Method and apparatus for production of electronic grade hydrogen gas

An electronic grade, hydrogen technology, applied in the direction of hydrogen separation, liquid contact hydrogen separation, solid contact hydrogen separation, etc., can solve the problem of polysilicon quality is harmful, polysilicon can not meet the requirements of electronic grade polysilicon, impurities can not be completely removed, etc. problem, to achieve the effect of high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

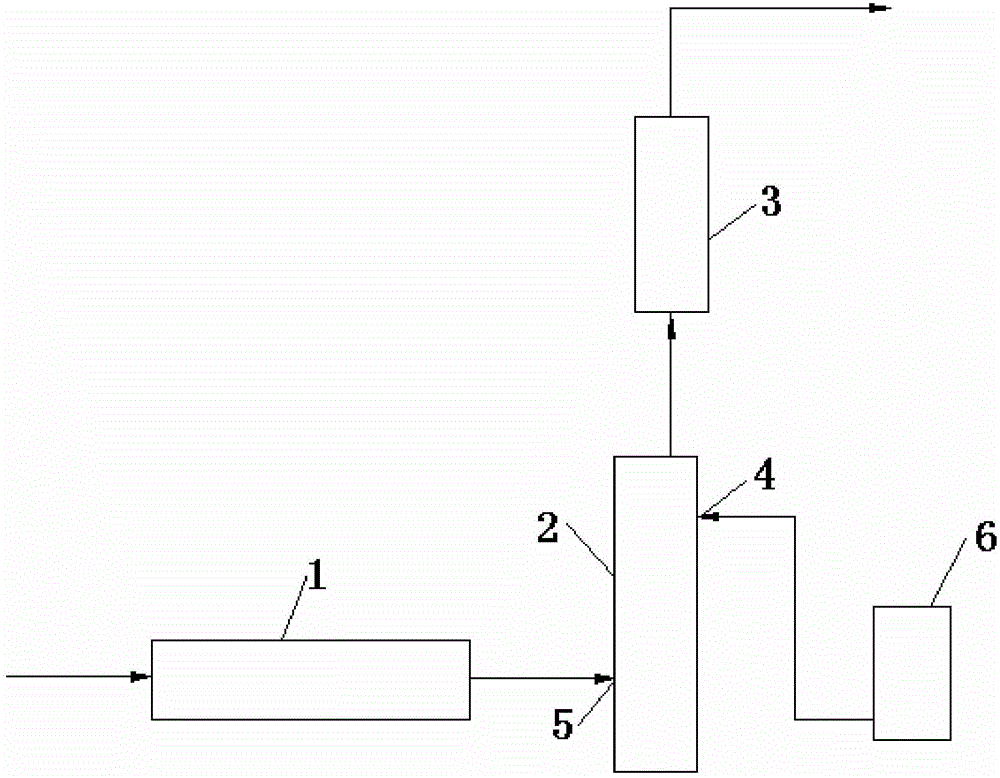

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for producing electronic-grade hydrogen, comprising the following steps:

[0026] (1) The hydrogen gas with a purity of 99.808-99.945% obtained after the tail gas in polysilicon production is processed is adsorbed by an activated carbon adsorbent.

[0027] The tail gas in polysilicon production is treated to obtain hydrogen with a purity of 99.808-99.945%, which contains hydrogen chloride, boron chloride, phosphorus chloride, phosphine, borane, carbon monoxide, carbon dioxide, methane, nitrogen, CH 3 BCl 2 , (CH3) 2 PH, (CH 3 ) 3 CCl and other impurities, if the hydrogen gas with a purity of 99.808-99.945% obtained after the tail gas in the polysilicon production is processed continues to be used in the polysilicon production, it is not conducive to the production of high-purity electronic-grade polysilicon.

[0028] The purity of the tail gas in the polysilicon production in step (1) obtained after treatment is 99.808% to 99.945%. ...

Embodiment 2

[0045] This embodiment provides a method for producing electronic-grade hydrogen, comprising the following steps:

[0046] (1) The hydrogen gas with a purity of 99.808% obtained after the tail gas in polysilicon production is processed is adsorbed by an activated carbon adsorbent.

[0047] The tail gas in polysilicon production is treated to obtain hydrogen with a purity of 99.808%, which contains hydrogen chloride, boron chloride, phosphorus chloride, phosphine, borane, carbon monoxide, carbon dioxide, methane, nitrogen, CH 3 BCl 2 , (CH3) 2 PH, (CH 3 ) 3 Impurities such as CCl, such as hydrogen gas with a purity of 99.808% obtained after the tail gas in polysilicon production is processed, will be harmful to the quality of polysilicon if it is continued to be used in polysilicon production.

[0048] The purity of the tail gas in the polysilicon production in step (1) obtained after treatment is 99.808% impurity content in hydrogen: wherein, the total volume content of hy...

Embodiment 3

[0065] This embodiment provides a method for producing electronic-grade hydrogen, comprising the following steps:

[0066] (1) The hydrogen gas with a purity of 99.945% obtained after the tail gas in polysilicon production is processed is adsorbed by an activated carbon adsorbent.

[0067] After the tail gas in polysilicon production is processed, the hydrogen gas with a purity of 99.945% contains hydrogen chloride, boron chloride, phosphorus chloride, phosphine, borane, carbon monoxide, carbon dioxide, methane, nitrogen, CH 3 BCl 2 , (CH3) 2 PH, (CH 3 ) 3 Impurities such as CCl, such as hydrogen gas with a purity of 99.945% obtained after the tail gas in polysilicon production is processed, will be harmful to the quality of polysilicon if it is continued to be used in polysilicon production.

[0068]The purity of the tail gas in the polysilicon production in step (1) obtained after treatment is 99.945% impurity content in hydrogen: wherein, the total volume content of hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com