Pneumatic material pushing device with side leakage prevention effect for solid-liquid separation and material collection

A technology of solid-liquid separation and pushing device, which is applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of increasing the load strength of driving equipment, weakening the degree of solid-liquid separation, low efficiency, etc., and achieve good air drying And wind resistance effect, improve the effect of solid-liquid separation, prevent clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

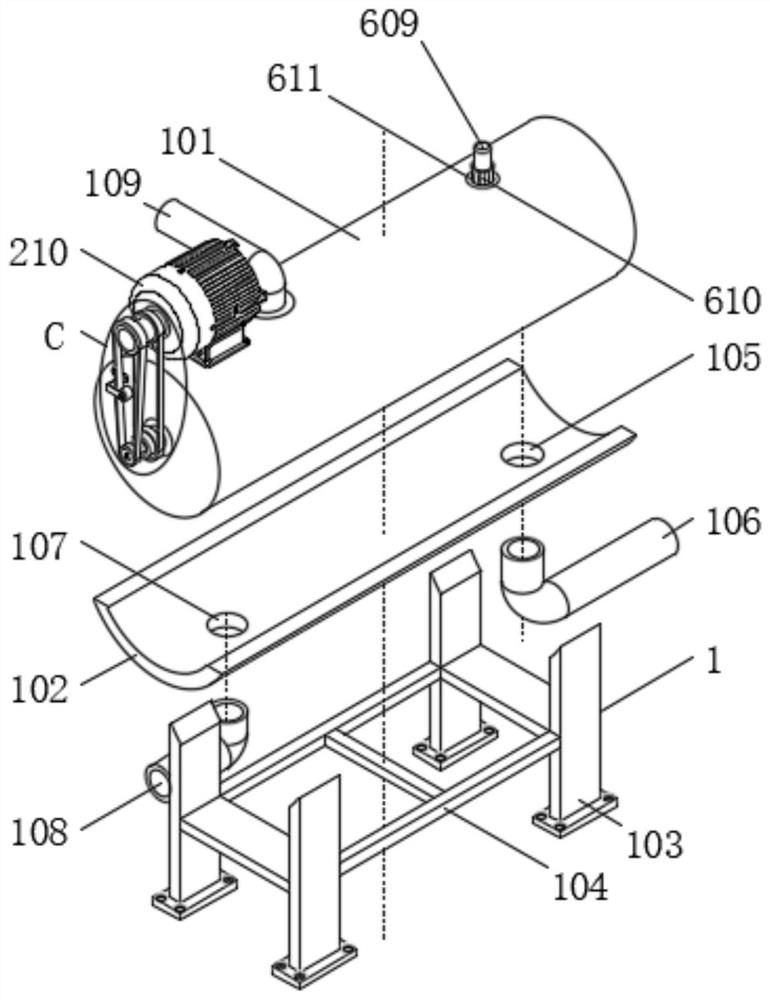

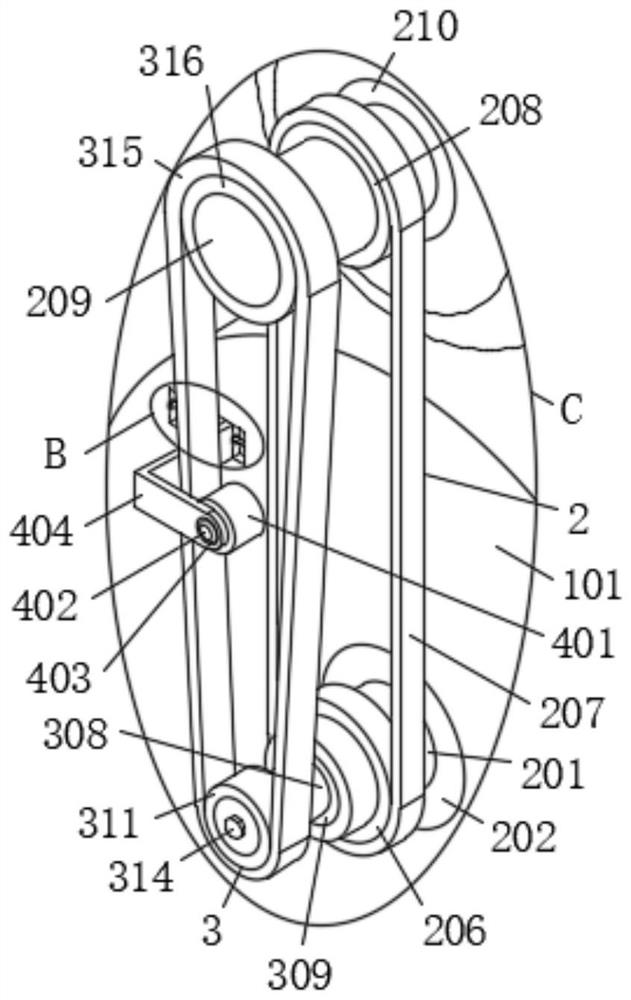

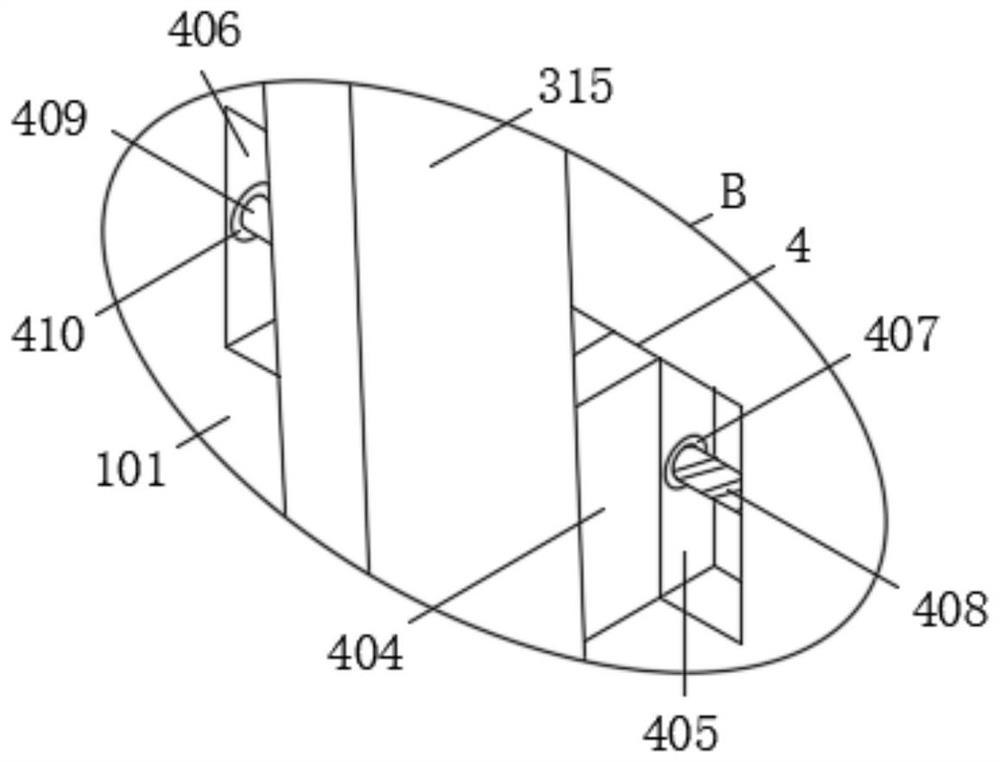

[0048] A pneumatic pushing device with side leakage prevention effect for solid-liquid separation and receiving, comprising a base component 1, a solid-liquid separation component 2 is fixedly connected to the inner end surface of the base component 1, and the solid-liquid separation component 2 is also clamped on the end surface inside the base assembly 1, and the bottom of the solid-liquid separation assembly 2 is also fixedly connected to the top of the base assembly 1 through a shock absorber, and the inside of the solid-liquid separation assembly 2 is sleeved with a pressure regulation assembly 3. The pressure regulation assembly 3 is also clamped on the end face inside the solid-liquid separation assembly 2, and the pressure regulation assembly 3 is also movably socketed on the surface of the solid-liquid separation assembly 2, and the surface of the pressure regulation assembly 3 is engaged with Tightness control component 4, the tightness control component 4 is arranged...

Embodiment 2

[0063] A pneumatic pushing device with side leakage prevention effect for solid-liquid separation and receiving, comprising a base component 1, a solid-liquid separation component 2 is fixedly connected to the inner end surface of the base component 1, and the solid-liquid separation component 2 is also clamped on the end surface inside the base assembly 1, and the bottom of the solid-liquid separation assembly 2 is also fixedly connected to the top of the base assembly 1 through a shock absorber, and the inside of the solid-liquid separation assembly 2 is sleeved with a pressure regulation assembly 3. The pressure regulation assembly 3 is also clamped on the end face inside the solid-liquid separation assembly 2, and the pressure regulation assembly 3 is also movably socketed on the surface of the solid-liquid separation assembly 2, and the surface of the pressure regulation assembly 3 is engaged with Tightness control component 4, the tightness control component 4 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com