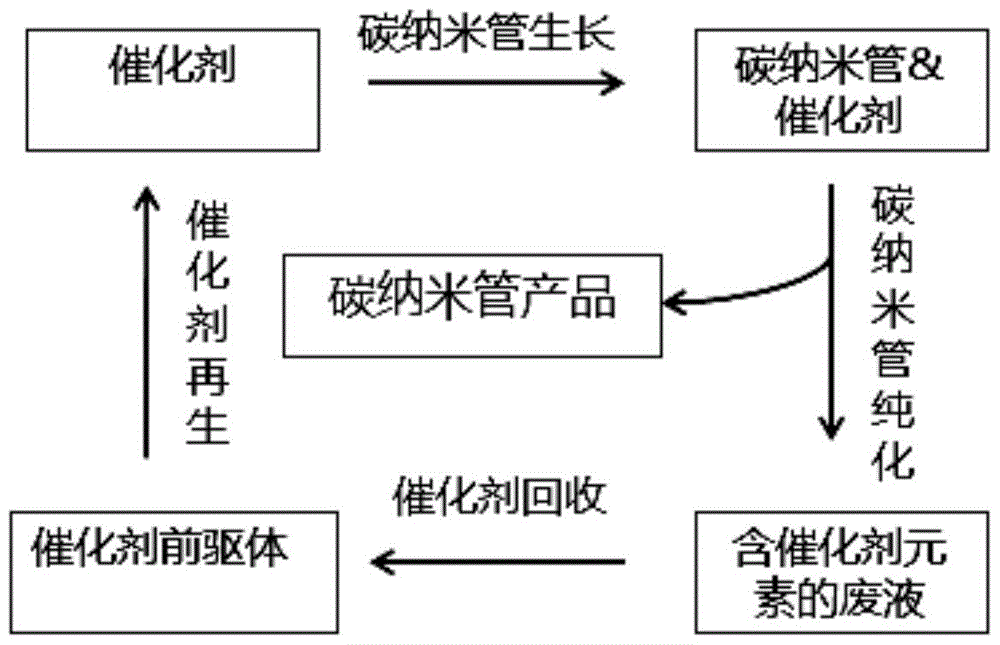

A method for self-recycling of carbon nanotube catalysts

A carbon nanotube and catalyst technology, applied in the field of carbon nanotube catalyst self-recycling, can solve problems such as pollution, material waste and environment, and achieve the effect of reducing waste liquid discharge and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

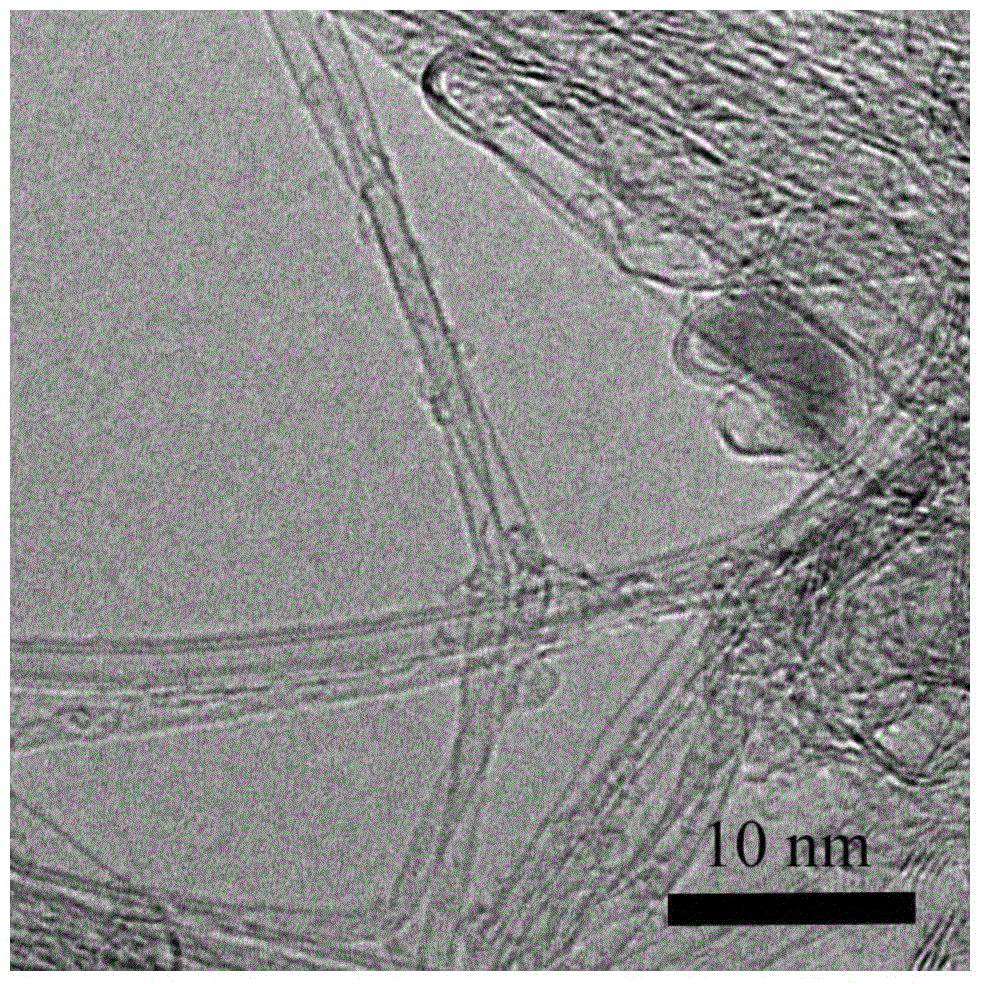

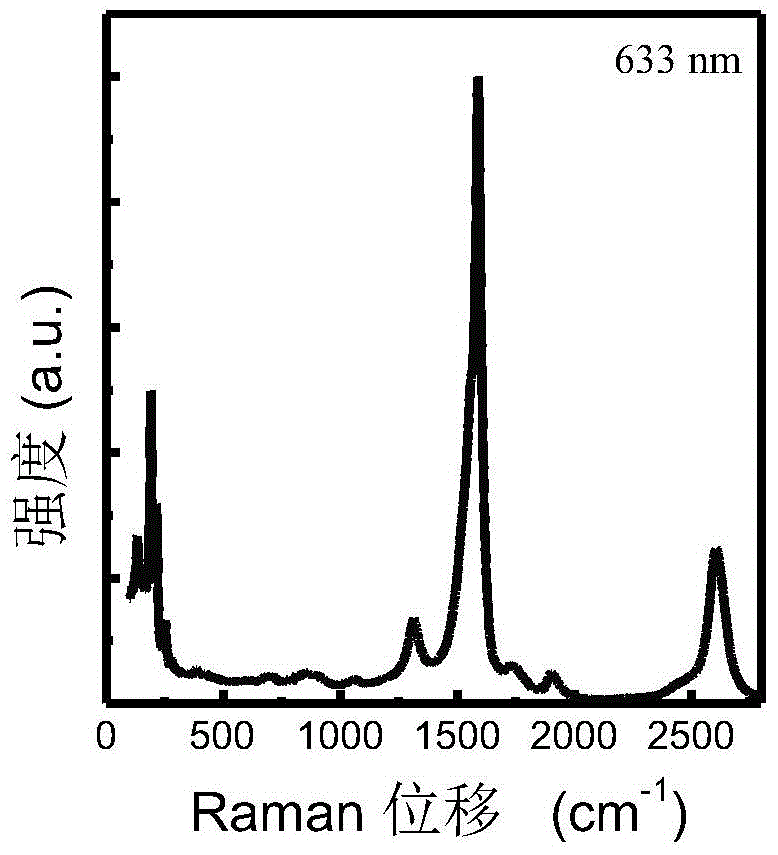

Embodiment 1

[0029] Fe is used as a catalyst active component, magnesium oxide is used as a catalyst carrier, and carbon nanotubes are prepared by chemical vapor deposition. Take 20kg and place it in a stirred tank, add 600L of 10% sulfuric acid solution by mass fraction, and process it under stirring for 12 hours, and the reaction temperature is maintained at 80°C. Separate by filtration to collect solid and liquid respectively. The solid is repeatedly rinsed, dried, and weakly oxidized to obtain a carbon nanotube product, which is packaged and preserved. The liquid is transported to the stirring tank of the catalyst recovery device, where 1 kg of ethylenediaminetetraacetic acid disodium salt is added to complex the iron ions in the solution, and 400 L of 2 mol / L ammonium carbonate solution is added to adjust the pH of the mixed solution to 8.5, and then The liquid-phase co-precipitation reaction was carried out at room temperature, and the reaction time was 2 hours. Liquid-solid separa...

Embodiment 2

[0031] Co is used as the catalyst active component, magnesium oxide is used as the catalyst carrier, and carbon nanotubes are prepared by chemical vapor deposition. Take 2 kg and place it in a stirred tank, add 30 L of sulfuric acid solution with a mass fraction of 20%, and process it under stirring for 2 hours, and the reaction temperature is maintained at 90°C. Separate by filtration to collect solid and liquid respectively. The solid is repeatedly rinsed, dried, and vacuumed at high temperature to obtain carbon nanotube products, which are packaged and preserved. The liquid is transported to the stirring tank of the catalyst recovery device, where 0.2kg of ethylenediaminetetraacetic acid disodium salt is added to complex the metal ions in the solution, and 8L of 10mol / L sodium hydroxide solution is added to adjust the pH of the mixed solution to 8.5 , carry out liquid-phase co-precipitation reaction at room temperature, and the reaction time is 6 hours. Liquid-solid separ...

Embodiment 3

[0033] Ni is used as a catalyst active component, magnesium oxide is used as a catalyst carrier, and carbon nanotubes are prepared by a chemical vapor deposition method. Take 200kg and place it in a stirred tank, add 1000L of nitric acid solution with a mass fraction of 40%, and process it under stirring for 24 hours, and the reaction temperature is maintained at 50°C. The solid and liquid were collected separately by centrifugation. The solid is repeatedly rinsed, dried, and weakly oxidized to obtain a carbon nanotube product, which is packaged and preserved. The liquid is transported to the stirring tank of the catalyst recovery device, where 2kg of ethylenediaminetetraacetic acid disodium salt is added to complex the metal ions in the solution, sodium carbonate solid is added, the pH of the mixed solution is adjusted to 8.5, and the liquid is carried out at room temperature. Phase co-precipitation reaction, the reaction time is 6 hours. Liquid-solid separation is carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com