Touch-sensitive element and touch display device

A technology of touch sensing element and touch display device, which is applied in the direction of instrument, electrical digital data processing, input/output process of data processing, etc. The pixel aperture ratio of the device can be improved to improve the image quality and visual effect, improve the aperture ratio and reduce the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

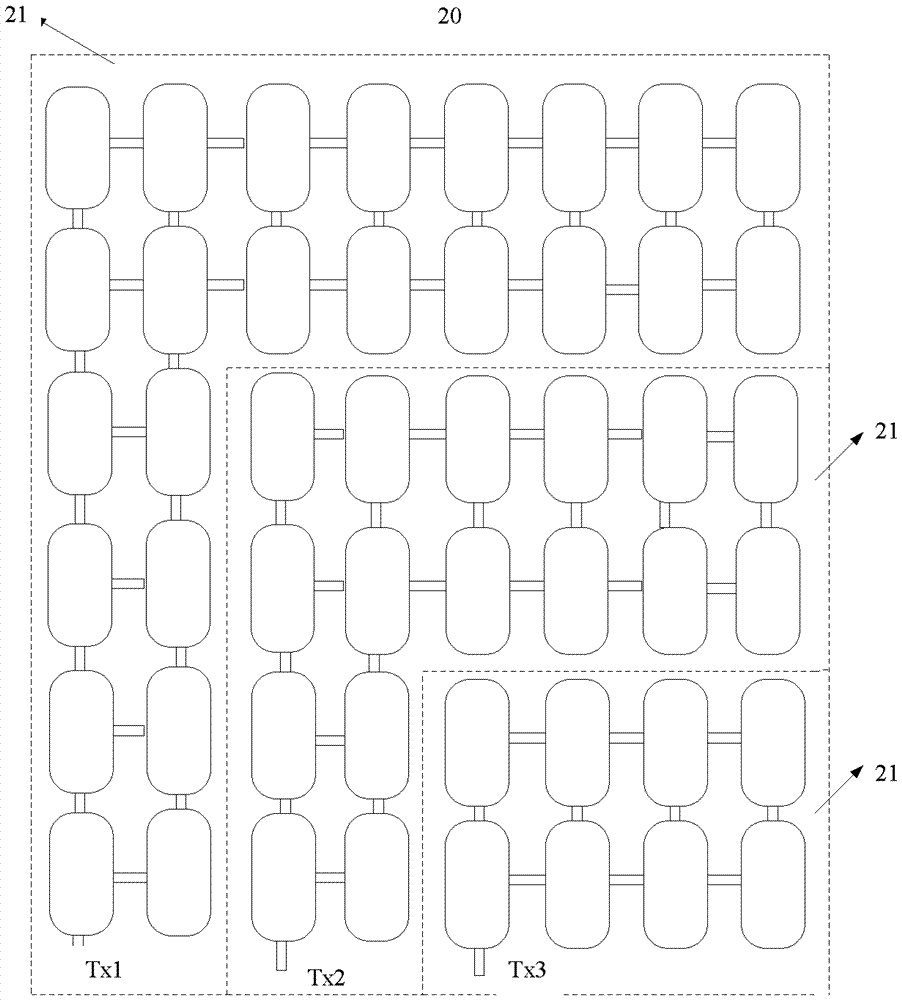

[0031] figure 2 The pattern of one touch sensing unit 10 in the touch sensing element according to one embodiment of the present invention is schematically shown, and it should be understood that the touch sensing element provided in this embodiment may include multiple such arrangements on the same layer of the touch sensing unit 10, in other words, figure 2 The touch sensing unit 10 shown in is just a repeating unit in the touch sensing element. In this embodiment, the touch-sensing element may include a plurality of touch-sensing units 10 arranged on the same layer, the touch-sensing unit 10 includes at least one first touch-sensing sub-unit 11, each first touch-sensing sub-unit 11 includes a first electrode The block array, the first electrode block array of the first touch sensing sub-unit 11 , is composed of a plurality of cascaded electrode blocks arranged on the same layer.

[0032] For clarity and simplicity, figure 2 Only three first touch sensing subunits 11 a...

Embodiment 2

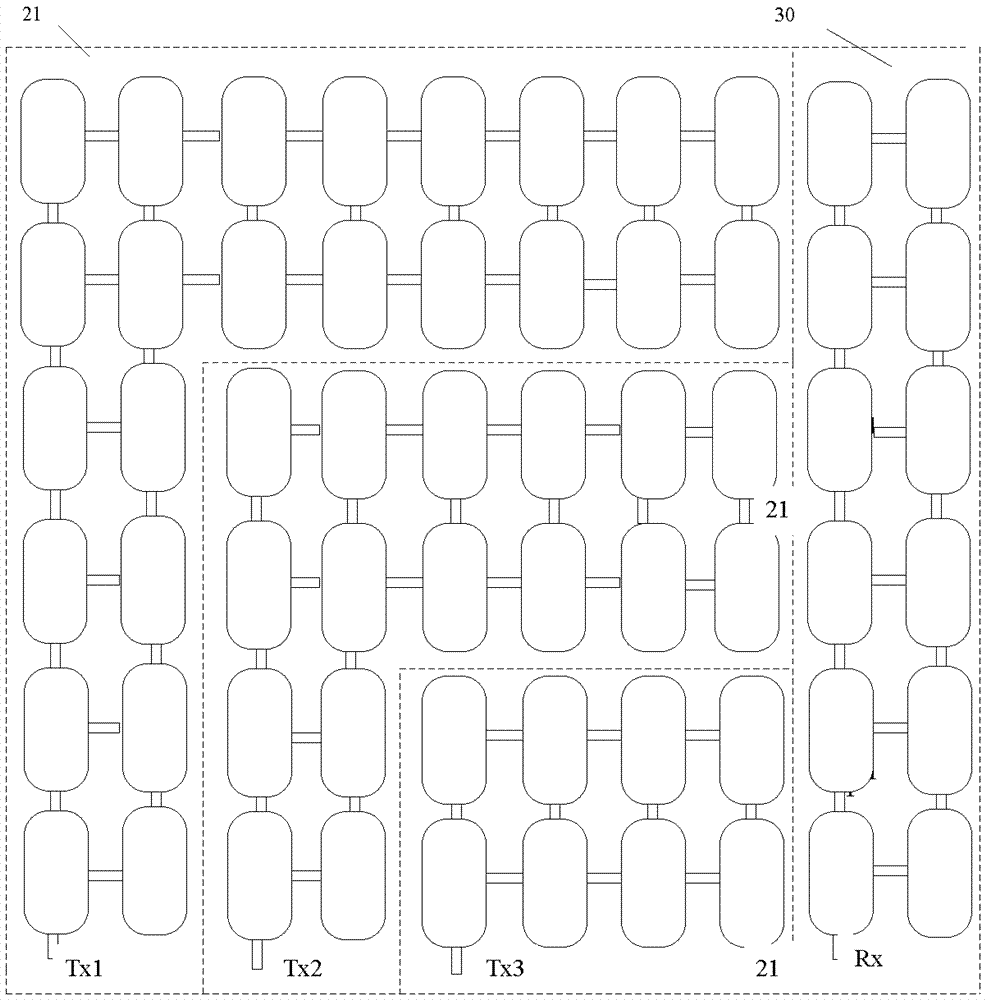

[0038] see Figure 5 , which schematically shows a touch sensing element according to another embodiment of the present invention. On the basis of Embodiment 1, a second touch sensing subunit 30 is added. The second touch sensing subunit includes a second electrode block array composed of a plurality of cascaded electrode blocks arranged on the same layer, and the second touch The sensing subunit is insulated from the first touch sensing subunit.

[0039] divide and figure 2 In addition to the same or similar structures, the structure of this embodiment with the addition of the second touch sensing sub-unit 30 can provide a structural basis for realizing mutual capacitive touch. Wherein each first touch sensing sub-unit 11 can be used as a drive electrode receiving drive signals Tx1, Tx2, Tx3 from the touch detection chip, and the second touch sensing sub-unit 30 can be used to provide sensing for the touch detection chip. Sensing electrode for signal Rx. As known to thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com