MOS transistor and manufacturing method therefor

A technology of a MOS transistor and a manufacturing method, which are applied to the field of MOS transistors and their manufacturing, can solve the problems of slow carrier migration rate of MOS transistors, and achieve the effect of improving the carrier migration rate and the carrier migration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

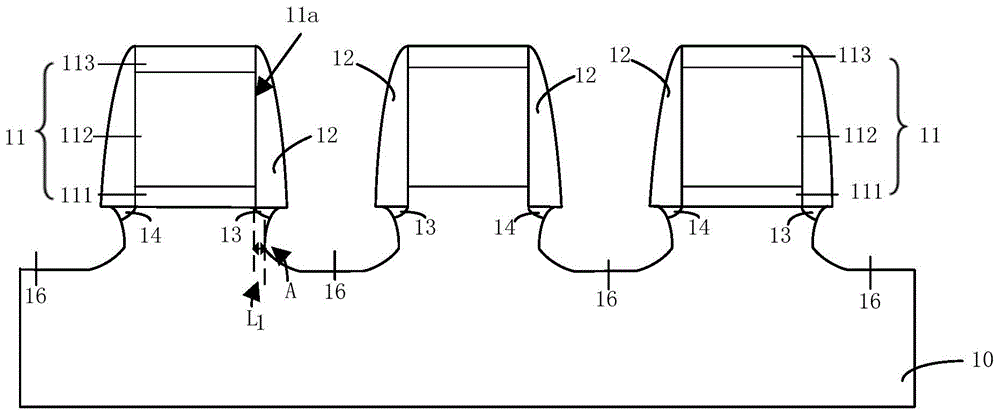

[0044] As mentioned in the background technology, the carrier mobility rate of existing embedded MOS transistors is still relatively slow. To solve the above problems, the present invention increases the amount of compressive stress material or tensile stress material filled in the source and drain regions. , thereby increasing the tensile or compressive stress applied to the channel. Specifically, by enlarging the size of the opening of the bowl-shaped groove that is scheduled to form the source and drain regions, making it larger than the distance between adjacent side walls, and then making the size of the opening of the sigma-shaped groove formed later also larger .

[0045] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

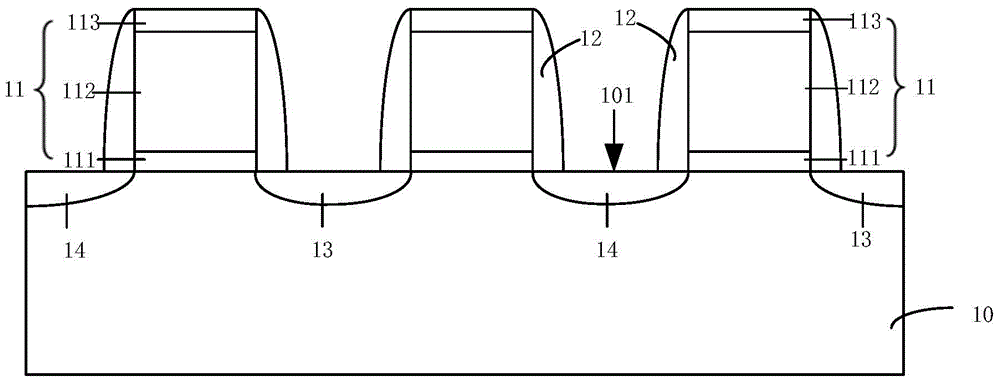

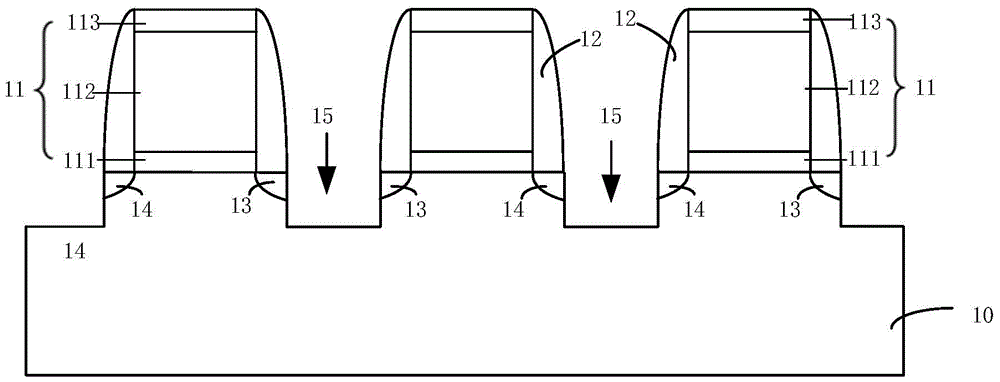

[0046] Figure 1 to Figure 4 is a cross-sectional view of a PMOS tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com