Elution device and separation method for nitric acid type tin stripping waste liquid

A separation method and tin stripping technology, applied in chemical instruments and methods, metallurgical wastewater treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as secondary pollution and low efficiency of distillation physical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

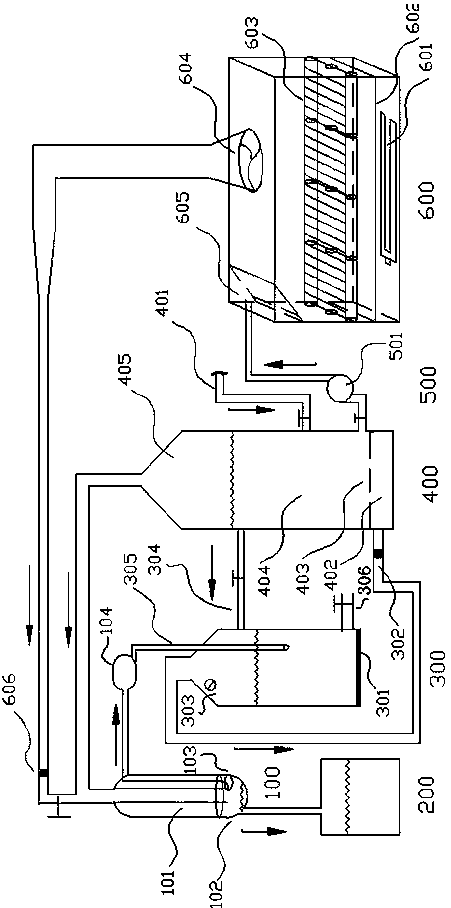

[0034] See figure 1 , A nitric acid type tin stripping waste liquid elution device includes a constant temperature condensation fractionator 100, a collection tank 200, a constant temperature distiller 300, an elution tank 400 and a dry fluidized bed 600.

[0035] The thermostatic distiller 300 is provided with an eluent inlet 303, a heater 301, a vapor outlet, and a liquid outlet 306 at the lower part.

[0036] The elution tank 400 is provided with a porous carrier plate 403. The porous carrier separates the interior of the elution tank 400 into a vapor buffer chamber 402 and an elution chamber 404. The vapor buffer chamber 402 is located at the lower part of the elution tank 400 and is connected to the thermostatic still 300. The elution chamber 404 is located above the porous carrier plate 403, the elution chamber 404 is provided with a waste liquid inlet 401, and the separation communication pipe 304 is provided between the elution chamber 404 and the thermostatic still 300, a...

Embodiment 2

[0055] The main technical solution of this embodiment is basically the same as that of Embodiment 1. For the features that are not explained in this embodiment, the explanation in Embodiment 1 is adopted, which will not be repeated here. A separation method of nitric acid type tin stripping waste liquid is as follows:

[0056] Open the injection port of the thermostatic distiller 300, fill the 200L thermostatic distiller 300 with ethanol eluent, and inject 100L of the nitric acid type tin stripping waste liquid into the sampling tube. The total tin content of the tin stripping waste liquid is 131.5g / L, Cu 2+ The concentration is 17.4g / L, start to heat the thermostatic still 300, control the temperature in the still to 85°C, so that ethanol vapor is injected into the elution tank 400 from the pipeline through the one-way valve piston 302, the hot vapor is the elution tank 400 After half an hour, the collection tank 200 began to produce droplets, and the liquid level of the connect...

Embodiment 3

[0059] The main technical solution of this embodiment is basically the same as that of Embodiment 1. For the features that are not explained in this embodiment, the explanation in Embodiment 1 is adopted, which will not be repeated here. A method for separating nitric acid type tin stripping waste liquid. In step (2), the temperature in the distiller is controlled to be 75°C, and the temperature of the lower part of the constant temperature condensation fractionator 100 is controlled to be 75°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com