Polylactic acid composite material

A composite material and polylactic acid technology, applied in the field of preparation of polylactic acid composite materials, can solve the problems of poor toughness and high brittleness of polylactic acid materials, and achieve the effects of improving compatibility, toughness and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

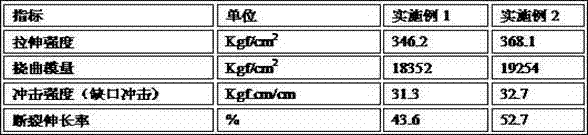

specific Embodiment 1

[0030] A kind of polylactic acid composite material, comprises the combination of following material and consumption:

[0031] Polylactic acid: 100 parts

[0032] Polylactic acid grafted glycidyl methacrylate: 24 parts

[0033] Starch grafted polylactic acid: 22 parts

[0034] Acetate nanocellulose: 13 parts

[0035] Cellulose acetate propionate: 12 parts

[0036] Antioxidant: 2.5 parts

[0037] It is also characterized in that it is prepared by the following process, and the process is:

[0038] A: Vacuum dry all raw materials at 60 degrees for 5 hours, and set aside;

[0039] B: Disperse cellulose acetate nanocellulose and cellulose acetate propionate in a mixed solution of ethanol and water with a mass ratio of 1:3, and then blend them in a high-speed blender at 50 degrees for 10 minutes at a speed of The temperature is 50rad / min, and then put into the extruder to melt and extrude, the temperature is 180-200 degrees, the extrusion time is 2 minutes, the speed is 80rad...

specific Embodiment 2

[0049] A kind of polylactic acid composite material, comprises the combination of following material and consumption:

[0050] Polylactic acid: 100 parts

[0051] Polylactic acid grafted glycidyl methacrylate: 32 parts

[0052] Starch grafted polylactic acid: 26 parts

[0053] Acetate nanocellulose: 10 parts

[0054] Cellulose acetate propionate: 15 parts

[0055] Antioxidant: 3 parts

[0056] It is also characterized in that it is prepared by the following process, and the process is:

[0057] A: Vacuum dry all raw materials at 60 degrees for 5 hours, and set aside;

[0058] B: Disperse acetic acidified nanocellulose and cellulose acetate propionate in a mixed solution of ethanol and water with a mass ratio of 1:3, and then blend them in a high-speed blender at 50 degrees for 10 minutes. The temperature is 50rad / min, and then put into the extruder to melt and extrude, the temperature is 180-200 degrees, the extrusion time is 2 minutes, the speed is 80rad / min, extrude an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com