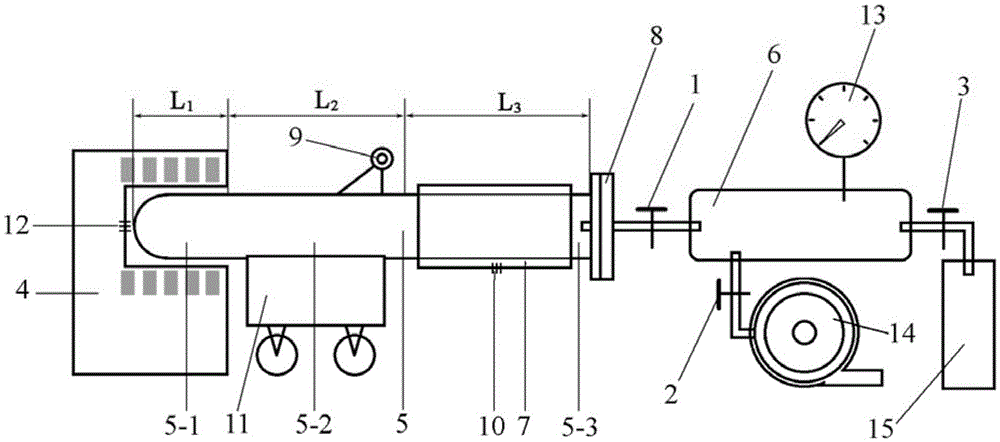

[0044] This embodiment provides the preparation method of titanium powder with low oxygen content, the method uses the multi-stage hydrodehydrogenation furnace described in Example 1, and is equipped with a vacuum pump 14 and a storage tank 15 storing high-purity hydrogen, and the vacuum pump and storing high-purity hydrogen The pure hydrogen storage tank is respectively connected with the vacuum joint and the hydrogen source joint of the gas storage tank 6 of the multi-stage hydrodehydrogenation furnace through pipe fittings, and the steps are as follows:

[0045] ① Loading, vacuuming and impurity removal

[0046] The sponge titanium used in this embodiment is grade 0 sponge titanium with a particle size not exceeding 25mm, and the sponge titanium is placed in the heating section 5-1 and the cooling section 5-3 of the reactor respectively, and the cooling section and the heating section The mass ratio of the titanium sponge in the container is 5:1, close the sealing cover 8 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com