3D printer set for quickly manufacturing PCB (printed circuit board)

A printer group, 3D technology, applied in typewriters, printing devices, printing and other directions, can solve the problems of long PCB production cycle, low material utilization rate, expensive investment, etc., to save the total process time, high investment cost, and land occupation. large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

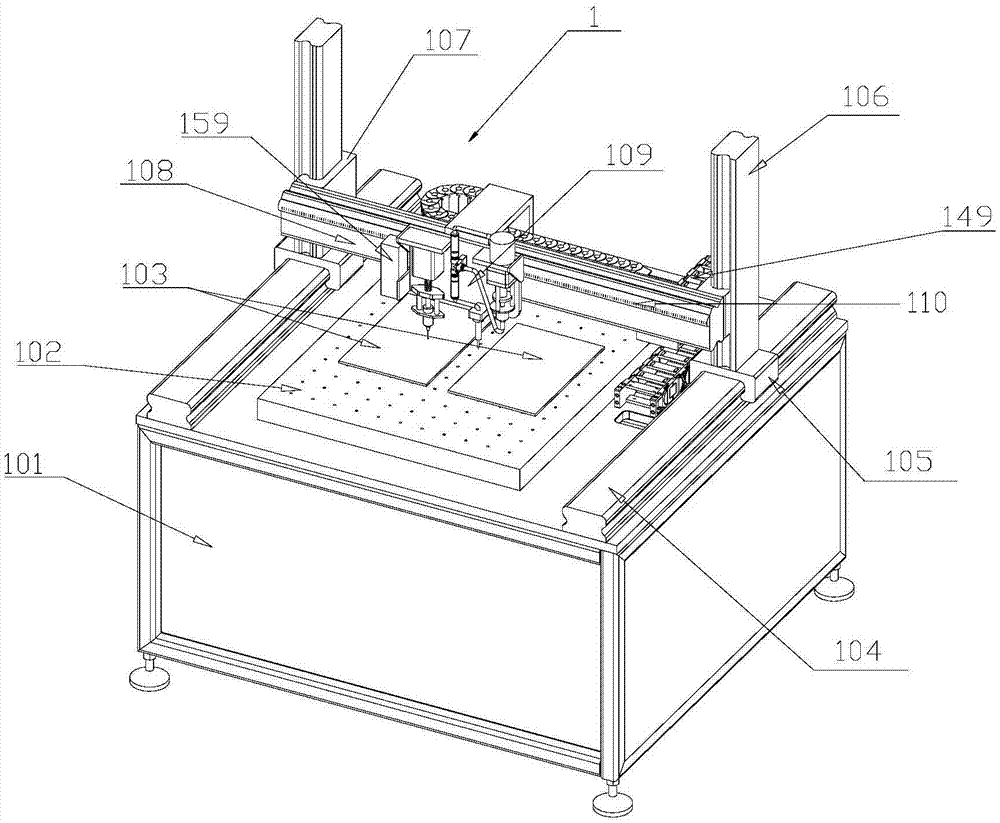

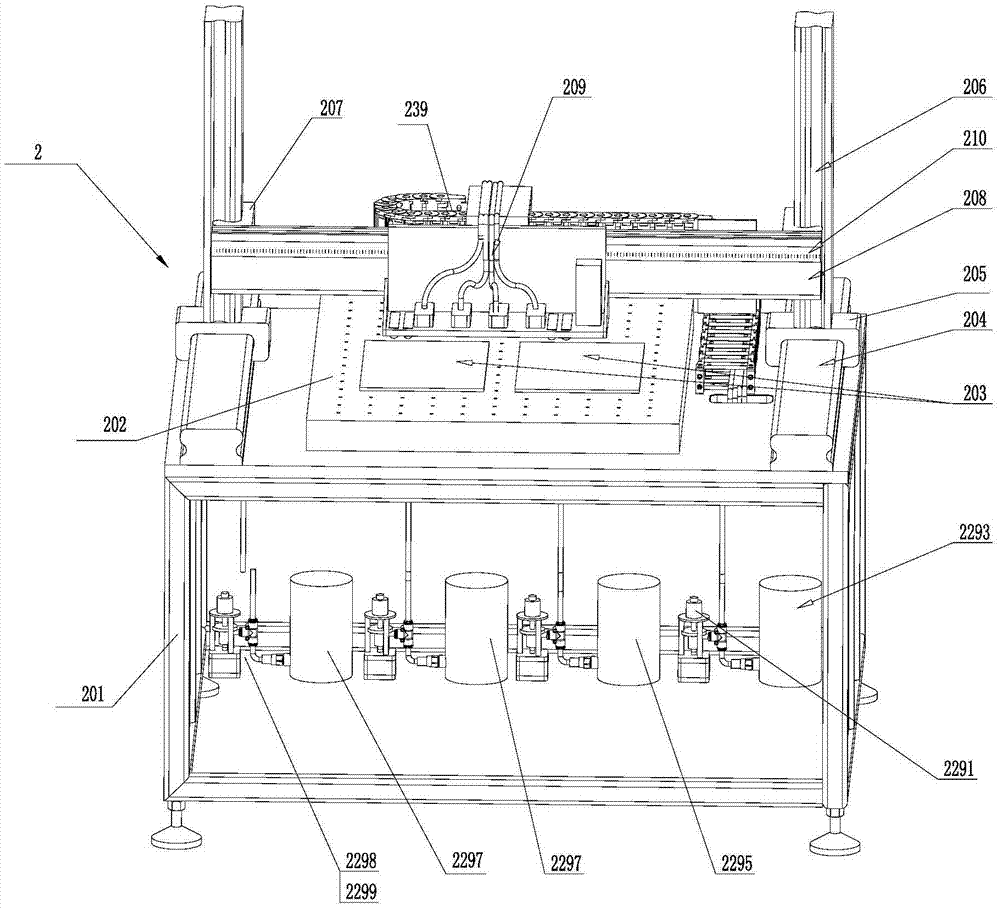

[0026] A 3D printer unit for rapid PCB manufacturing, including a drilling needle device 1, an inkjet character device 2, and a pressing device 3. The above three devices are all placed on a level ground and combined to form a 3D printer unit. The specific placement position It can be arranged arbitrarily according to actual needs.

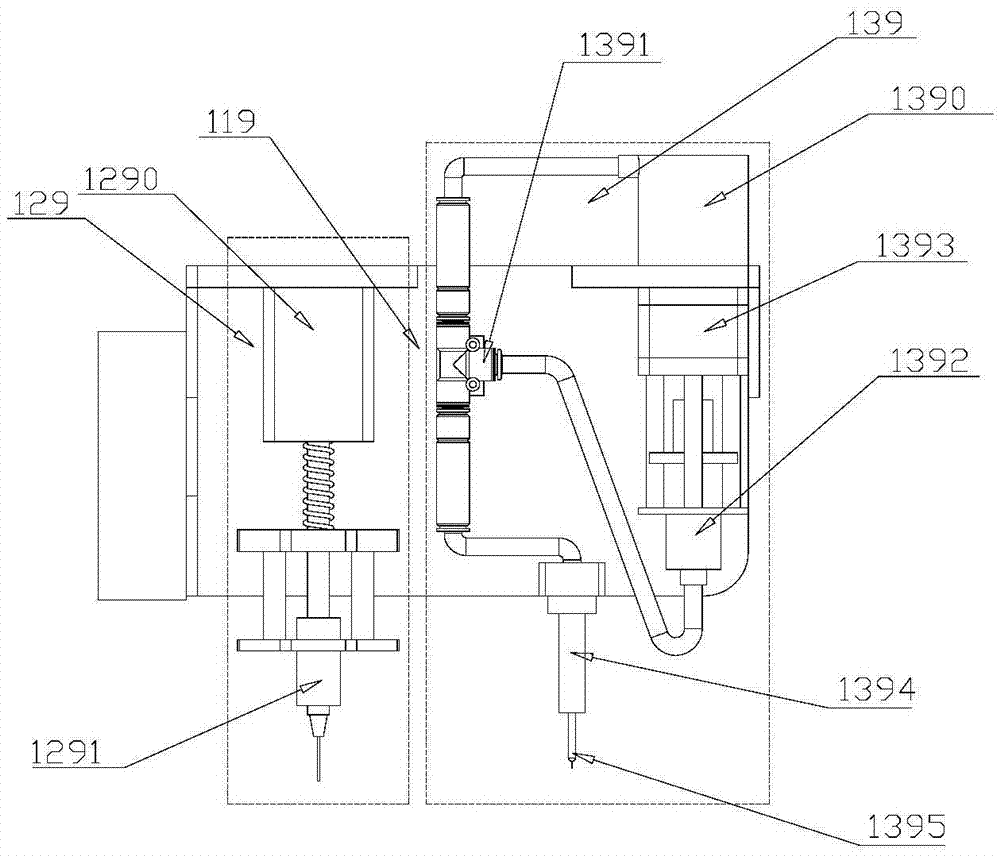

[0027] see figure 1 and figure 2 , the drilling needle equipment 1 includes a drilling needle chassis 101 and a three-dimensional driving device for the drilling needle. The top of the drilling needle cabinet is the drilling needle workbench 102, the upper surface of the drilling needle workbench is installed with the drilling needle substrate 103 for placing the PCB board, and the drilling needle workbench Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com