Manufacturing method of welding jig and target assembly

A technology for welding fixtures and manufacturing methods, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve the problems of long-term stable production and use of ceramic targets, poor welding bonding rate of target components, and concentricity Low-level problems, to achieve the effect of improving the welding combination rate, improving concentricity, and increasing alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

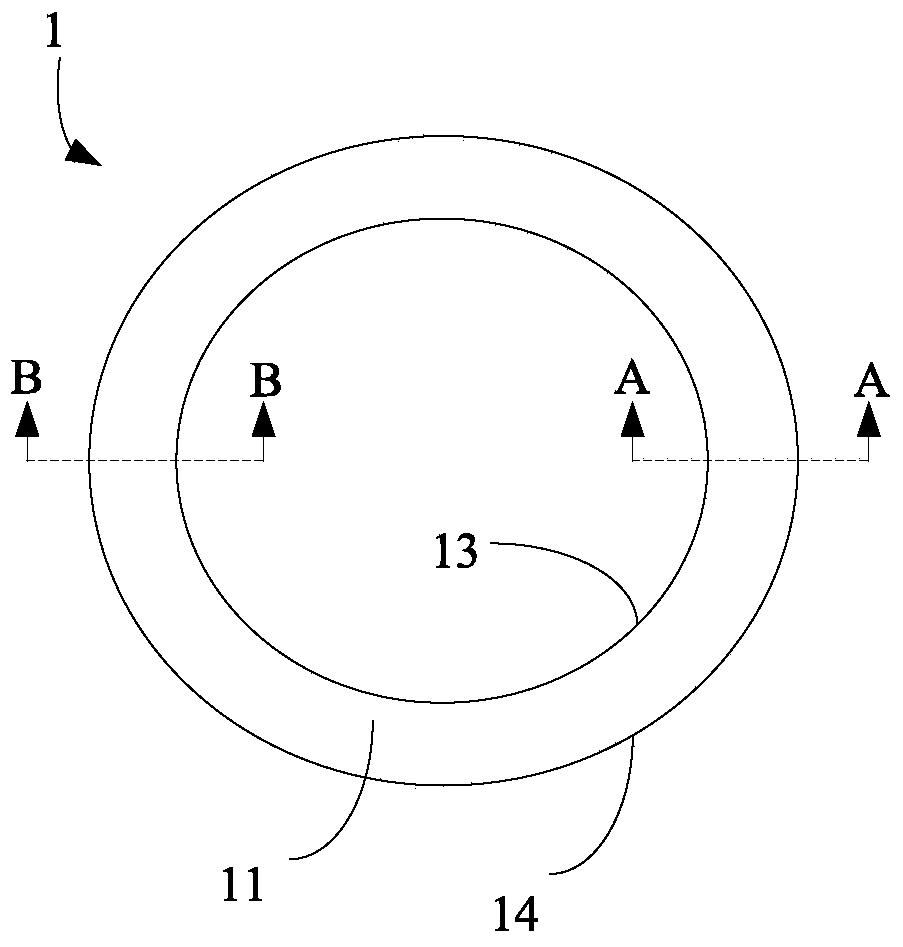

[0051] The present invention provides a welding jig 1 for welding a target and a back plate. The specific structure is as follows:

[0052] The first annular surface 11, the second annular surface 12 opposite to the first annular surface 11, the inner annular side 13 connected with the first annular surface 11 and the second annular surface 12, and the first annular surface 11 and the second annular surface 12 connected outer ring sides 14,

[0053] The inner ring side surface 13 includes a first inner ring side surface 131, and the first inner ring side surface 131 is connected to the first annular surface 11;

[0054] The second annular surface 12 has a groove 15, the bottom surface 151 of the groove is annular, and the opening size of the bottom surface 151 of the groove is larger than the size enclosed by the first inner ring side surface 131;

[0055]The inner ring side 13 also includes the second inner ring side 132, the groove bottom 151 and the first inner ring side ...

Embodiment 2

[0077] The present invention provides a method for manufacturing a target assembly, in which the jig of Embodiment 1 is applied in the manufacturing process of the target assembly. details as follows:

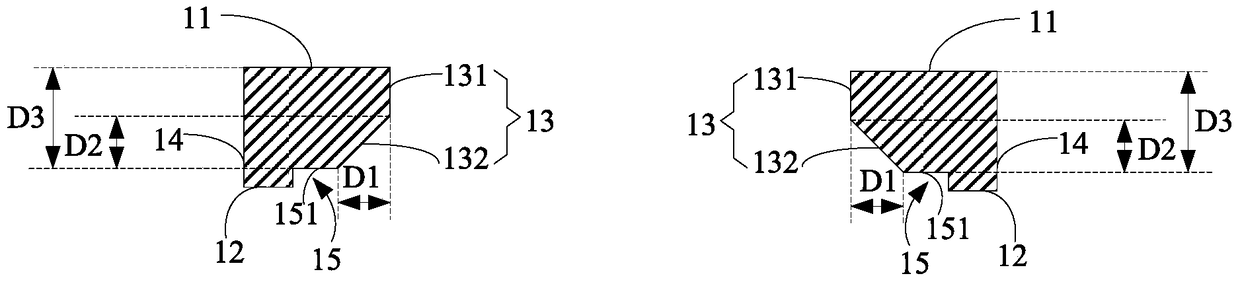

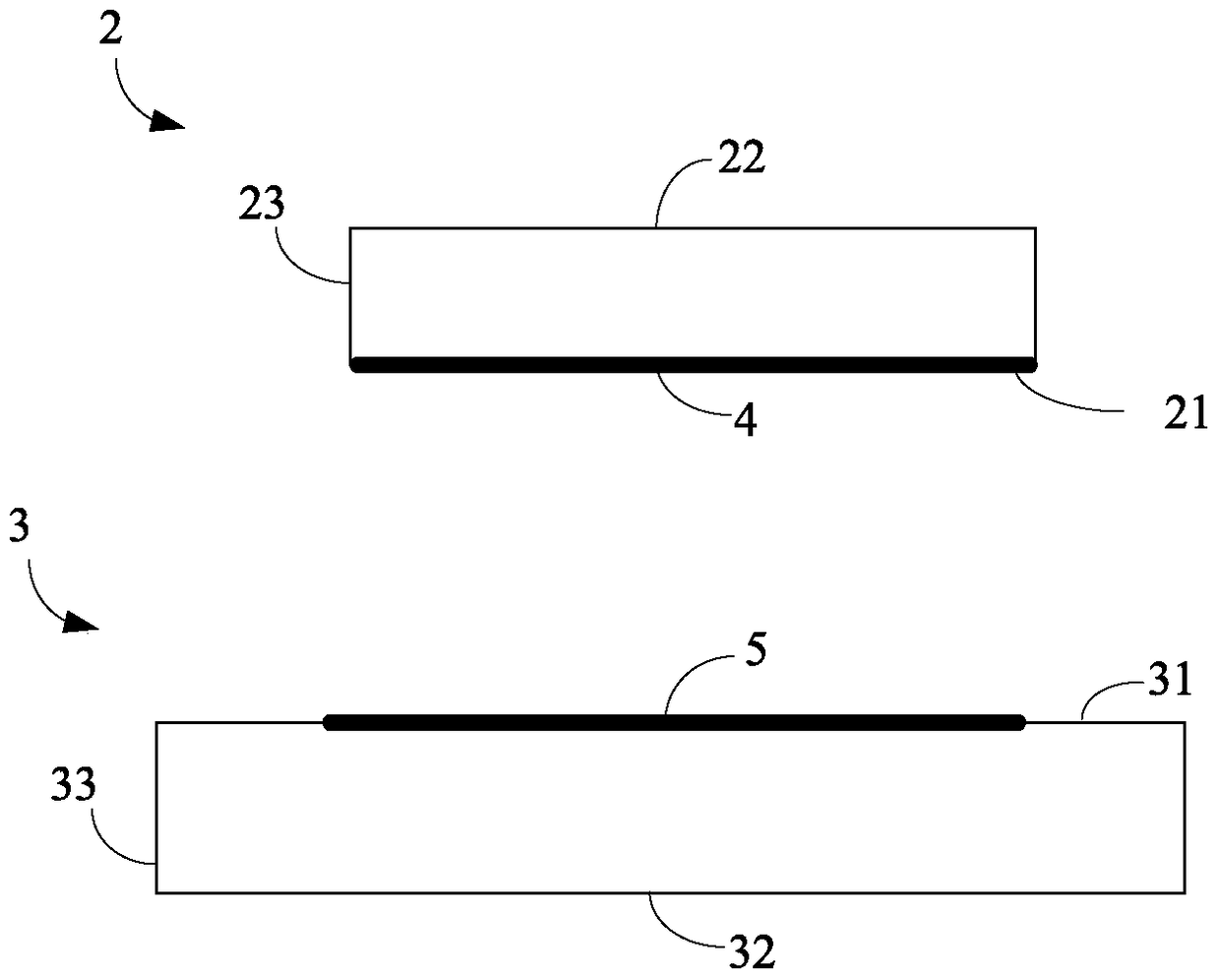

[0078] refer to image 3 , step S11 is executed to provide the target 2 , the back plate 3 and the welding jig 1 described in the first embodiment.

[0079] In this embodiment, the target material 2 is an ultra-high-purity and dense ceramic target material. Among them, the purity is at least 99.9%, and the density is at least 99%. According to the actual requirements of the application environment and sputtering equipment, the shape of the target 2 can be a cylinder, a cuboid, or a cube, and the cross-section can be a column of any one of a ring, a triangle, or other similar shapes (including regular shapes and irregular shapes). body.

[0080] refer to image 3 , in this embodiment, the target is a cylinder. The target 2 includes a target upper surface 22 , a target lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com